Scrap steel preheating device through horizontal continuous charging electric-arc furnace and using method

A preheating device, electric arc furnace technology, applied in the direction of electric furnace, furnace, furnace type, etc., can solve the problems of limited preheating temperature of scrap steel, lower flue gas temperature, harmful gas generation, etc., achieve good results, speed up production rhythm, The effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

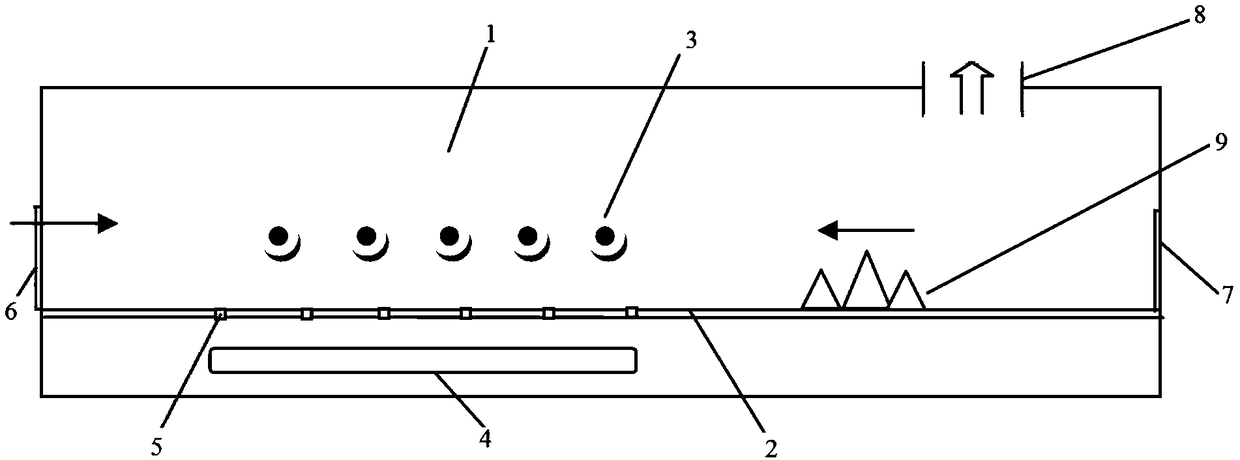

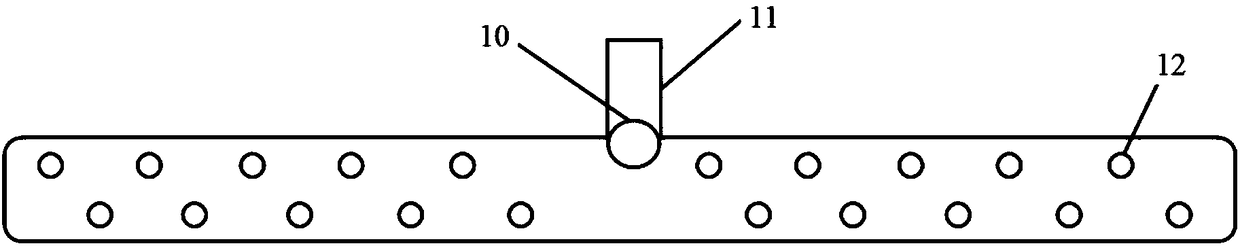

[0044] A horizontal continuous feeding electric arc furnace scrap steel preheating device, including a preheating section body, a gas transmission and exhaust system, the gas transmission and exhaust system includes gas transmission equipment and an exhaust port, such as figure 1 As shown, the preheating section body 1 is provided with a conveying roller table 2, an igniter 3, a gas transmission device 4, and an exhaust port. The conveying roller table 2 is arranged under the preheating section body 1. There is a certain distance between the inner bottom of the section body 1, so that the distance between the conveying roller table and the inner bottom of the preheating section body forms a cavity, and the conveying roller table conveys raw materials into the electric arc furnace from right to left. The gas transmission equipment 4 is arranged in the cavity, and the gas transmission equipment 4 mainly provides combustion-supporting gas for the upper part of the transport roller...

Embodiment 2

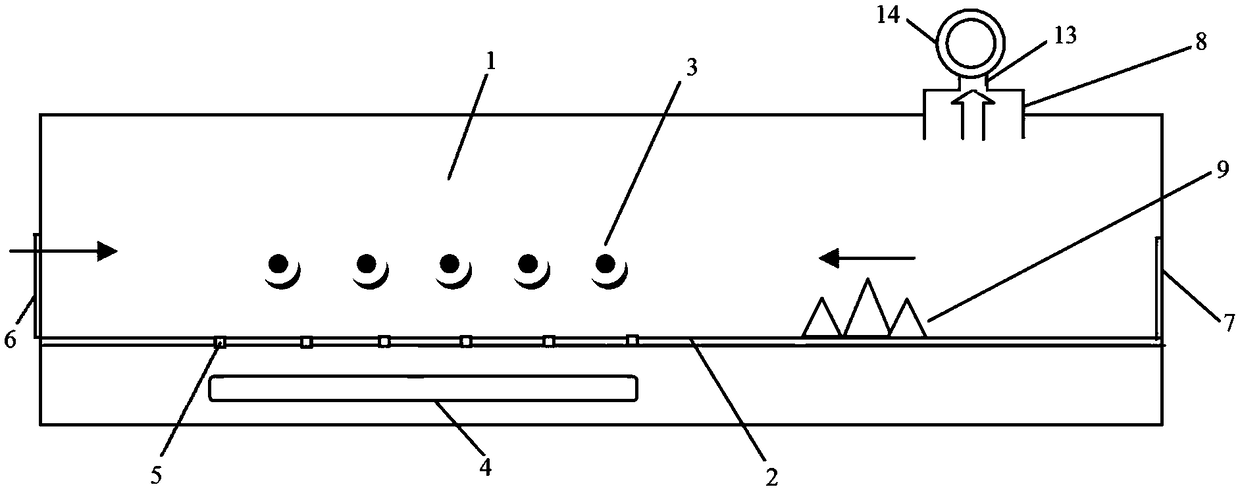

[0049] This embodiment is based on Embodiment 1. In order to quickly and effectively remove the smoke and combustion gas, a discharge device is installed on the exhaust port, such as image 3 As shown, the exhaust equipment includes an air extractor 14 and an exhaust duct 13, the exhaust duct 13 is connected to the exhaust port 8, and the air extractor 14 is connected to the exhaust duct 13, and the exhaust duct can be arranged on the body of the preheating section On the outside, through the exhaust machine, the smoke and combustion gas can be quickly discharged without affecting the preheating of scrap steel and other raw materials.

[0050] The method for using the above-mentioned horizontal continuous feeding electric arc furnace scrap steel preheating device includes the following steps:

[0051] Step 1, mixing steel scrap, coal, lime and other raw materials into a mixture, adding it to the transport roller table 2 of the horizontal continuous feeding electric arc furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com