A thermal insulation plastering slurry and its application method

A kind of mortar material and formula technology, applied in the field of thermal insulation plastering slurry, can solve the problems of workability, insufficient operability, difficulty in removing the insulation layer, slow construction process, etc., and achieve the purpose of prolonging the initial setting time, partial demolition and Restoring effects that are easy to implement and have ample construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

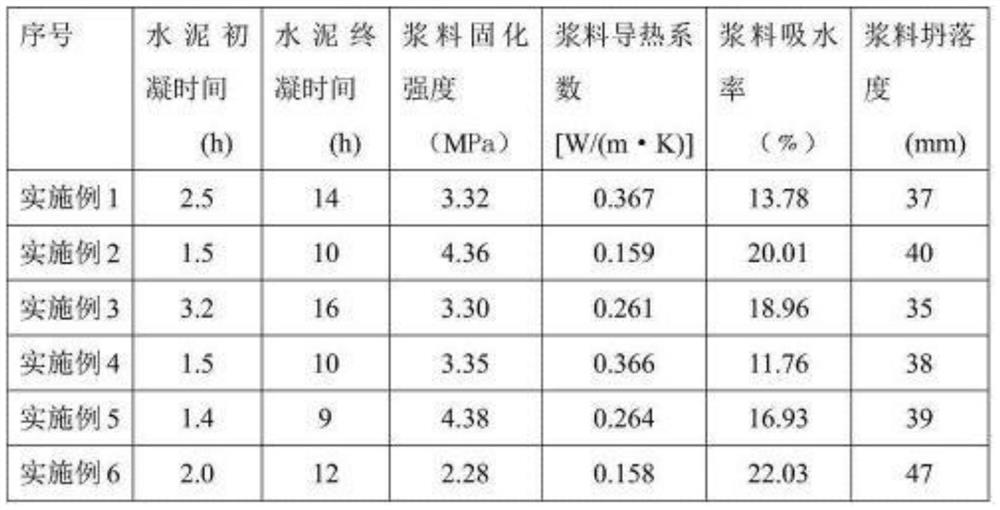

Examples

Embodiment 1

[0018] A thermal insulation plastering slurry is prepared from the following raw materials in parts by weight: 10 parts of aluminate cement, 30 parts of clay refractory mud, 10 parts of asbestos wool, 3 parts of perlite and 10 parts of water. How to use this thermal insulation plastering paste:

[0019] 1) Stir the clay refractory mud and aluminate cement in the formula amount first, then add perlite and stir evenly, finally add asbestos wool and stir evenly, then slowly add water, and stir evenly;

[0020] 2) use The pins are made of galvanized iron wire or carbon round steel. The pins are straight or L-shaped, and are directly welded on the equipment and pipes. The length of the straight section of the pin is 50-80 mm longer than the insulation layer, and the spacing is not greater than 350 mm. 6-8 per square meter; Pave the insulation layer, the thickness meets the requirements;

[0021] 3) use Galvanized wire mesh or stainless steel wire mesh is bundled on the surface...

Embodiment 2

[0024] A thermal insulation plastering slurry is prepared from the following raw materials in parts by weight: 30 parts of aluminate cement, 60 parts of clay refractory mud, 30 parts of asbestos wool, 8 parts of perlite and 30 parts of water.

[0025] How to use this thermal insulation plastering paste:

[0026] 1) Stir the clay refractory mud and aluminate cement in the formula amount first, then add perlite and stir evenly, finally add asbestos wool and stir evenly, then slowly add water, and stir evenly;

[0027] 2) use The pins are made of galvanized iron wire or carbon round steel. The pins are straight or L-shaped, and are directly welded on the equipment and pipes. The length of the straight section of the pin is 50-80 mm longer than the insulation layer, and the spacing is not greater than 350 mm. 6-8 per square meter; Pave the insulation layer, the thickness meets the requirements;

[0028] 3) use Galvanized wire mesh or stainless steel wire mesh is bundled on th...

Embodiment 3

[0031] A thermal insulation plastering slurry is prepared from the following raw materials in parts by weight: 10 parts of aluminate cement, 40 parts of clay refractory mud, 20 parts of asbestos wool, 4 parts of perlite and 15 parts of water.

[0032] How to use this thermal insulation plastering paste:

[0033] 1) Stir the clay refractory mud and aluminate cement in the formula amount first, then add perlite and stir evenly, finally add asbestos wool and stir evenly, then slowly add water, and stir evenly;

[0034] 2) use The pins are made of galvanized iron wire or carbon round steel. The pins are straight or L-shaped, and are directly welded on the equipment and pipes. The length of the straight section of the pin is 50-80 mm longer than the insulation layer, and the spacing is not greater than 350 mm. 6-8 per square meter; Pave the insulation layer, the thickness meets the requirements;

[0035] 3) use Galvanized wire mesh or stainless steel wire mesh is bundled on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com