Metal ion adsorption sewage separation membrane preparation method

A technology of metal ion and separation membrane, which is applied in the direction of adsorption water/sewage treatment, semi-permeable membrane separation, water/sewage treatment, etc. It can solve the problems of insufficient performance and complicated preparation process of adsorption membrane, so as to improve complexation, The effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

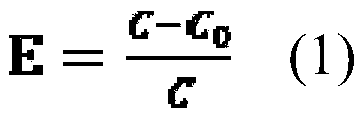

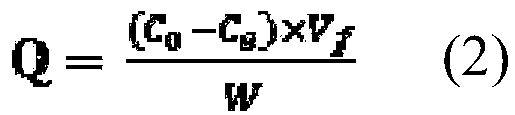

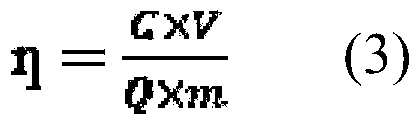

Method used

Image

Examples

Embodiment 1

[0040] First, ultrasonically disperse 100mg of graphene oxide in 100mL of deionized water, add 2g of tannin, heat the solution to 50°C and stir for 12h. The product is filtered through a membrane with a pore size of 0.2μm, then washed, dried and ground to obtain polyphenols Modified graphene oxide (TA-GO).

[0041] 2gTA-GO was ultrasonically dispersed in 84g DMF in N 2 Slowly add 12.5g of dried and pretreated PVDF powder (average molecular weight 100,000-400,000) and 1.5g of pore-forming agent polyvinylpyrrolidone K30 to the dispersion liquid under protection, stir and react for 24 hours to make the casting liquid uniform and stable, and finally It was placed in a vacuum oven for degassing for 6 h.

[0042] Pour the prepared film casting solution on a glass plate, scrape out a flat film with uniform thickness and consistency with a scraper, and then place it in a water coagulation bath to solidify to form a film. After taking it out, wash it several times with deionized water,...

Embodiment 2

[0044] First, ultrasonically disperse 100mg of graphene oxide in 100mL of deionized water, then add 2g of dopamine, heat the solution to 50°C and stir for 12h, the product is filtered through a membrane with a pore size of 0.2μm, then washed, dried and ground for storage to obtain dopamine-modified Graphene oxide (DA-GO).

[0045] 1 g DA-GO was ultrasonically dispersed in 84 g DMF in N 2 Slowly add 13.5g of dried and pretreated PVDF powder (average molecular weight 100,000-400,000) and 1.5g of pore-forming agent polyvinylpyrrolidone K30 to the dispersion liquid under protection, stir and react for 24 hours to make the casting liquid uniform and stable, and finally It was placed in a vacuum oven for degassing for 6 h.

[0046] Pour the prepared film casting solution on a glass plate, scrape out a flat film with uniform thickness and consistency with a scraper, and then place it in a water coagulation bath to solidify to form a film. After taking it out, wash it several times ...

Embodiment 3

[0048] First, ultrasonically disperse 100 mg of graphene oxide in 100 mL of deionized water, add 2 g of pyrogallic acid, heat the solution to 50°C and stir for 12 hours, filter the product with a membrane with a pore size of 0.2 μm, then wash it, dry it and store it to obtain pyrogallate Acid-modified graphene oxide (PG-GO).

[0049] 1.5 g PG-GO was ultrasonically dispersed in 84 g DMF in N 2 Slowly add 13.5g of dried and pretreated PVDF powder (average molecular weight 100,000-400,000) and 1g of pore-forming agent polyvinylpyrrolidone K30 to the dispersion liquid under protection, and stir for 24 hours to make the casting liquid uniform and stable. It was placed in a vacuum oven for degassing for 6 hours.

[0050] Pour the prepared film casting solution on a glass plate, scrape out a flat film with uniform thickness and consistency with a scraper, and then place it in a water coagulation bath to solidify to form a film. After taking it out, wash it several times with deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com