Preparation method of denitrification embedding immobilized granule

A particle and denitrification technology, applied in chemical instruments and methods, fixed on/in organic carriers, water/sludge/sewage treatment, etc. Problems such as mechanical nozzle clogging can be achieved to shorten the domestication time, reduce the difficulty of mechanized production, and increase the concentration of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

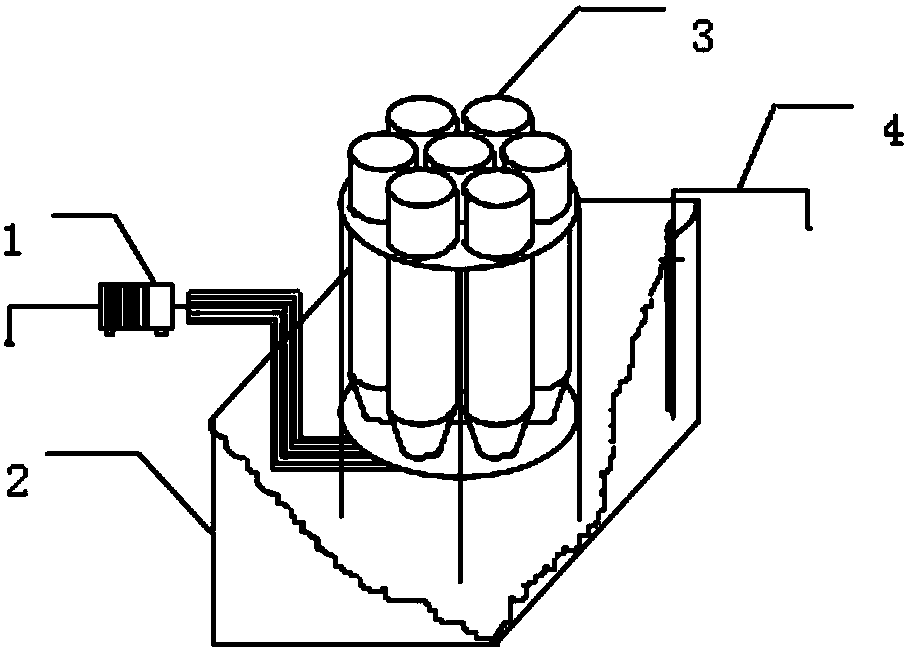

[0013] A preparation method for denitrification embedding and immobilization particles, the specific implementation steps are: under the condition of a water bath at about 98°C, mix polyvinyl alcohol with a mass percentage of 2% to 20% with water and dissolve it into a colloid, and simultaneously add 0.1%~5% sodium alginate, 0.1%~5% SiO 2 , stir evenly with a glass rod until completely dissolved to obtain PVA-SA hydrogel, cool to 15-35°C and mix evenly with microbial nitrifying bacteria agent at a mass ratio of 0.001:1-0.1:1, and finally drop the mixture into the Saturated boric acid is reacted with a cross-linking agent configured with aluminum sulfate, fixed at 1-10°C for 18-48 hours, washed with water, and dried at 35°C. The embedding particles are spherical, with a particle size of 3-5cm. They are resistant to compression, tough, not easy to break, and have a long service life.

[0014] Among them, the degree of polymerization of polyvinyl alcohol is 1750±50, SiO 2 The m...

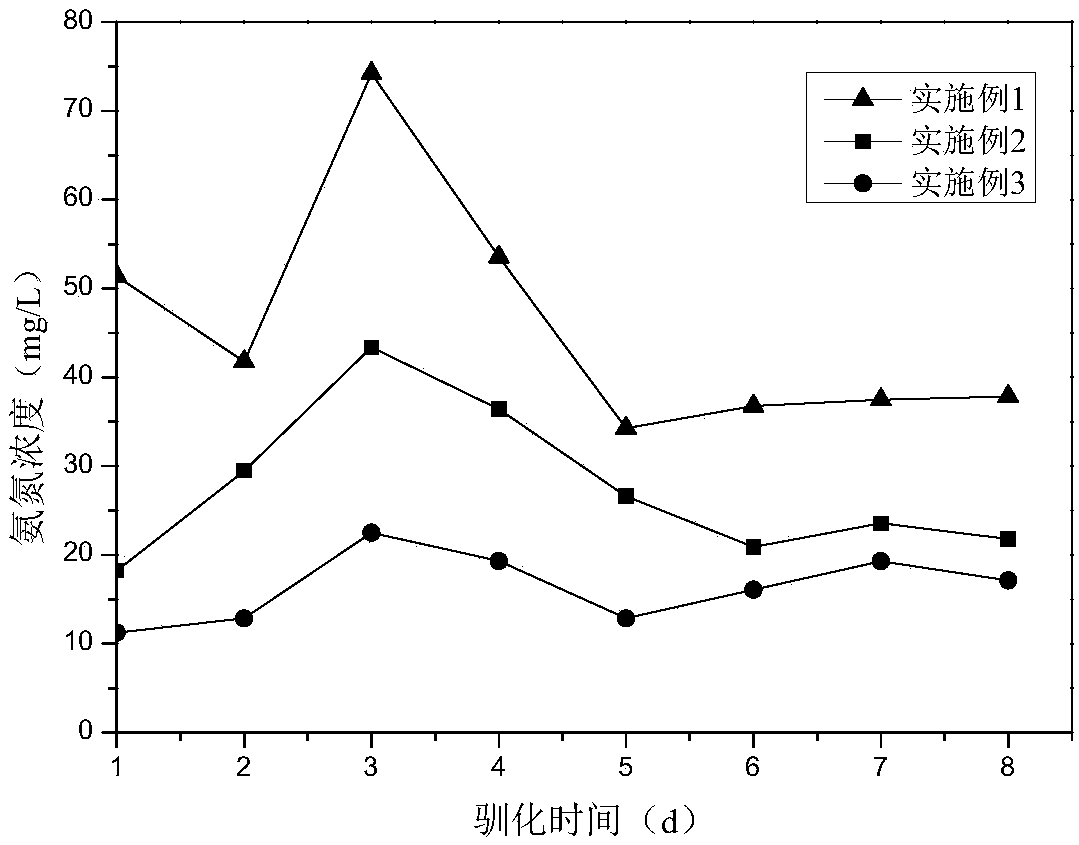

Embodiment 1

[0019] In a water bath at 100°C, mix 6g of polyvinyl alcohol (PVA) with 100g of water to dissolve into a colloid, and add 0.5g of sodium alginate (SA) and 0.5g of SiO 2 , stirred evenly with a glass rod until completely dissolved to prepare PVA-SA hydrogel, cooled to 30°C and mixed evenly with 0.5g microbial nitrifying bacteria agent, and finally dripped the mixture into a saturated boric acid solution containing aluminum sulfate with a syringe, Fix at low temperature for 24 hours, wash with water, dry at 35°C, soak in tap water and store at 4°C.

Embodiment 2

[0021] In a water bath at 100°C, mix 6g of polyvinyl alcohol (PVA) with 100g of water to dissolve into a colloid, and add 0.5g of sodium alginate (SA) and 0.5g of SiO 2 , stirred evenly with a glass rod until completely dissolved to prepare PVA-SA hydrogel, cooled to 30°C and mixed evenly with 2g of microbial nitrifying bacteria agent, and finally dripped the mixture into a saturated boric acid solution containing aluminum sulfate with a syringe, at low temperature Fix it under the sun for 24 hours, wash it with water, dry it at 35°C, soak it in tap water and store it at 4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com