Method for improving polyurethane foam oil absorbency

A polyurethane foam and performance technology, applied in the field of green preparation of oil-absorbing materials, can solve the problems of low recycling times, low monomer grafting rate, and low oil absorption ratio, and achieve low production costs, high grafting rates, and cycle adsorption times high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

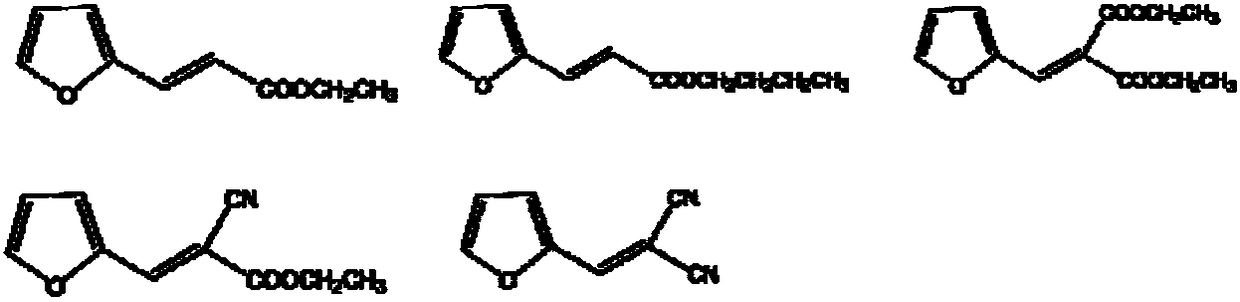

Method used

Image

Examples

Embodiment 1

[0011] Add 0.6g of polyurethane foam with a density of 35kg / m3, 0.03g of benzoyl peroxide, and 0.3g of lauryl methacrylate into the autoclave, pump in carbon dioxide with a supercritical fluid pump, and heat up to 75 o C, the pressure is 8Mpa, the stirring speed is 100r / min, the reaction is 6h, the pressure is released and the temperature is lowered, and the product is taken out and washed 2 times with ethanol and deionized water, at 70 o Dry at C to obtain an oil-absorbing material.

Embodiment 2

[0013] 0.6g of polyurethane foam with a density of 35kg / m3, 0.03g of benzoyl peroxide, 0.3g of lauryl methacrylate, and 0.1g of styrene were added to the autoclave, and carbon dioxide was pumped in with a supercritical fluid pump, and the temperature was raised to 75 o C, the pressure is 8Mpa, the stirring speed is 100r / min, the reaction is 6h, the pressure is released and the temperature is lowered, and the product is taken out and washed 2 times with ethanol and deionized water, at 70 o Dry at C to obtain an oil-absorbing material.

Embodiment 3

[0015] 0.6g of polyurethane foam with a density of 35kg / m3, 0.03g of benzoyl peroxide, 0.3g of lauryl methacrylate, and 0.3g of styrene were added to the autoclave, and carbon dioxide was pumped in with a supercritical fluid pump, and the temperature was raised to 75 o C, the pressure is 8Mpa, the stirring speed is 100r / min, the reaction is 6h, the pressure is released and the temperature is lowered, and the product is taken out and washed 2 times with ethanol and deionized water, at 70 o Dry at C to obtain an oil-absorbing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com