Winding type multi-lug battery and terminal

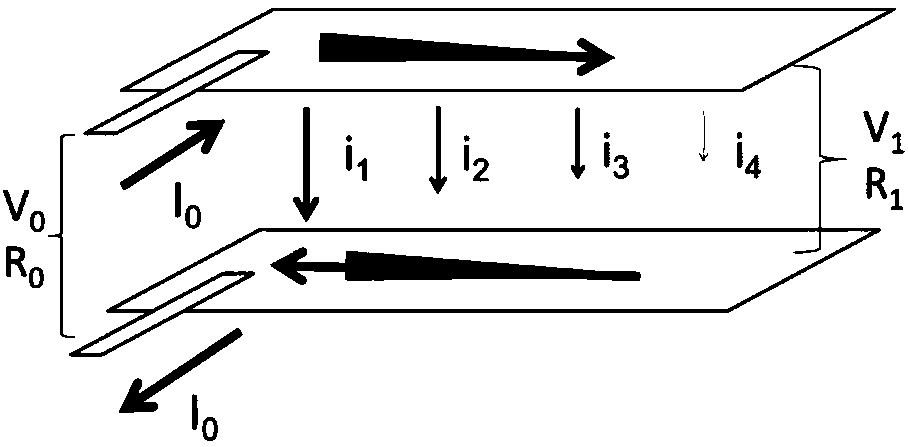

A wound-type, multi-tab technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary battery repair/maintenance, etc., can solve problems such as difficult to control, difficult to detect, uneven impedance distribution, etc., to achieve good monitoring, The effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation of the positive pole piece: the positive active material lithium cobaltate, the binder polyvinylidene fluoride (PVDF) and the conductive agent Super-P are added to N-methylpyrrolidone (NMP) according to the weight ratio of 96:2:2 and stirred evenly The slurry is made into positive electrode slurry; the positive electrode slurry is double-coated on the positive electrode current collector, and the positive electrode sheet is obtained after drying, compacting, slitting, cutting, and welding tabs.

[0044]Preparation of negative electrode sheet: Negative electrode active materials artificial graphite, styrene-butadiene rubber (SBR), sodium carboxymethyl cellulose (CMC), add deionized water according to the ratio of 95:2.5:2.5 and stir to make negative electrode slurry; The negative electrode slurry is double-coated on the negative electrode current collector, and the negative electrode sheet is obtained after drying, compacting, slitting, cutting, and welding ta...

Embodiment 1

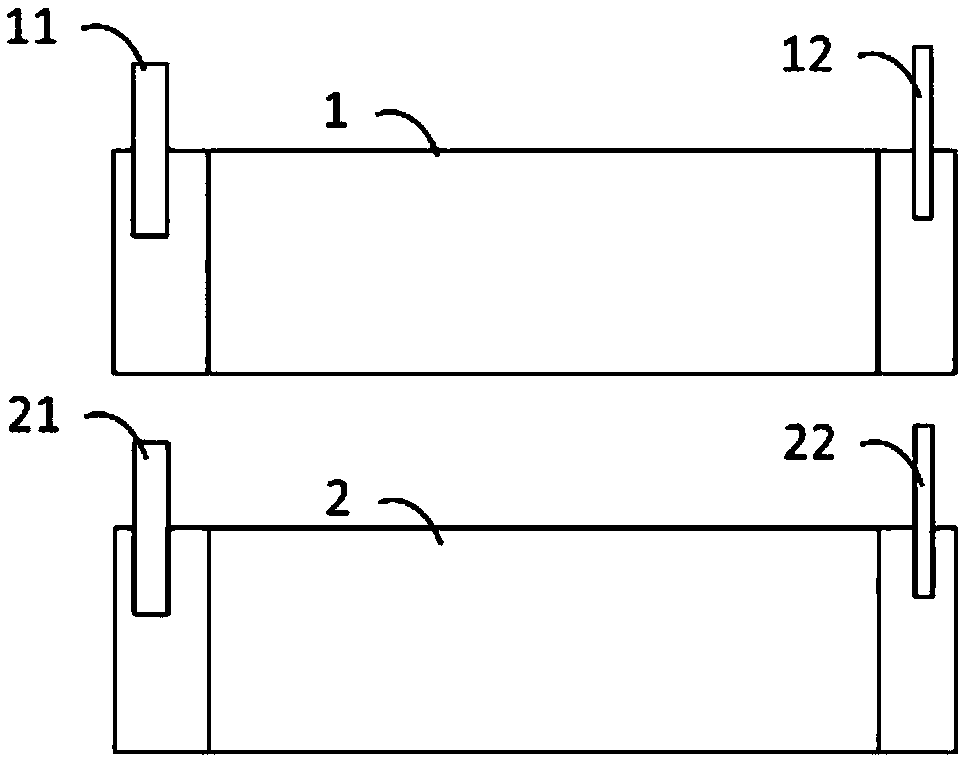

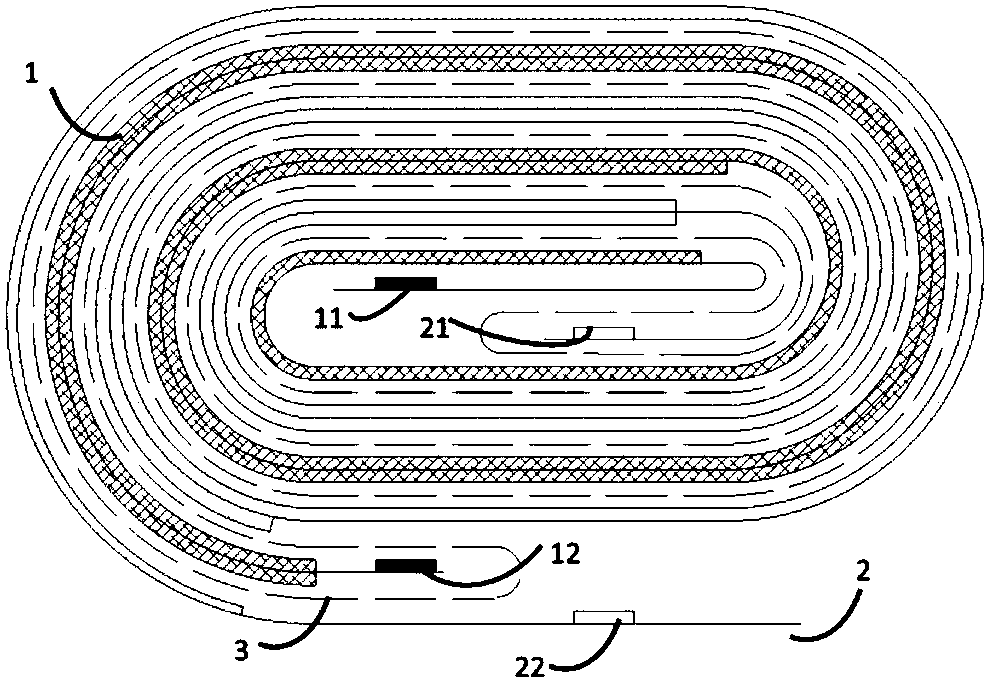

[0050] Pole piece structure such as figure 2 As shown, it includes a first electrode sheet 1, a first negative tab 11, a second negative tab 12, a second electrode sheet 2, a first positive tab 21, and a second positive tab 22. The first negative tab 11 and the second negative tab 12 are respectively located at both ends of the first electrode sheet 1 , and the first positive tab 21 and the second positive tab 22 are respectively located at both ends of the second electrode sheet 2 . figure 2 The electrode and separator of the structure are wound to form a core such as image 3 As shown, the winding core can be obtained by putting the winding core in aluminum-plastic film for packaging, injecting liquid, and forming Figure 4 The wound multi-tab cell shown.

Embodiment 2

[0052] Pole piece structure such as Figure 5 As shown, it includes a first electrode sheet 1, a first negative tab 11, a second negative tab 12, a second electrode sheet 2, a first positive tab 21, and a second positive tab 22. The first negative tab 11 and the second negative tab 12 are respectively located at both ends of the first electrode sheet 1 , and the first positive tab 21 and the second positive tab 22 are respectively located at both ends of the second electrode sheet 2 . Figure 5 The electrode and separator of the structure are wound to form a core such as image 3 As shown, the winding core can be obtained by putting the winding core in aluminum-plastic film for packaging, injecting liquid, and forming Figure 6 The wound multi-tab cell shown. Figure 6 The wound multi-tab battery shown is assembled and matched, and can be obtained as follows Figure 10 terminal as shown. This terminal includes Figure 6 Shown are batteries, at least two battery connectors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com