Binder, composition, electrode material and preparation method thereof

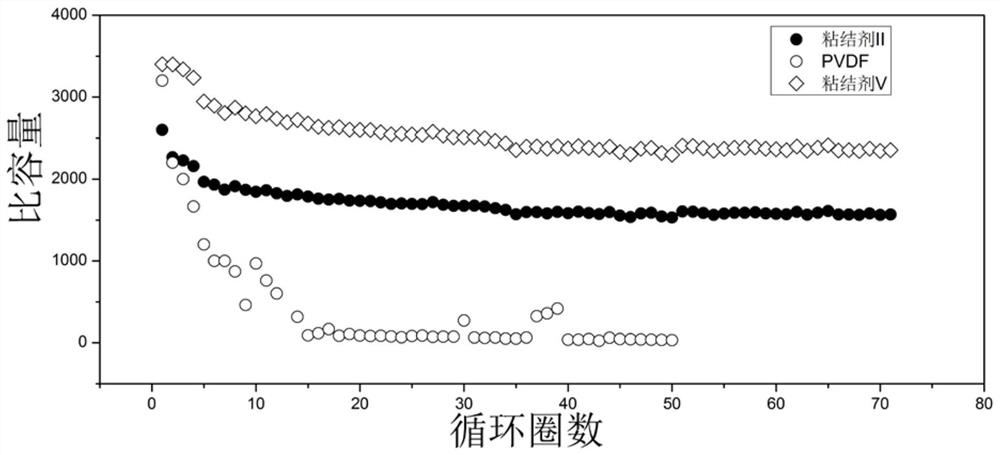

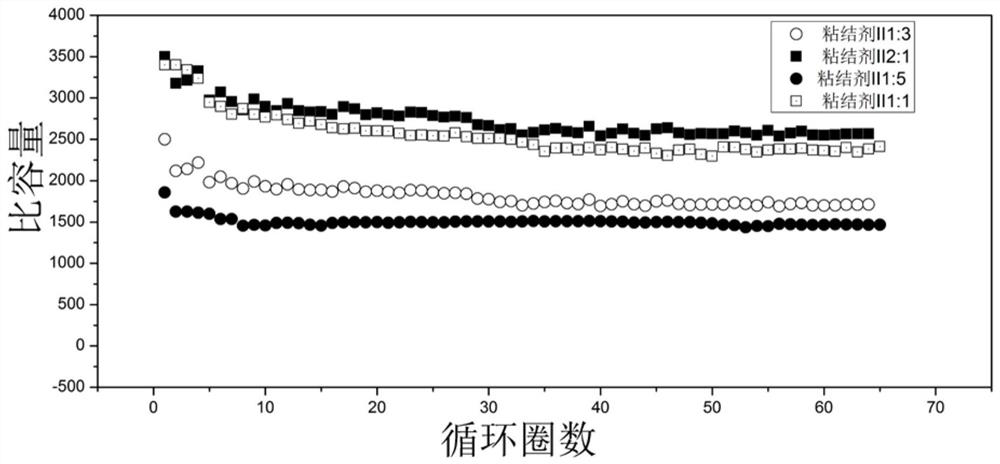

A technology of binder and composition, applied in the field of batteries, can solve the problems of inability to ensure the stability of electrode structure and shedding of active materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a kind of preparation method of described electrochemical cell electrode material, comprising:

[0057] S1, providing the composition and solvent;

[0058] S2, mixing the composition and the solvent to obtain a mixture;

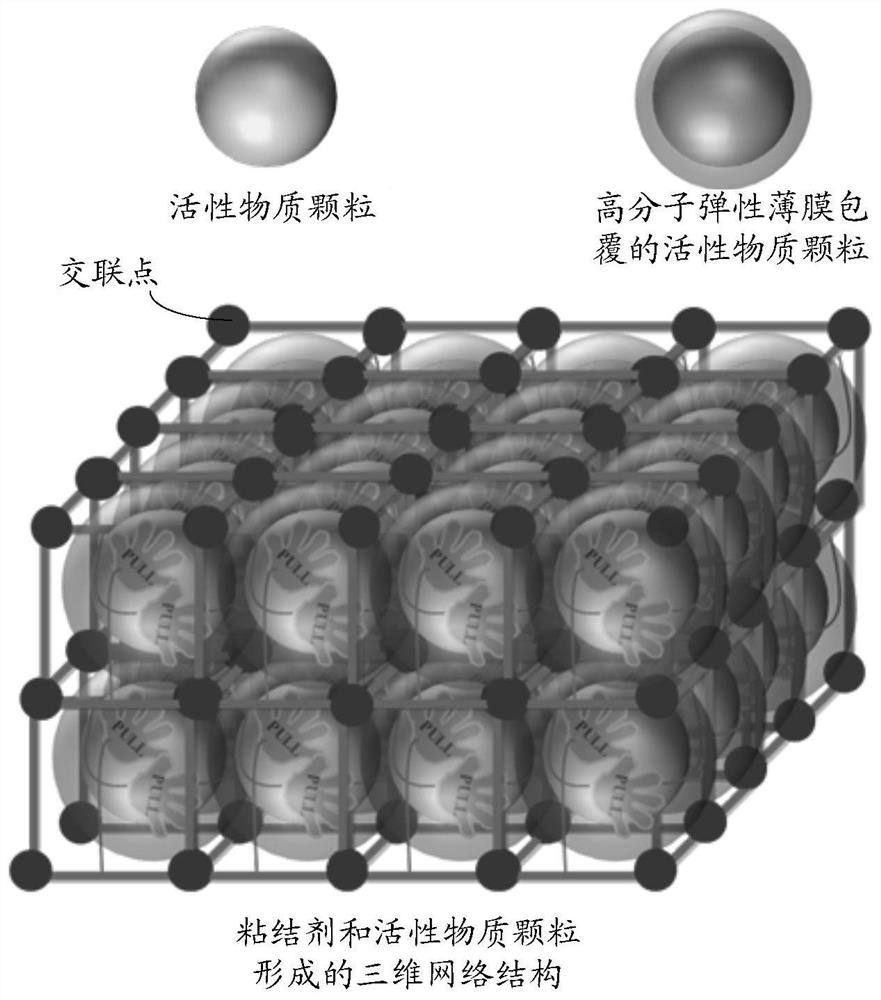

[0059] S3, heating the mixture in a vacuum environment, so that the active groups on the surface of the active material particles and the epoxy groups of the electrochemical cell binder undergo an in-situ crosslinking reaction to obtain a three-dimensional network structure.

[0060] In step S1, the solvent may be water or an organic solvent.

[0061] In step S2, the first repeating unit on the binder can play a preliminary binding role, so as to initially bind the active material particles and the conductive agent together.

[0062] When the active group is an amino group, a polymer elastic film and a three-dimensional network structure can be formed in step S2. At this time, the function of step S3 is only to dry...

Embodiment 1

[0068] Using glycidyl methacrylate and hydrolyzed glycidyl methacrylate as raw materials, in anhydrous organic solvent tetrahydrofuran, in an atmosphere of argon or nitrogen gas protection, at 60 ° C, through a free radical initiator couple Azoisobisbutyronitrile (AIBN) free radicals initiate polymerization to obtain the binder shown in structural formula II, and the specific reaction formula is as follows:

[0069]

Embodiment 2

[0071] Using glycidyl methacrylate and methacrylic acid as raw materials, in anhydrous organic solvent tetrahydrofuran, oxidative polymerization of benzoyl peroxide (BPO) under the condition of 70 ° C, to obtain the binder shown in the structural formula III, The specific reaction formula is as follows:

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com