Longitudinal deformed section steel plate and production method

A special-shaped section, steel plate technology, applied in the direction of sheet/plate, building components, metal rolling, etc., can solve the problems of low production efficiency, poor control stability, etc., to achieve high qualification rate, strong applicability, strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

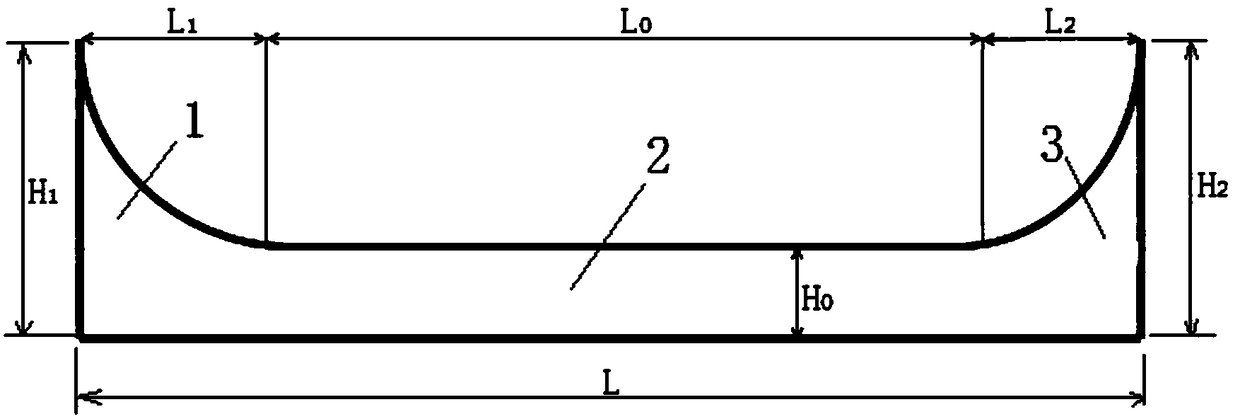

[0046] A 5500mm medium and thick plate rolling mill is used to roll a steel plate with a longitudinal special-shaped section of Q345B, and its longitudinal section shape is as follows figure 1 As shown, the specific dimensions are:

[0047] h 0 = 8mm, H 1 = 40mm, H 2 = 50mm, the total length of the steel plate L = 50000mm, of which the length of the gradual change section - 1 is L 1 =8000mm, length L of gradient section 2 3 2 =8500mm.

[0048] In the present embodiment, the production method of the longitudinal special-shaped section steel plate is as follows:

[0049] 1) Steel billet heating process: the steel billet heating temperature range is controlled at 1120-1150 °C, and the upper surface temperature is 30 °C higher than the lower surface temperature;

[0050] 2) After the billet is out of the furnace, it is descaled by high-pressure water with a pressure ≥ 20MPa;

[0051] 3) Rolling process: the starting rolling temperature is controlled at 1020°C, and the final...

Embodiment 2

[0056] A 5500mm medium and thick plate rolling mill is used to roll a steel plate with a longitudinal special-shaped section of Q345B, and its longitudinal section shape is as follows figure 1 As shown, the specific dimensions are:

[0057] h 0 =120mm,H 1 =150mm,H 2 =150mm, the total length of the steel plate L=12000mm, of which the length of the transition section-1 is L 1 =2500mm, length L of gradient section 2 3 2 =2500mm.

[0058] In the present embodiment, the production method of the longitudinal special-shaped section steel plate is as follows:

[0059] 1) Steel billet heating process: the steel billet heating temperature range is controlled at 1130-1170°C, and the upper surface temperature is 30°C higher than the lower surface temperature;

[0060] 2) After the billet is out of the furnace, it is descaled by high-pressure water with a pressure ≥ 20MPa;

[0061] 3) Rolling process: the starting rolling temperature is controlled at 1030°C, and the final rolling te...

Embodiment 3

[0066] A 5500mm medium and thick plate rolling mill is used to roll a steel plate with a longitudinal special-shaped section of Q345B, and its longitudinal section shape is as follows figure 1 As shown, the specific dimensions are:

[0067] h 0 =52mm,H 1 =72mm,H 2 = 80mm, the total length of the steel plate L = 20000mm, of which the length of the transition section - 1 is L 1 =3000mm, length L of gradient section 2 3 2 = 3500mm.

[0068] In the present embodiment, the production method of the longitudinal special-shaped section steel plate is as follows:

[0069] 1) Steel billet heating process: the steel billet heating temperature range is controlled at 1130-1150 °C, and the upper surface temperature is 30 °C higher than the lower surface temperature;

[0070] 2) After the billet is out of the furnace, it is descaled by high-pressure water with a pressure ≥ 20MPa;

[0071] 3) Rolling process: the starting rolling temperature is controlled at 1040°C, and the final rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com