Preparation method for xylooligosaccharide

A technology for xylo-oligosaccharide and sugarcane molasses, which is applied in the field of xylo-oligosaccharide production and can solve the problems of technical difficulty, excessive waste water, large environmental pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

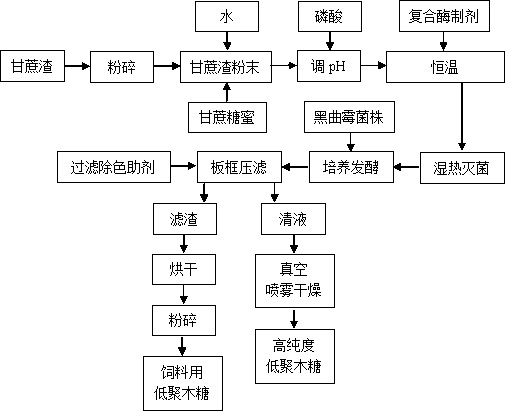

Method used

Image

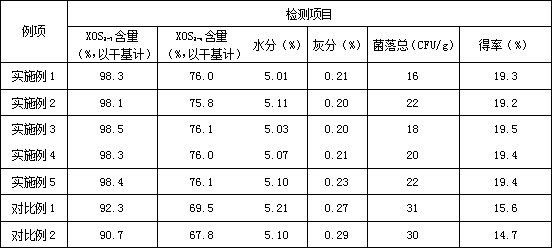

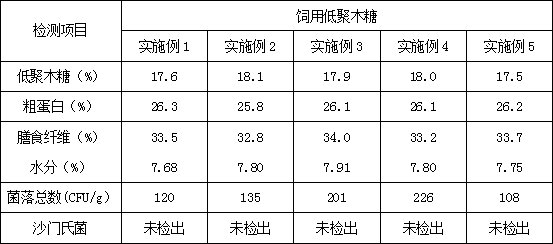

Examples

Embodiment 1

[0022] A preparation method of xylooligosaccharides, comprising the following steps:

[0023] (1) Crush bagasse into bagasse powder with a diameter of less than 0.5mm, weigh 100kg of bagasse powder, 800kg of water and 100kg of sugarcane molasses (total sugar content 46.7%, total number of colonies 37,000 CFU / g) and mix to obtain the first mixture ;

[0024] (2) Adjust the pH of the first mixture in step (1) to 4.50 with 0.2 kg of phosphoric acid, raise the temperature to 45°C, add 1 kg of compound enzyme preparation, and maintain this temperature for 2 hours, wherein the compound enzyme preparation consists of 20% β-glucanase, 25% pectinase, 35% acid cellulase and 20% acid protease are composed to obtain the second mixture;

[0025] (3) The second mixture of step (2) was sterilized by damp heat at 121°C for 20 minutes, cooled to 40°C after sterilization, 3 kg of Aspergillus niger strain was added, cultured and fermented at 40°C for 50 hours to obtain a fermentation liquid;

...

Embodiment 2

[0030] A preparation method of xylooligosaccharides, comprising the following steps:

[0031] (1) Crush bagasse into bagasse powder with a diameter of less than 0.5mm, weigh 100kg of bagasse powder, 800kg of water and 100kg of sugarcane molasses (total sugar content 45.1%, total number of colonies 33,000 CFU / g) and mix to obtain the first mixture ;

[0032] (2) Adjust the pH of the first mixture in step (1) to 4.60 with 0.2 kg of phosphoric acid, raise the temperature to 46°C, add 1 kg of compound enzyme preparation, and maintain this temperature for 4 hours, wherein the compound enzyme preparation consists of 25% Beta-glucanase, 30% pectinase, 25% acid cellulase and 20% acid protease are composed to obtain the second mixture;

[0033] (3) The second mixture of step (2) was sterilized by damp heat at 121°C for 30 minutes, cooled to 40°C after sterilization, 3 kg of Aspergillus niger strain was added, cultured and fermented at 45°C for 50 hours to obtain a fermentation liquid;...

Embodiment 3

[0038] A preparation method of xylooligosaccharides, comprising the following steps:

[0039] (1) Crush bagasse into bagasse powder with a diameter of less than 0.5mm, weigh 100kg of bagasse powder, 800kg of water and 100kg of sugarcane molasses (total sugar content 47.7%, total number of colonies 31,000 CFU / g) and mix to obtain the first mixture ;

[0040] (2) Adjust the pH of the first mixture in step (1) to 5.00 with 0.23 kg of phosphoric acid, raise the temperature to 55°C, add 1 kg of compound enzyme preparation, and maintain this temperature for 4 hours, wherein the compound enzyme preparation consists of 20% Beta-glucanase, 30% pectinase, 30% acid cellulase and 20% acid protease are composed to obtain the second mixture;

[0041] (3) The second mixture of step (2) was sterilized by damp heat at 121°C for 25 minutes, cooled to 40°C after sterilization, 3 kg of Aspergillus niger strain was added, cultured and fermented at 42°C for 50 hours to obtain a fermentation liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com