Multifunctional grain dryer

A grain dryer, multi-functional technology, applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problem of single function, achieve uniform heating, ensure the effect, and optimize the effect of turning and stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

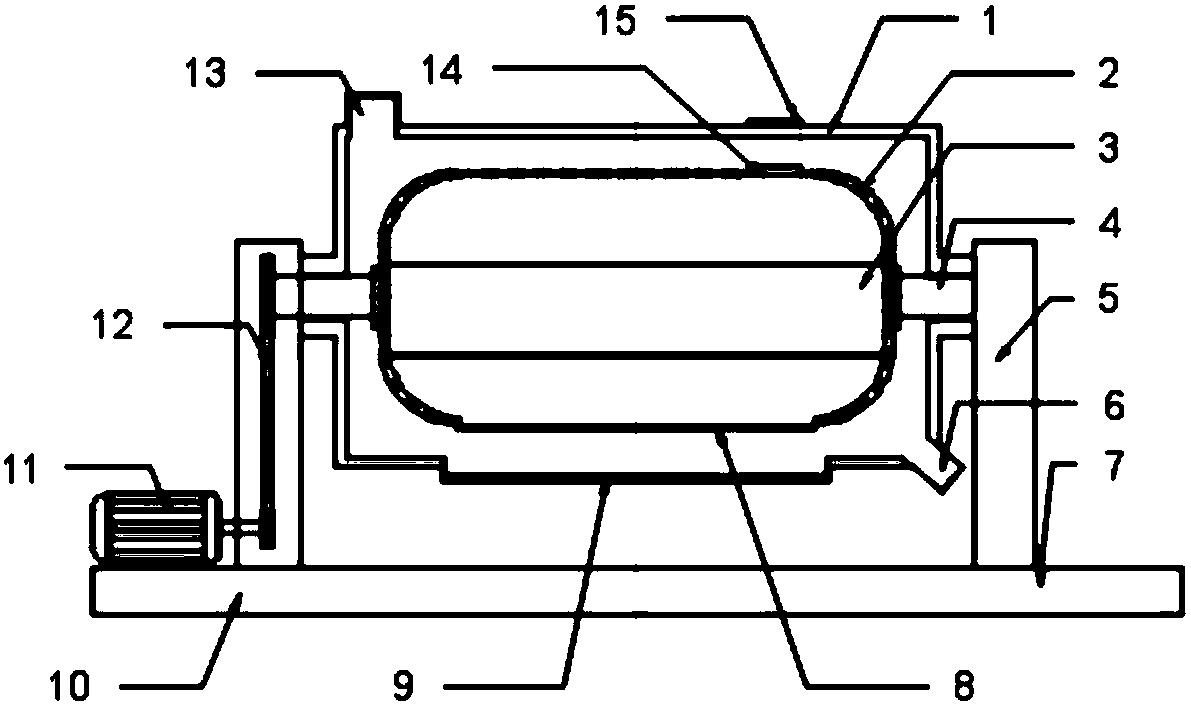

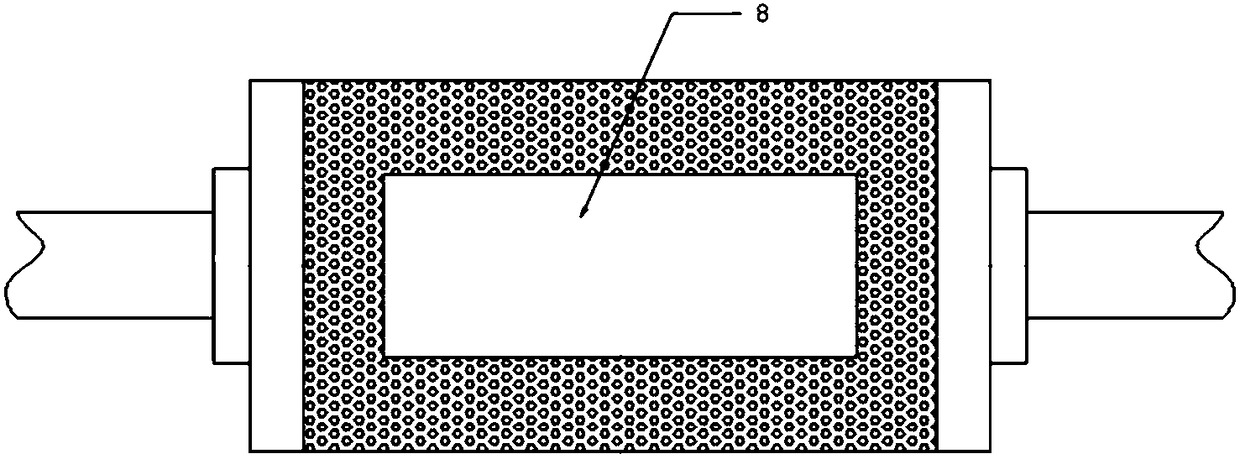

[0038] A multifunctional grain dryer, including a support system, a power system and a multifunctional drying system; the support system includes a base 7 and two pillars 5 installed on the base 7; the power system includes a 10 above the motor 11 and transmission system 12; the multifunctional drying system adopts a double-tube structure, including an outer cylinder 1 fixed on the pillar 5 and a drying cylinder installed in the outer cylinder 1; the bottom of the outer cylinder 1 An outer cylinder outlet 9 is arranged in the center, and an outer cylinder inlet 15 is arranged at the top; an air inlet 6 is arranged at the foot of one side of the outer cylinder 1, and an air outlet 13 is arranged at the top corner of the other side; The opening of the air inlet 6 is horizontally downward; the drying cylinder includes a cylinder 2 with a screen hole on the cylindrical surface, a sieve plate 3 and two shafts 4 fixed at both ends of the cylinder 2 and connected to the pillar; the si...

Embodiment 2

[0040] Based on Embodiment 1, in order to optimize the balance between the negative pressure effect generated by the air flow and the screening effect of lighter impurities, the following improvements were made: the acute angle between the central axis of the air inlet 6 and the straight line where the bottom edge of the outer cylinder 1 is The tangent is equal to the ratio of the diameter to the length of the cylindrical surface of the outer cylinder.

[0041] After repeated tests and verification, when the acute angle between the central axis of the air inlet and the straight line where the bottom edge of the outer cylinder is located is the above ratio, it is not only conducive to the extraction of humid air in the drying cylinder, but also ensures the drying effect; Insufficient air flow on the lower surface of the cylinder and the insufficient negative pressure formed result in the backflow of light impurities such as dust and dry broken leaves, which ensures the effect of...

Embodiment 3

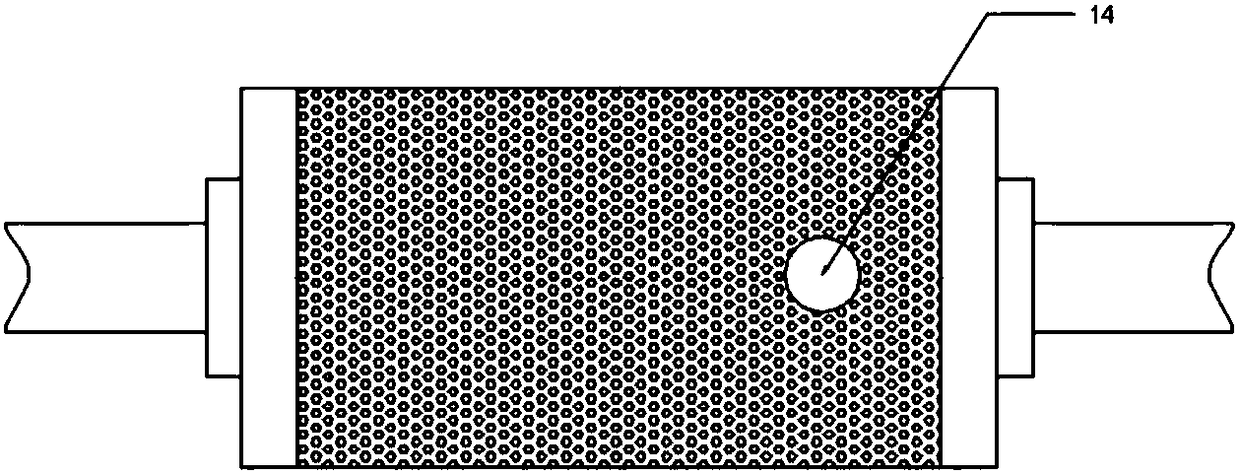

[0043] Based on Example 1, in order to optimize the removal effect of attached impurities and the effect of stirring and dispersing grain particles, the following improvements were made: the sieve plate 3 is provided with a single-shaped sieve hole; the sieve hole is a rhombus mesh.

[0044] When a diamond-shaped mesh is designed on the sieve plate, with the rotation of the drying cylinder, the grain particles at a high place are blocked by the sieve plate, and when they slide and roll down on the sieve plate, part of the grain particles flow along the diamond-shaped mesh. Some of the holes fall down, and the other part continues to roll down along the sieve plate. In this way, the further dispersion of the grain particles is realized, the overall heating area and heating uniformity of the grain particles are improved, and the drying effect of the grain particles is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com