Preparation method of efficient biofilm forming material, and preparation method of biofilm forming filler

A bio-filming, high-efficiency technology, applied in separation methods, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem that the microbial domestication period cannot be reduced, the activity of intracellular proteins cannot be effectively stimulated, and far-infrared rays cannot be generated to stimulate microbial metabolic activity and other issues, to achieve the effect of high mechanical strength and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A kind of preparation method of high-efficiency bio-film-hanging material provided by the invention comprises the following steps:

[0053] Step 1: Shape processing of weakly magnetic porous materials

[0054] Remove the surface edges and corners of the weakly magnetic porous material with a particle size of 30-50mm, high rare earth content, and a surface magnetic field strength of 0.11-60mT, and then use a fan to blow off the dust on the surface before use;

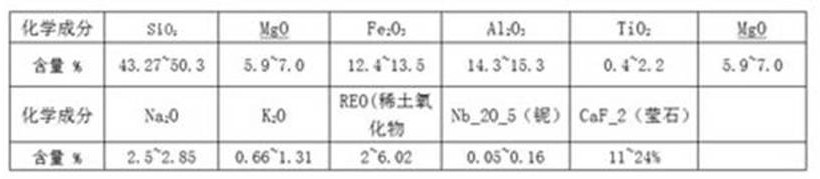

[0055] The composition list of the weakly magnetic porous material is as follows:

[0056]

[0057] Step 2: Preparation of Surface Modifier for Weakly Magnetic Porous Materials

[0058] Fe2O3, Fe 3 + and potassium hydroxide, in OH - According to the molar ratio of 1:3, add it to 3.5-4.5 cubic meters of water, mix and stir evenly, and let it stand for 36h-48h under the condition of 30-50 degrees, and set aside; among them, the total amount of ferric oxide and potassium hydroxide The weight is 95~105Kg;

[005...

Embodiment 1

[0074] Embodiment 1, a kind of preparation method of high-efficiency biological film hanging material, comprises the following steps:

[0075] Step 1: Shape processing of weakly magnetic porous materials

[0076] 1. The selected production areas are Baiyun Obo in Inner Mongolia, southern Jiangxi, northern Yuebei in Guangdong, Liangshan in Sichuan, Weishan in Shandong, Fujian and other places. The content of rare earths formed by volcanic eruptions is relatively high, and they have strong magnetic properties and low far-infrared characteristics. Weakly magnetic porous material, commonly known as biological hanging film material.

[0077] The composition of the weak magnetic porous material is as follows:

[0078]

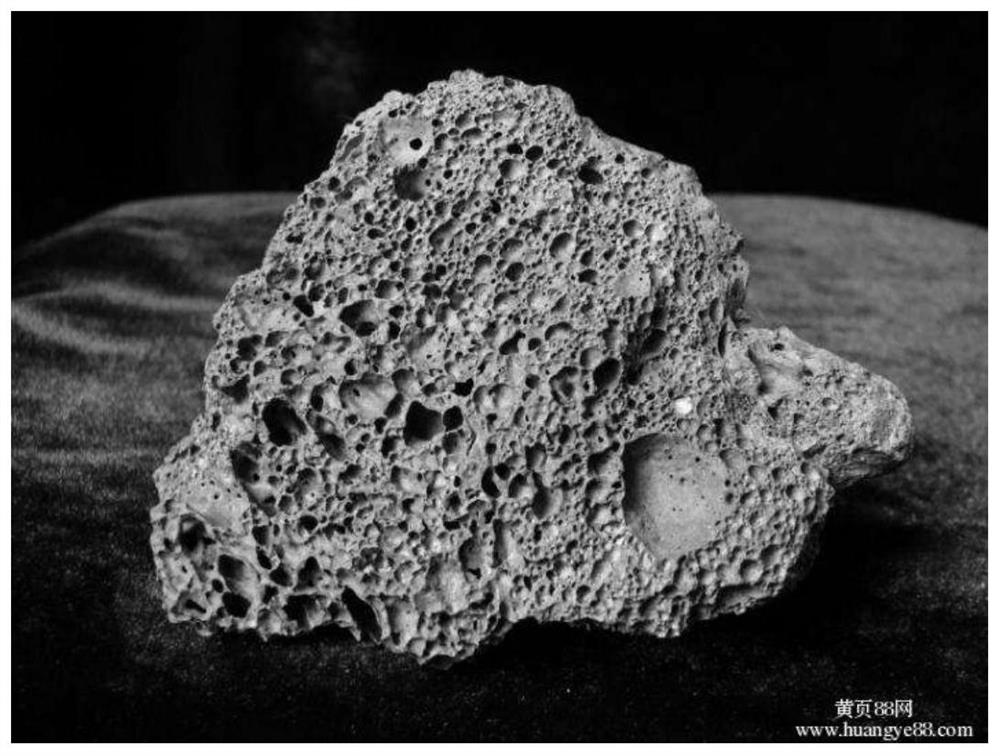

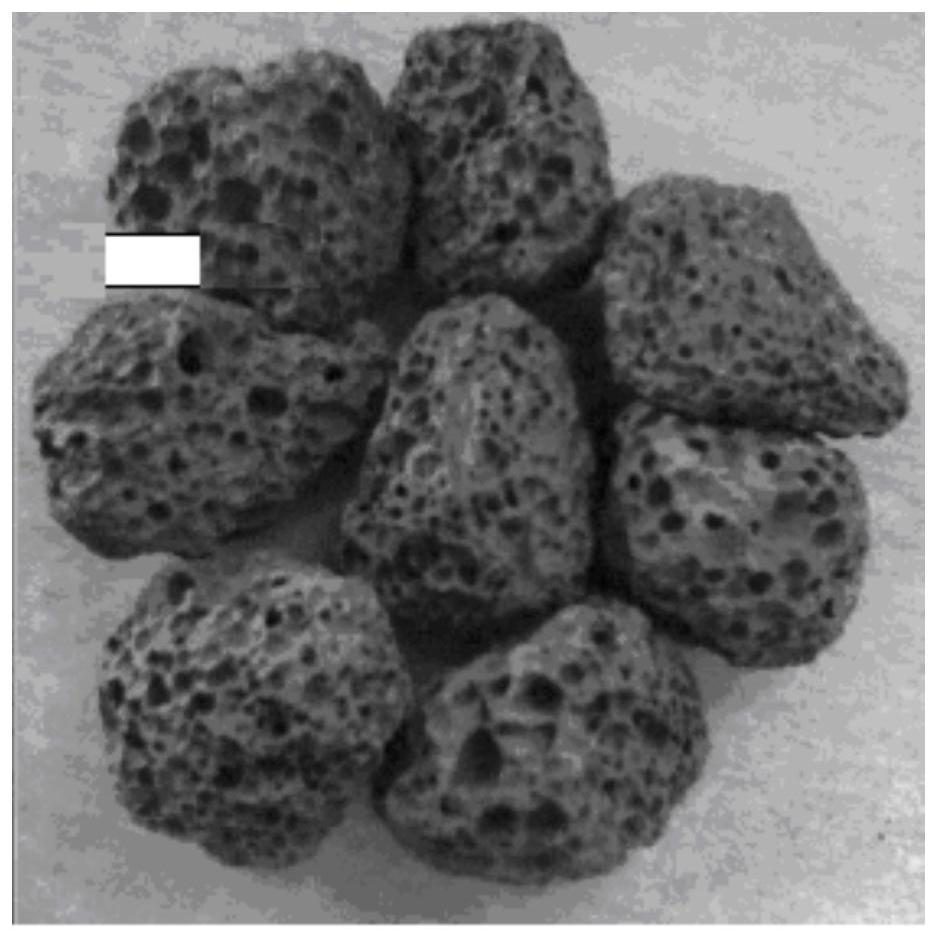

[0079] 2. Select a weakly magnetic porous material with a particle size of 40 mm, such as figure 1 .

[0080] 3. Put the block-shaped weakly magnetic porous material into the blender, the filling amount is 50% of the maximum filling amount of the blender, turn ...

Embodiment 2

[0095] Embodiment 2, a kind of preparation method of high-efficiency biofilm-hanging material, comprises the following steps:

[0096] Step 1: Shape processing of weakly magnetic porous materials

[0097] 1. The selected production areas are Baiyun Obo in Inner Mongolia, southern Jiangxi, northern Yuebei in Guangdong, Liangshan in Sichuan, Weishan in Shandong, Fujian and other places. The content of rare earths formed by volcanic eruptions is relatively high, and they have strong magnetic properties and low far-infrared characteristics. Weakly magnetic porous material, commonly known as biological hanging film material.

[0098] The composition of the weak magnetic porous material is as follows:

[0099]

[0100] 2. Select a weakly magnetic porous material with a particle size of 50 mm, such as figure 1 .

[0101] 3. Put the block-shaped weakly magnetic porous material into the blender, the filling amount is 30% of the maximum filling amount of the blender, turn on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com