Electromagnetic wave absorber based on refractory material

A refractory material and absorber technology, applied in instruments, optical components, optics, etc., can solve the problems of strong ohmic loss and thermal effect, inability to achieve broadband light absorption, poor structural stability of precious metal micro-nano materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

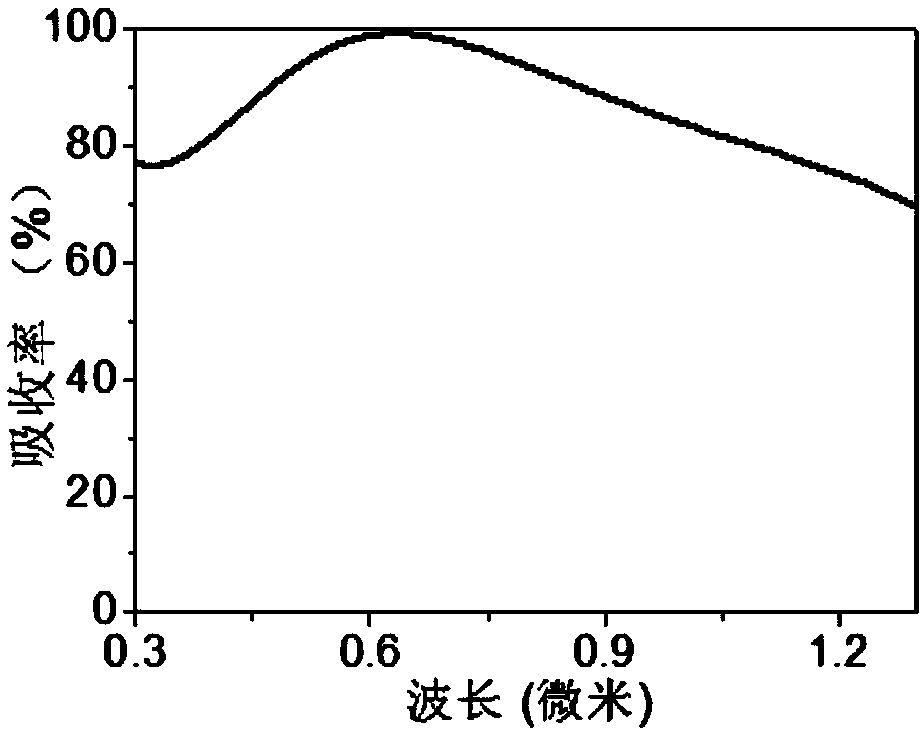

[0047] figure 2 Shown is a light absorption diagram of an embodiment of the electromagnetic wave absorber based on refractory materials of the present invention. The particle structure layer only contains an array of tungsten cylindrical particles of one size. The substrate is a silicon wafer, and the thickness of the tungsten film is 100 nanometers. The material of the dielectric film layer is aluminum oxide with a thickness of 40 nanometers. The particle diameter in the tungsten cylindrical particle array is 100 nanometers and the thickness is 40 nanometers. The particle array is a square array with a lattice constant of 150 nanometers.

[0048] From figure 2 It can be determined from the spectrogram shown that the absorption rate at a wavelength of 0.634 microns reaches a maximum of 99.4%. In the spectral range from 0.469 microns to 0.867 microns, a wide-band perfect absorption spectrum with an absorption rate of over 90% is produced, that is, the perfect absorption bandw...

Embodiment 2

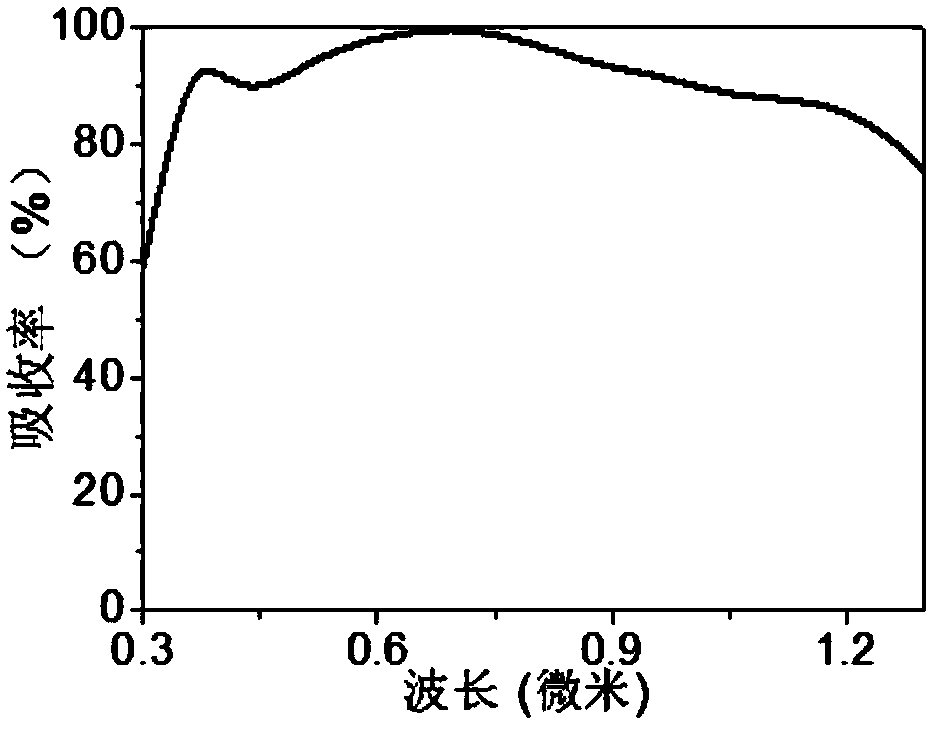

[0050] image 3 Shown is the light absorption diagram of the second embodiment of the electromagnetic wave absorber based on refractory materials of the present invention. The particle structure layer only contains an array of vanadium cylindrical particles of one size. The substrate is a silicon wafer, and the thickness of the vanadium film is 100 nanometers. The material of the dielectric film layer is aluminum oxide with a thickness of 40 nanometers. The particle diameter in the vanadium cylinder particle array is 100 nanometers and the thickness is 40 nanometers. The particle array is a square array with a lattice constant of 150 nanometers.

[0051] From image 3 It can be determined from the spectrogram shown that the absorption rate at the wavelength of 0.684 microns reaches the maximum value of 99.7%. In the spectral range from 0.360 microns to 1.008 microns, a wide-band perfect absorption spectrum with an absorption rate of over 90% is produced, that is, the perfect a...

Embodiment 3

[0053] Figure 4 Shown are the three light absorption diagrams of the embodiment of the electromagnetic wave absorber based on refractory materials of the present invention. The particle structure layer only contains an array of tantalum cylinder particles of one size. The substrate is a quartz plate, and the thickness of the tantalum film is 100 nanometers. The material of the dielectric film layer is aluminum oxide with a thickness of 40 nanometers. The diameter of the particles in the tantalum cylinder particle array is 100 nanometers and the thickness is 40 nanometers. The particle array is a square array with a lattice constant of 150 nanometers. The absorption rate at a wavelength of 0.616 microns reaches a maximum of 98.8%.

[0054] From Figure 4 It can be determined from the spectrogram shown that a wide-band perfect absorption spectrum with an absorption rate of over 90% is generated in the spectral range from 0.461 microns to 0.951 microns, that is, the perfect abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com