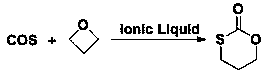

Method for preparing trimethylene monothiocarbonate by ionic liquid catalysis

A technology of trimethylene monothiocarbonate and methyl monothiocarbonate is applied in the field of ionic liquid catalyzed preparation of trimethylene monothiocarbonate, and can solve the problems that ionic liquid catalysts have not been developed and applied, and the like, Achieve the effect of improving selectivity and conversion rate, simple operation and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

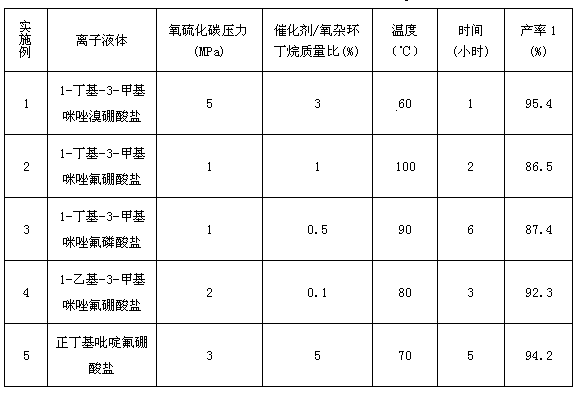

[0018] Add 2 grams of oxetane in a 10ml autoclave, add 1-butyl-3-methylimidazolium bromide borate ionic liquid catalyst according to 3% of the mass of oxetane, stir evenly, pass into Carbonyl sulfide to 5 MPa pressure, react at 60°C for 1 hour, slowly release gas after cooling to room temperature, filter to obtain crude product liquid, obtain trimethylene monothiocarbonate through vacuum distillation, and produce Rate, trimethylene monothiocarbonate product yield results are shown in Table 1 below.

Embodiment 2

[0020] Add 2 grams of oxetane into a 10ml autoclave, add 1-butyl-3-methylimidazolium fluoroborate ionic liquid catalyst according to 1% of the mass of oxetane, stir evenly, pass into Carbonyl sulfide to a pressure of 1 MPa, reacted at 100°C for 2 hours, cooled to room temperature and slowly released gas, filtered to obtain a crude product liquid, and obtained trimethylene monothiocarbonate by distillation under reduced pressure. Rate, trimethylene monothiocarbonate product yield results are shown in Table 1 below.

Embodiment 3

[0022] Add 2 grams of oxetane in a 10ml autoclave, add 1-butyl-3-methylimidazolium fluorophosphate ionic liquid catalyst according to 0.5% of the mass of oxetane, stir evenly, and feed oxygen Sulfurize carbon to a pressure of 1 MPa, react at 90°C for 6 hours, slowly release gas after cooling to room temperature, filter to obtain a crude product liquid, and obtain trimethylene monothiocarbonate by distillation under reduced pressure, and measure the yield by proton nuclear magnetic spectrum , The product yield results of trimethylene monothiocarbonate are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com