Method for making base asphalt warm mix regenerant

A technology of warm-mixing regenerant and matrix asphalt, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of secondary aging, high heating temperature of mixture, and shorten the service life of mixing equipment, so as to reduce energy consumption and pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

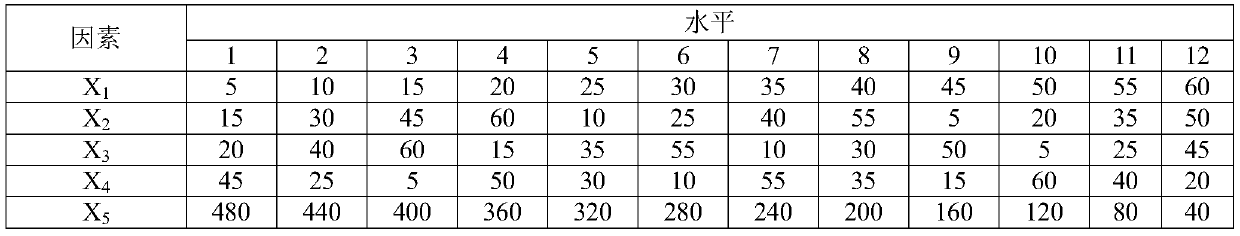

[0016] A method for making base asphalt warm-mix regenerant, the innovation of which is that the method includes:

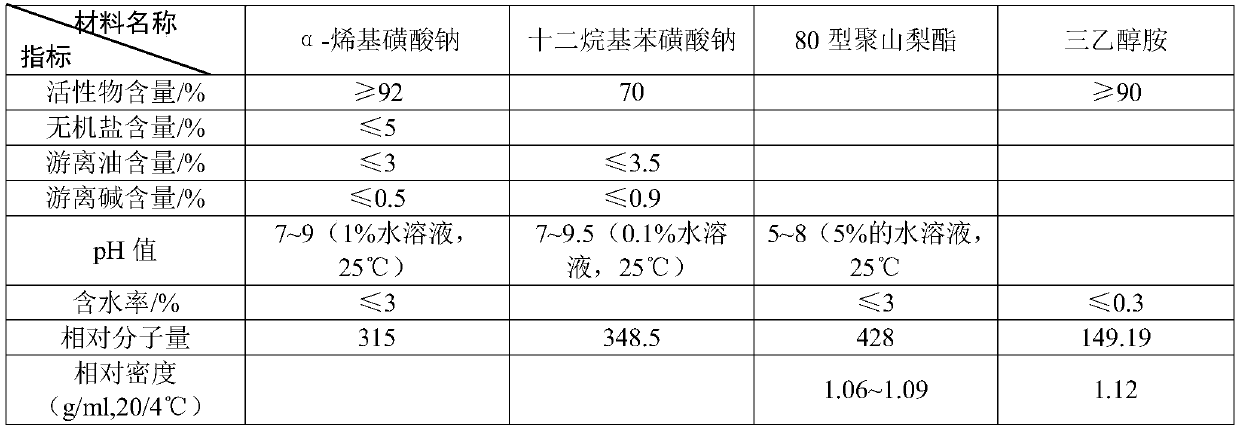

[0017] 1) Add sodium α-alkenyl sulfonate to water, stir until sodium α-alkenyl sulfonate is completely dissolved, and obtain A solution;

[0018] 2) Add polysorbate 80 and triethanolamine to solution A, and use a high-speed shearing machine to shear at a speed of 2000r / min until mixed evenly to obtain solution B;

[0019] 3) Add RA-2 rejuvenator to the B solution, and use a high-speed shearing machine to shear at a speed of 3000r / min until mixed evenly, and the obtained product is the base asphalt warm mix regenerant.

[0020] Further, the mass-number ratio of the water, sodium α-olefin sulfonate, polysorbate 80, triethanolamine and RA-2 regeneration agent is 26:5:9.4:15.2:44.4.

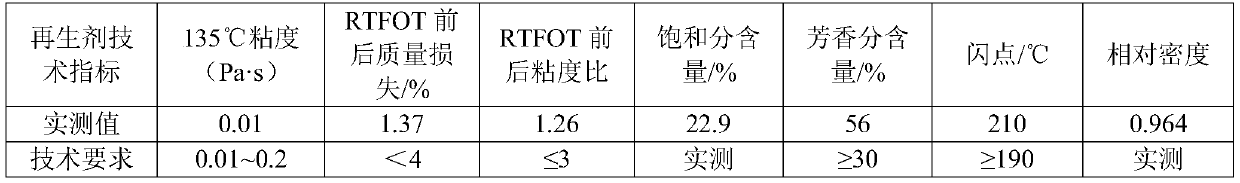

[0021] Further, make RA-2 regeneration agent as follows:

[0022] (1) Heat the extracted oil to 100-120°C, then add epoxy soybean oil and turpentine to the extracted oil, and stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com