PDMS packaging technology-based microfluid metamaterial structure

A technology of microfluidics and metamaterials, applied in the direction of electrical components, antennas, etc., can solve problems such as difficult integration, thick absorber unit size, etc., to achieve the effect of ensuring accuracy, high dielectric constant, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

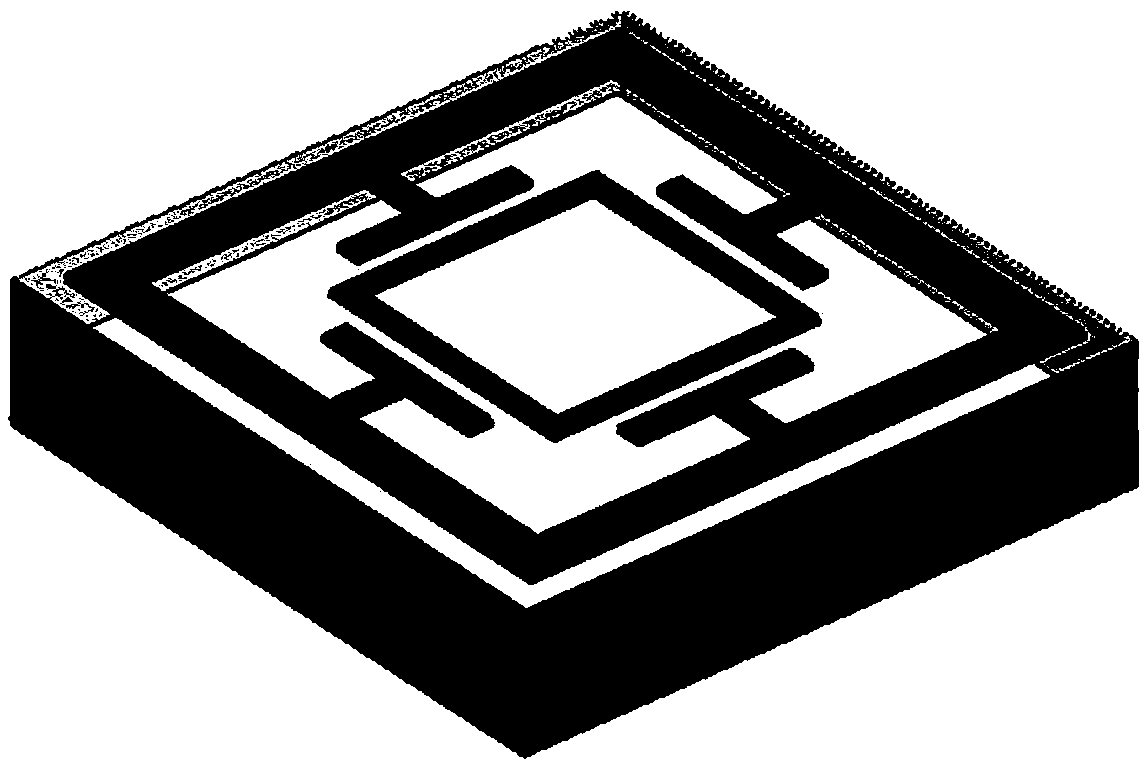

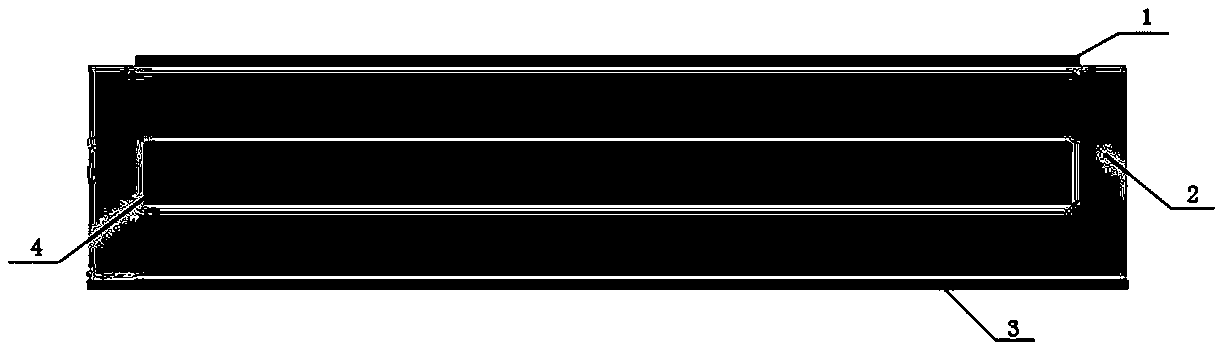

[0018] The design idea of the microfluidic metamaterial structure based on PDMS encapsulation technology includes the following steps:

[0019] Combined with the conventional "sandwich" absorbing structure, the original dielectric layer is replaced by a PDMS-encapsulated microfluidic structure. The production process of the PDMS encapsulation layer is: prepare the prepolymer and the curing agent at a mass ratio of 10:1 , the preparation solution was poured on the SU-8 mold, poured into the mold and stood in a vacuum box for 12 hours, then heated on the baking table from room temperature, heated at 75°C for 4 hours to completely solidify, and demolded to obtain the bottom layer of PDMS; Prepare the prepolymer and curing agent according to the mass ratio of 15:1, stir evenly, and defoam; secondly, spin-coat the prepared solution on the silicon wafer, and heat it at 70°C for 20 minutes to partially cure it, and obtain PDMS cover sheet: Plasma treatment is performed on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com