Preparation method and application of cobalt-based sulfide nanosphere carbon fiber integrally comprising core-shell structure

A core-shell structure, nano-sphere technology, applied in structural parts, electrochemical generators, electrical components, etc., can solve the problems of material capacity attenuation, material pulverization and shedding, etc., to improve energy density, alleviate material pulverization, prolong Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Prepare 30ml of glycerol and isopropanol at a volume ratio of 1:10 and mix them into the solution, stir evenly, then add 2mmol of cobalt nitrate hexahydrate, stir until the solution is clear, then transfer to a 50ml hydrothermal reaction kettle, 180°C Insulate for 10 hours, cool down, centrifuge, wash and dry. Take 0.3g of the dried product, add 2ml of DMF solution, ultrasonically disperse for 20min, then add 0.2g of PAN, and stir for 24h. Then the prepared solution was transferred to a 5ml jet pump and spun with a positive high pressure of 10kV. Finally, the product obtained by spinning is transferred to a tube furnace to add sulfur source under the protection of Ar gas atmosphere. Different quality of sulfur source, different calcination temperature and holding time will obtain cobalt-based sulfides with different stoichiometric ratios.

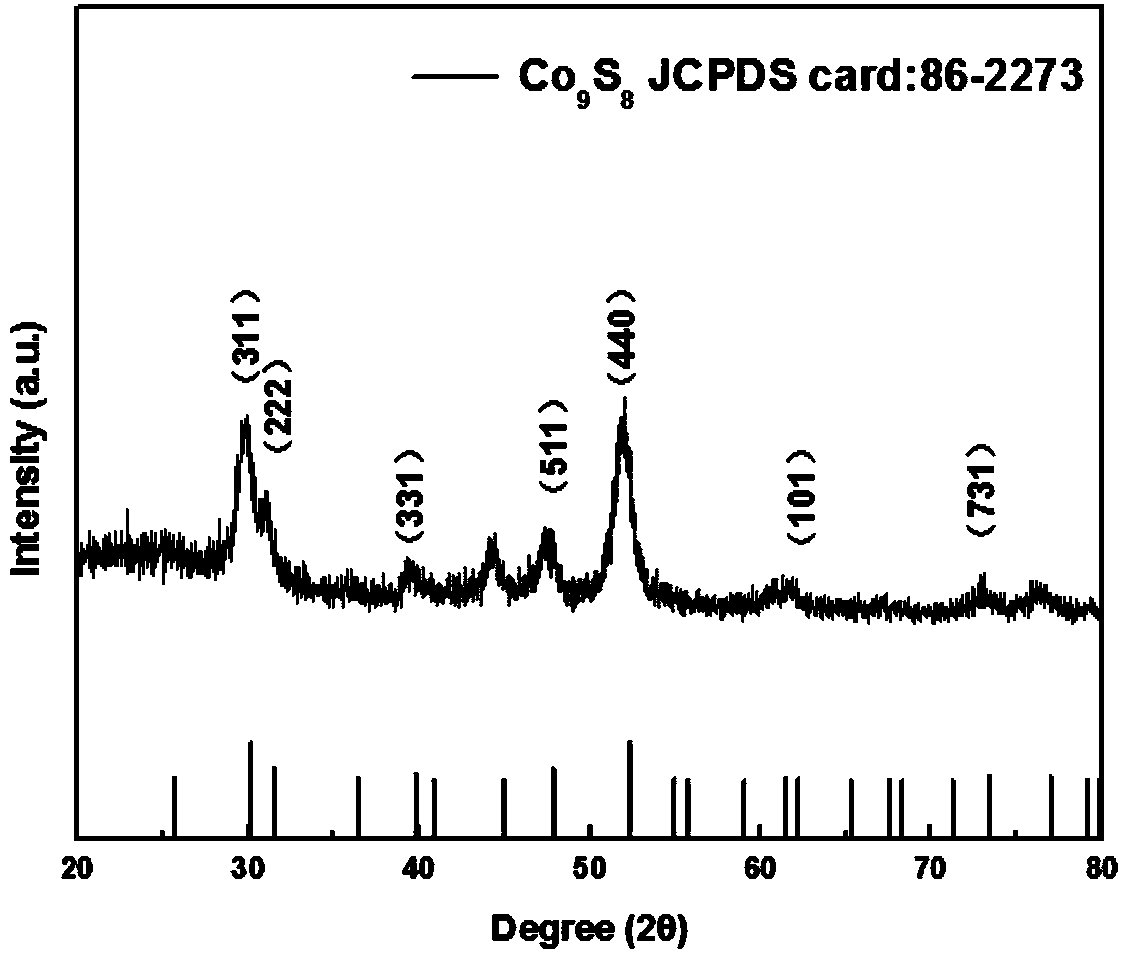

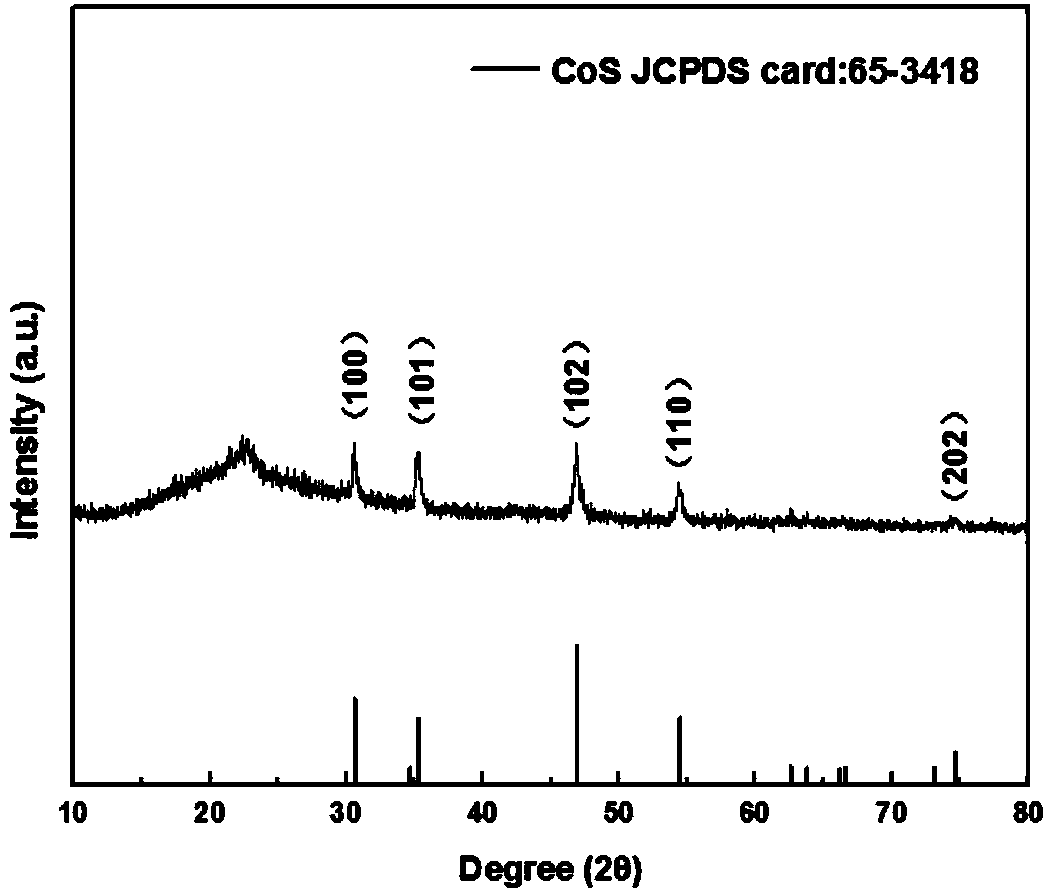

[0063] (1) Using sulfur powder as the sulfur source, when N (S) :N (Co) When =1.2:1, be heated up to 700 ℃ with 5 ℃ / min heating ...

Embodiment 2

[0073] Prepare 30ml of glycerol and isobutanol with a volume ratio of 1:12 and mix them into the solution, stir evenly, then add 2.5mmol cobalt nitrate hexahydrate, stir until the solution is clear, then transfer to a 50ml hydrothermal reaction kettle, 200 ℃ for 12 hours, after cooling down, centrifuge, wash and dry. Using the NovaNanoSEM 230 scanning electron microscope of FEI Company in the United States to observe the sample, it was found that the cobalt precursor nanoparticles have regular shape, good dispersion and consistency, and are suitable for the next step of electrospinning. The scanned picture is as follows Figure 11 shown.

Embodiment 3

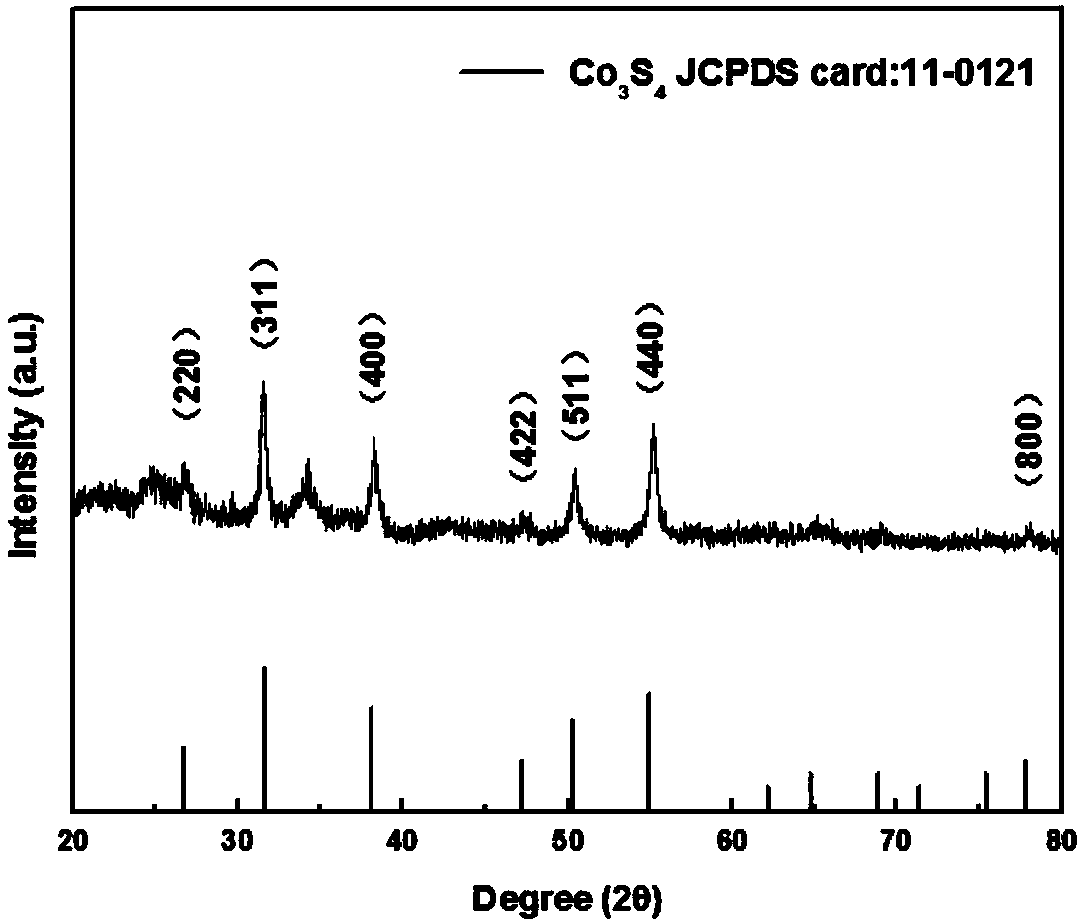

[0075] Prepare 30ml of glycerol and isobutanol at a volume ratio of 1:15 and mix them into the solution, stir evenly, then add 3mmol of cobalt nitrate hexahydrate, stir until the solution is clear, then transfer to a 50ml hydrothermal reaction kettle, 160°C Insulate for 10 hours, cool down, centrifuge, wash and dry. Take 0.2 g of the dried product, add 5 ml of DMF solution, ultrasonically disperse for 20 min, then add 0.5 g of PAN, and stir for 24 h. Then the prepared solution was transferred to a 10ml jet pump and spun with a positive high pressure of 15kV. Finally, the product obtained by spinning was transferred to a tube furnace under the protection of an Ar gas atmosphere, and was heated with N (S) :N (C o) = Add sulfur powder at a ratio of 8:1, heat up at 3°C / min to 600°C for 2 hours, and obtain a carbon fiber-coated core-shell structure Co 3 S 4 nanospheres. Such as Figure 12 As shown, the sample was observed with a Nova NanoSEM 230 scanning electron microscope f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com