Surface-enhanced Raman substrate microspheres with micron size and preparation method thereof

A surface-enhanced Raman and surface-enhanced technology, which is applied in the field of composite materials, can solve the problems that cannot be distinguished and positioned one by one, cannot be moved to the designated position, and the individual cannot be operated, so as to reduce low reproducibility and inaccurate The effects of stability, uniform size, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

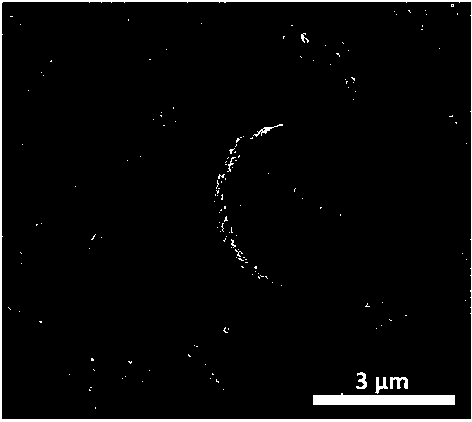

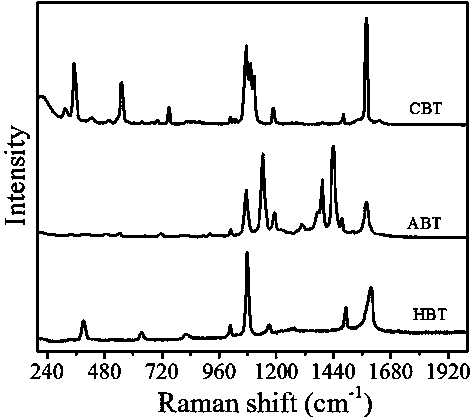

Image

Examples

Embodiment 1

[0016] (1) Mix 5.0 g GMA, 1.0 g PVP, 87 mL ethanol, 13 mL ionized water, 0.1 g AIBN and fluorescent probe molecules, react at 70 °C for 12 h, centrifuge to separate the product, and then dry it in vacuum at 50 °C for 2 h obtains PGMA microspheres;

[0017] (2) Add 10 mg of PGMA microspheres obtained in step (1) to 50 mL of 5 mg AgNO 3 Add 0.05 g of cuprous oxide to the ethanol solution, then place it in a shaker, shake it at 50°C for 60 min, wash it with ethanol for 2-3 times after centrifugation, and dry it in vacuum at 50°C for 2 h to obtain PGMA / Ag- NPs substrate microspheres.

Embodiment 2

[0019] (1) Mix 5.0 g GMA, 1.0 g PVP, 87 mL ethanol, 13 mL ionized water, 0.1 g AIBN, and fluorescent probe molecules, react at 70 °C for 12 h, centrifuge to separate the product, and then dry it in vacuum at 50 °C for 2 h obtains PGMA microspheres;

[0020] (2) Add 10 mg of PGMA microspheres obtained in step (1) to 50 mL of 20 mg AgNO 3 Add 0.1 g of cuprous chloride to the ethanol solution, then place it in a shaker, shake it at 50°C for 60 min, wash it with ethanol for 2-3 times after centrifugation, and dry it in vacuum at 50°C for 2 h to obtain PGMA / Ag -NPs substrate microspheres;

Embodiment 3

[0022] (1) Mix 5.0 g GMA, 1.0 g PVP, 87 mL ethanol, 13 mL ionized water, 0.1 g AIBN, and fluorescent probe molecules, react at 70 °C for 12 h, centrifuge to separate the product, and then dry it in vacuum at 50 °C for 2 h obtains PGMA microspheres;

[0023] (2) Add 10 mg of PGMA microspheres obtained in step (1) to 50 mL of 50 mg AgNO 3 Add 0.4 g of n-butylamine to the ethanol solution, then place it in a shaker, shake it at 50°C for 60 min, wash it with ethanol for 2-3 times after centrifugation, and dry it in vacuum at 50°C for 2 h to obtain PGMA / Ag- NPs substrate microspheres;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com