Production process of calcium levofolinate lyophilized powder for injection

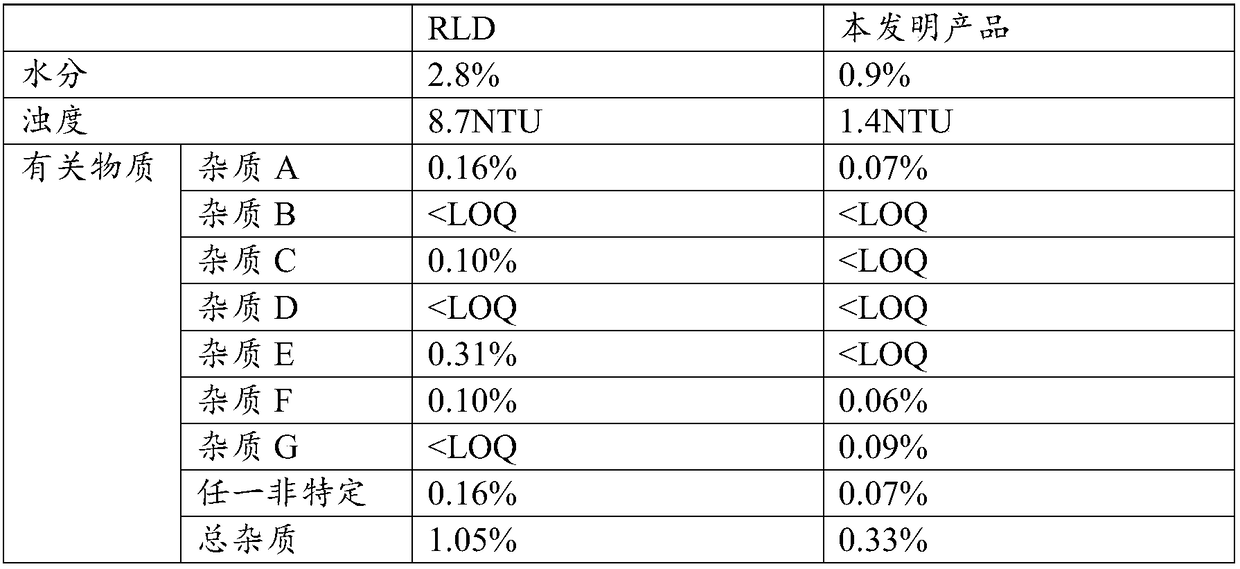

A technology of calcium levofolinate and freeze-dried powder injection, applied in the field of medicine, can solve the problems of re-contaminated product content, low content of medicinal liquid, difficult to control, etc., and achieves shortening of liquid dispensing process time, low moisture content, and favorable safety. and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A production process of calcium levofolinate freeze-dried powder for injection, comprising the following steps:

[0032] (1) Add water for injection at 40°C in the liquid mixing tank;

[0033] (2) By mass, add 1 part of mannitol and stir until dissolved, keeping the liquid temperature at 40°C;

[0034] (3) Add 1 part of calcium levofolinate raw material and stir until dissolved, lower the temperature of the liquid medicine to 20°C, adjust the pH to 7.8, add water for injection to dilute to 1000 parts;

[0035] (4) After sterilizing and filtering, filling and freeze-drying, the preparation product is obtained.

Embodiment 2

[0037] A production process of calcium levofolinate freeze-dried powder for injection, comprising the following steps:

[0038] (1) Add water for injection at 50°C in the liquid distribution tank;

[0039] (2) By mass, add 1 part of mannitol and stir until dissolved, keeping the liquid temperature at 50°C;

[0040] (3) Add 1 part of calcium levofolinate raw material and stir until dissolved, lower the temperature of the liquid medicine to 30°C, adjust the pH to 8.2, add water for injection to dilute to 1000 parts;

[0041] (4) After sterilizing and filtering, filling and freeze-drying, the preparation product is obtained.

[0042] The endotoxin of the bulk drug is less than 0.500 EU / mg, and the endotoxin of mannitol is less than 2.5 EU / g.

[0043] Described (3) step adopts 0.05mol / L sodium hydroxide solution to adjust the pH value.

Embodiment 3

[0045] A production process of calcium levofolinate freeze-dried powder for injection, comprising the following steps:

[0046] (1) Add 90% of the demanded water for injection at 45°C in the liquid distribution tank;

[0047] (2) By mass, add 1 part of mannitol and stir until dissolved, keeping the liquid temperature at 45°C;

[0048] (3) Add 1 part of calcium levofolinate raw material and stir until dissolved, lower the temperature of the liquid medicine to 25°C, adjust the pH to 8.0, add the remaining demanded amount of water for injection and set the volume to 1000 parts;

[0049] (4) After sterilizing and filtering, filling and freeze-drying, the preparation product is obtained.

[0050] The endotoxin of the bulk drug is less than 0.500 EU / mg, and the endotoxin of mannitol is less than 2.5 EU / g.

[0051] Described (3) step adopts 0.05mol / L hydrochloric acid solution to adjust pH value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com