Preparation method of titanium base biomedical gradient composite material

A composite material and biomedical technology, which is applied in the field of preparation of titanium-based biomedical gradient composite materials, can solve the problems of cytotoxic reaction nerve and physiological disorder, stress-shielding, implant loosening, etc., and achieves short sintering time and good quality. Interfacial bonding, the effect of lowering the elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a titanium-based biomedical graded composite material, specifically comprising the following steps:

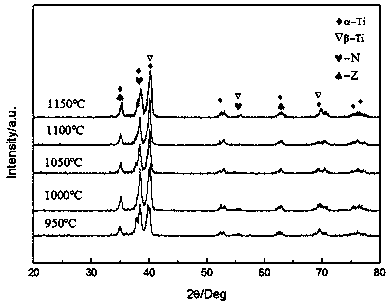

[0023] (1) Weigh the Ti, Nb and Zr powders with a particle size of 75 μm according to the mass percentage of Nb: 15%, Zr: 15%, Ti: 70%, and use a ball-to-material ratio of 5:1 and 200r / min Mix the powder by speed ball milling for 5 hours to obtain figure 1 The TiNbZr mixed powder shown.

[0024] (2) Ti powder with a particle size of 150 μm and NH with a particle size of 500 μm 4 HCO 3 The powder is mixed to obtain Ti-NH 4 HCO 3 Mixed powder, in mixed powder Ti-NH 4 HCO 3 The mass percentage of Ti powder in the medium is 70%, NH 4 HCO 3 The mass percentage of powder is 30%.

[0025] (3) Ti-NH to be obtained 4 HCO 3 The mixed powder and TiNbZr alloy mixed powder are respectively filled into the outer layer and inner layer of the sleeve with the annular partition, and after the partition is taken out, the pressure testing machine is used ...

Embodiment 2

[0032] A preparation method of a titanium-based biomedical graded composite material, specifically comprising the following steps:

[0033] (1) Weigh the Ti, Nb and Zr powders with a particle size of 23 μm according to the mass percentage of Nb: 10%, Zr: 20%, Ti: 70%, and use the ball-to-material ratio of 3:1 and 400r / min Speed ball milling mixed powder for 2 hours to obtain TiNbZr mixed powder.

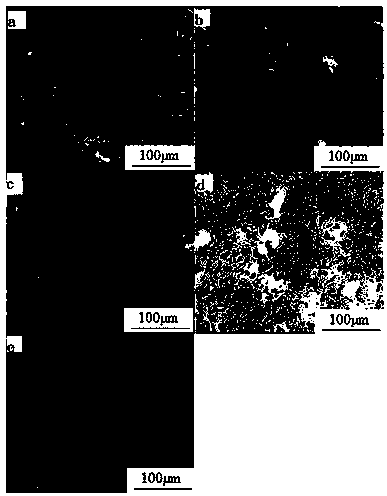

[0034](2) Ti powder with a particle size of 23 μm and NH with a particle size of 300 μm 4 HCO 3 The powder is mixed to obtain Ti-NH 4 HCO 3 Mixed powder, in mixed powder Ti-NH 4 HCO 3 Middle NH 4 HCO 3 The mass percent of powder is 5wt.%, 15wt.% and 30wt.%.

[0035] (3) Then the obtained TiNbZr mixed powder and Ti-NH 4 HCO 3 The mixed powder is filled into the inner and outer layers of the mold sleeve, and pressed on a pressure testing machine with a pressure of 50 MPa; finally, the pressed green body is put into a graphite mold, and sintered on a spark plasma sintering e...

Embodiment 3

[0039] A preparation method of a titanium-based biomedical graded composite material, specifically comprising the following steps:

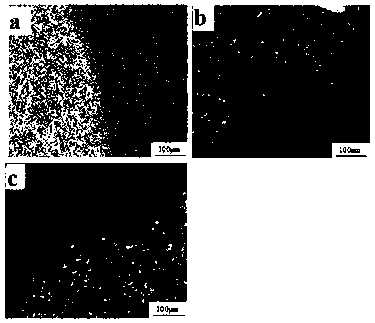

[0040] (1) Weigh the Ti, Nb, Zr powders with purity of 99.5%, 99.95% and 99.95% respectively, and particle size of 70 μm, according to mass percentage (wt%) 70%: 20%: 10% ratio; then put into ball mill Ball milling was carried out at 600r / min in the tank. During the ball milling process, the ball milling medium is stainless steel balls with a ball-to-material ratio of 1:1, sealed with alcohol and then vacuumed to 20Pa, then ball milled for 10 hours, and the obtained metal mixed powder is dried.

[0041] (2) Ti powder with a particle size of 70 μm and NH with a particle size of 100 μm 4 HCO 3 The powder is mixed to obtain Ti-NH 4 HCO 3 Mixed powder, in mixed powder Ti-NH 4 HCO 3 The mass percentage of Ti powder in the medium is 80%, NH 4 HCO 3 The mass percent of the powder is 20%; the obtained Ti-NH 4 HCO 3 The mixed powder and TiNbZr a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com