Application of metal ion complexing agent in waste and old lithium iron phosphate battery recovery process

A technology of lithium iron phosphate battery and waste lithium battery, which is applied in the direction of waste collector recycling, lithium carbonate;/acid carbonate, etc., can solve the problems of low purity, limited reuse, etc., and achieves simple process operation, The effect of cost controllable and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

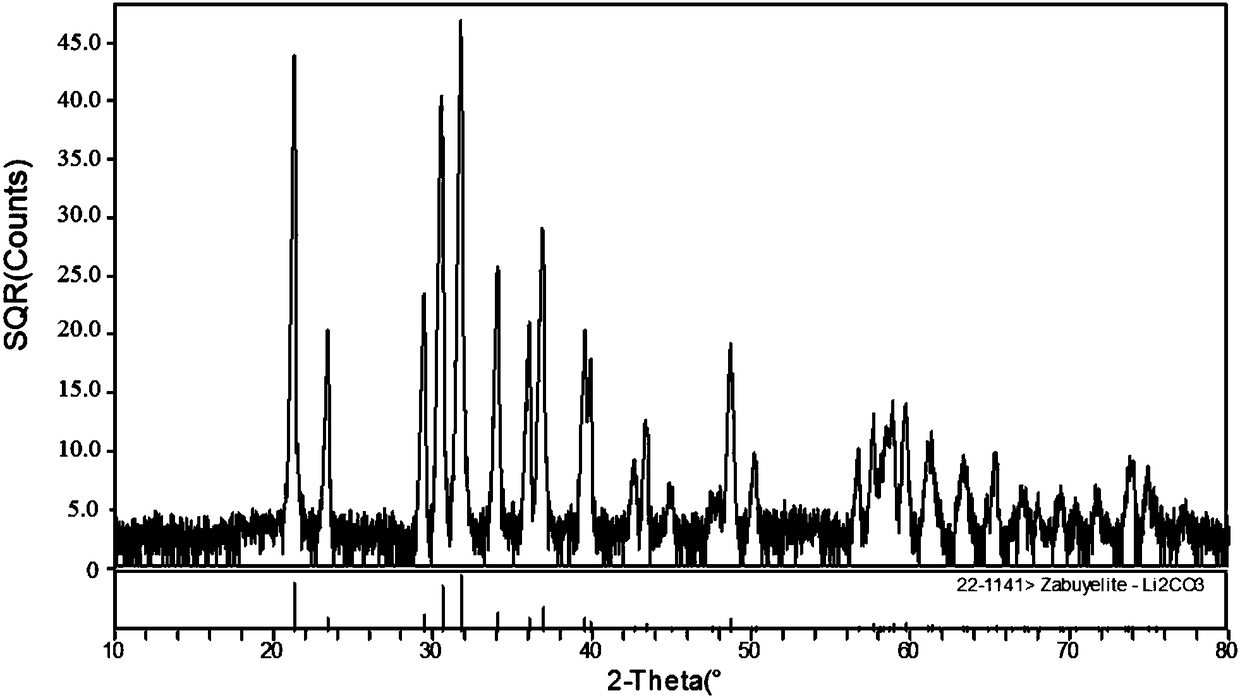

Embodiment 1

[0041] This embodiment provides a method for recycling waste lithium iron phosphate batteries, comprising the following steps:

[0042] S101: LiFePO will be scrapped 4 After the battery is discharged, mechanically disassembled and stripped, ultrasonically dispersed, and sieved, the black powder mixed with graphite powder and lithium iron phosphate is obtained.

[0043] S102: Dissolve 50 g of the above black powder in 125 mL of 2mol / L hydrochloric acid and 15 mL of 30% H 2 o 2 In the compound solution, heat and stir at 80°C for 2h, cool and stand still, and filter to obtain the filtrate containing Li and Fe and graphite powder.

[0044] S103: Add 50mL of 1000ppm Fe(NO 3 ) 3 Solution, and by adding NaOH solution to adjust the pH value of the system to 4, to obtain phosphate precipitate and filtrate.

[0045] S104: Add lye to the filtrate obtained in S103 to adjust the pH value to 10, and then remove the residual metal ion complexing agent to obtain a Li-containing + enrich...

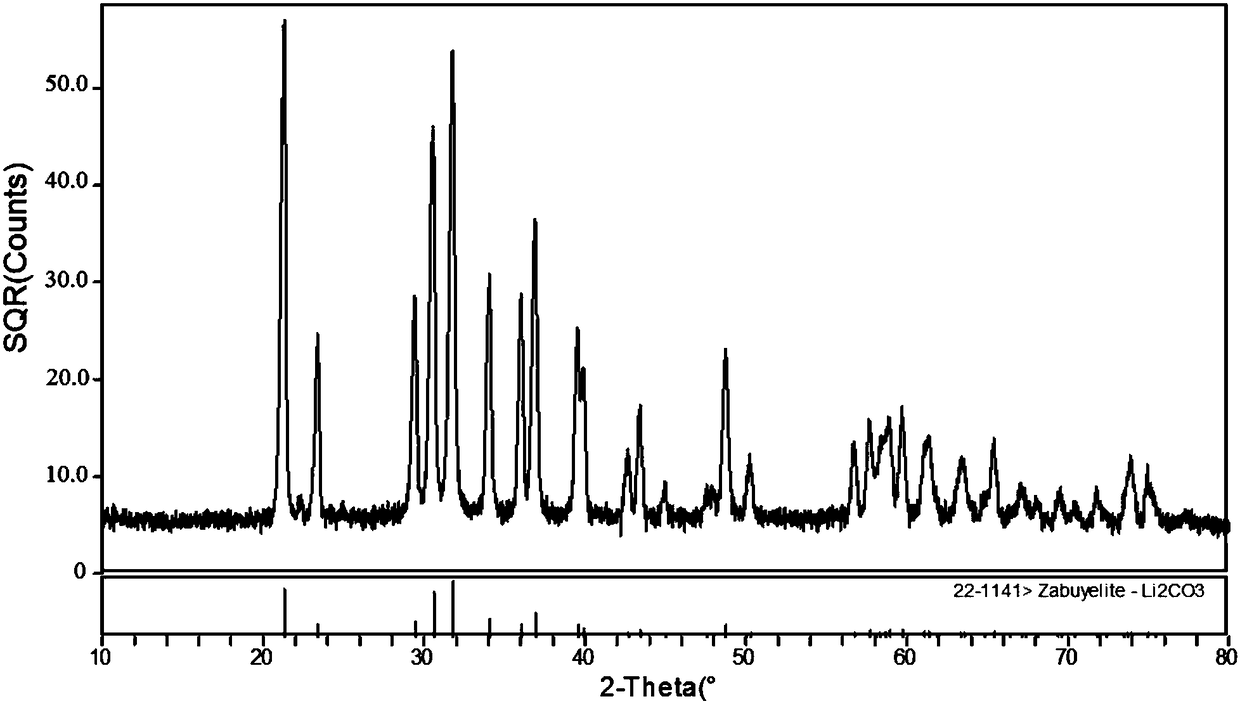

Embodiment 2

[0049] This embodiment provides a method for recycling waste lithium iron phosphate batteries, comprising the following steps:

[0050] S101: LiFePO will be scrapped 4 After the battery is discharged, mechanically disassembled and stripped, ultrasonically dispersed, and sieved, the black powder mixed with graphite powder and lithium iron phosphate is obtained.

[0051] S102: Dissolve 100g of the above black powder in 250mL of 2mol / L HNO 3 solution with 30mL of 30% H 2 o 2 In the compound solution, heat and stir at 75°C for 3h, cool and stand still, and filter to obtain the filtrate containing Li and Fe and graphite powder.

[0052] S103: Add 80mL of 1000ppm Fe to the filtrate containing Li and Fe 2 (SO 4 ) 3 Solution, and by adding NaOH solution to adjust the pH value of the system to 3, to obtain phosphate precipitate and filtrate.

[0053] S104: Add lye to the filtrate obtained in S103 to adjust the pH value to 12, and then remove the residual metal ion complexing age...

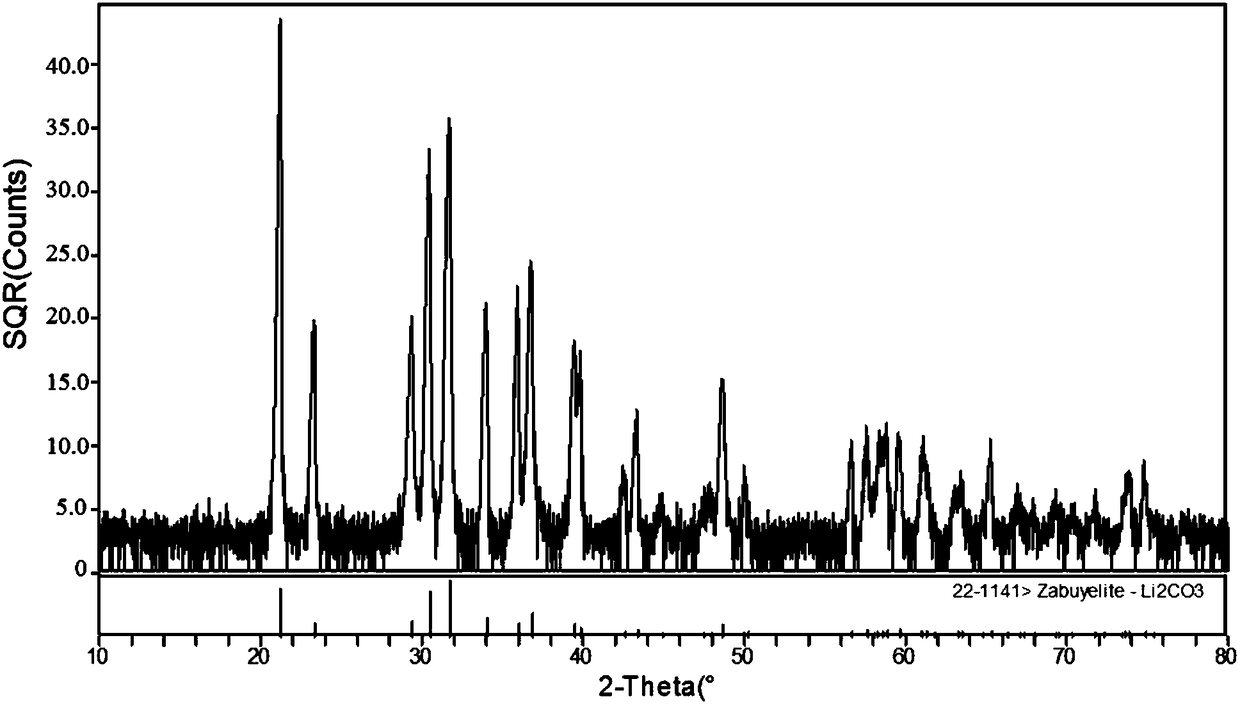

Embodiment 3

[0058] This embodiment provides a method for recycling waste lithium iron phosphate batteries, comprising the following steps:

[0059] S101: LiFePO will be scrapped 4 After the battery is discharged, mechanically disassembled and stripped, ultrasonically dispersed, and sieved, the black powder mixed with graphite powder and lithium iron phosphate is obtained.

[0060] S102: Dissolve 100g of the above black powder in 250mL of 2mol / L H 2 SO 4 solution with 30mL of 30% H 2 o 2 In the compound solution, heat and stir at 80°C for 5h, cool and stand still, and filter to obtain the filtrate containing Li and Fe and graphite powder.

[0061] S103: Add 100mL of 1000ppm Fe(NO 3 ) 3 Solution, and by adding NaOH solution to adjust the pH value of the system to 2, to obtain phosphate precipitate and filtrate.

[0062] S104: Add lye to the filtrate obtained in S103 to adjust the pH value to 9, and then remove the residual metal ion complexing agent to obtain a Li-containing + enric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com