Waste rubber low-temperature efficient compound regeneration activating agent

A regenerative activator and compound regeneration technology, applied in the field of regenerated rubber, can solve the problems of stickiness, unfavorable automatic weighing and transportation, poor performance of reclaimed rubber, pollution of the environment, etc., and achieve easy automatic weighing and transportation, viscosity stability good effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

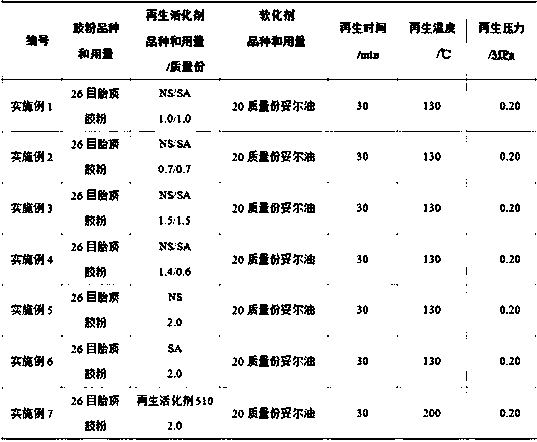

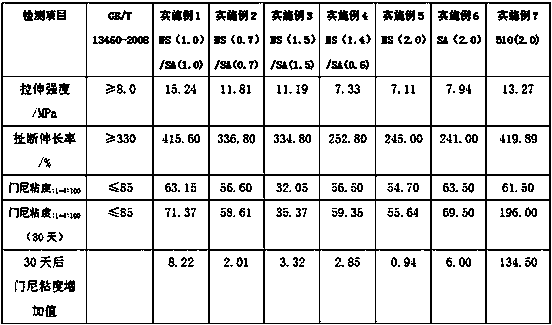

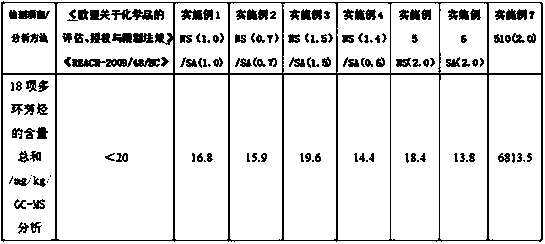

Embodiment 1

[0019] Put 50 parts by mass of the main regenerative activator NS into a heating agitator at a stirring speed of 100-200 rpm, and heat to 50-90°C while stirring; then add 50 parts by mass of stearic acid into the agitator Mix and stir at 50-90°C for 5 minutes; stop heating, continue stirring, and wait for the temperature of the material to drop to room temperature, and let it stand for 1-1.5 hours to obtain a powdery composite regeneration activator.

[0020] Add 2 parts by mass of the composite regeneration activator to 100 parts by mass of 26-mesh tire top rubber powder on an open mill and disperse evenly for 1 min to obtain activated rubber powder. Then add 20.0 parts by mass of tall oil to 102 parts by mass of activated rubber powder in the desulfurization tank, and then add 20 parts by mass of water to generate a regeneration pressure of 0.20MPa, desulfurize and regenerate at the regeneration pressure and regeneration temperature (130±5°C) 30min, then cool down to 70°C an...

Embodiment 2

[0022] Put 50 parts by mass of regenerated activator NS into a heating agitator at a stirring speed of 100-200 rpm, and heat to 50-90°C while stirring; then add 50 parts by mass of stearic acid into the agitator Mix and stir for 5 minutes at 50-90°C; stop heating, continue stirring, and wait for the temperature of the material to drop to room temperature, and let it stand for 1-1.5 hours to obtain a powdery composite regeneration activator.

[0023] Add 1.4 parts by mass of the composite regeneration activator to 100 parts by mass of 26-mesh tire top rubber powder on an open mill and uniformly disperse for 1 min to obtain activated rubber powder. Then add 20.0 parts by mass of tall oil to 102 parts by mass of activated rubber powder in the desulfurization tank, and then add 20 parts by mass of water to generate a regeneration pressure of 0.20MPa, desulfurize and regenerate at the regeneration pressure and regeneration temperature (130±5°C) 30min, then cool down to 70°C and dis...

Embodiment 3

[0025] Put 50 parts by mass of regenerated activator NS into a heating agitator at a stirring speed of 100-200 rpm, and heat to 50-90°C while stirring; then add 50 parts by mass of stearic acid into the agitator Mix and stir for 5 minutes at 50-90°C; stop heating, continue stirring, and wait for the temperature of the material to drop to room temperature, and let it stand for 1-1.5 hours to obtain a powdery composite regeneration activator.

[0026] Add 3.0 parts by mass of the composite regeneration activator to 100 parts by mass of 26-mesh tire top rubber powder on an open mill and uniformly disperse for 1 min to obtain activated rubber powder. Then add 20.0 parts by mass of tall oil to 102 parts by mass of activated rubber powder in the desulfurization tank, and then add 20 parts by mass of water to generate a regeneration pressure of 0.20MPa, desulfurize and regenerate at the regeneration pressure and regeneration temperature (130±5°C) 30min, then cool down to 70°C and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com