Preparation method of superhydrophilic anti-pollution PVDF (polyvinylidene fluoride) separation membrane

A separation membrane and anti-pollution technology, applied in semi-permeable membrane separation, chemical instruments and methods, permeation/dialysis water/sewage treatment, etc., can solve problems such as strong hydrophobicity, and achieve easy operation, easy industrial implementation, and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Soak the PVDF separation membrane in clean water for 24 h to remove the impurities on the surface of the PVDF separation membrane (denoted as P0). Place the pretreated isolate membrane in a polytetrafluoroethylene closed box (single-sided reaction box), configure 1 M 1,4-butanediamine and dissolve it in sodium carbonate buffer solution (adjust pH=11.0), 200 rpm, 25 o Under the condition of C, react for 12 h until a light yellow ammonium salt compound layer appears on the membrane. After washing with water and ethanol alternately for 24 h, at 40 o Under vacuum drying under C conditions, the PVDF separation membrane obtained after the first step modification (denoted as P-NH 2 ). The resulting membrane P-NH 2 Soak it face up in 150 mL of absolute ethanol, add 3 mL of epichlorohydrin dropwise to protect the device with nitrogen, slowly add 40 mg of benzyltriethylammonium chloride, at 100 rpm, 65 o C for 5 h, then add 5 mL of 0.06 M sodium hydroxide solution dropwise, ...

Embodiment 2

[0031] Soak the PVDF separation membrane in clean water for 24 h to remove the impurities on the surface of the PVDF separation membrane (denoted as P0). Place the pretreated isolate membrane in a polytetrafluoroethylene closed box (single-sided reaction box), configure 1 M 1,4-pentanediamine and dissolve it in sodium carbonate buffer solution (adjust pH=11.0), placed in a shaker, 200 rpm, 25 o Under the condition of C, react for 12 h until a light yellow ammonium salt compound layer appears on the membrane. After washing with water and ethanol alternately for 24 h, at 40 o Under vacuum drying under C conditions, the PVDF separation membrane obtained after the first step modification (denoted as P-NH 2 ). The resulting membrane P-NH 2 Soak in 150 mL of absolute ethanol with the front side up, add 3 mL of epichlorohydrin dropwise to protect the device with nitrogen, slowly add 40 mg of benzyltriethylammonium chloride, at 100rpm, 65 o C for 5 h, then add 5 mL of 0.06 M sodi...

Embodiment 3

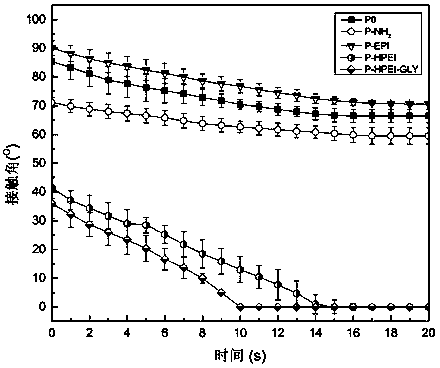

[0033] Contact angle test: Use a contact angle tester to test the contact angle of water on the PVDF membrane surface.

[0034] After testing, the P0 contact angle of the film obtained in Example 1 is 85-95 o , after modification, the contact angle ratio of P-HPEI and P-HPEI-GLY decreased significantly to 30-40 o , and drop to 0 within 15 s o , which proves that the modified membrane has good hydrophilicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com