Preparation method of vitrification agent and vitrification liquid and vitrification process

A vitrification agent and vitrification technology, which is applied in the coating process of metal materials, etc., can solve the problems of insufficient corrosion resistance, easy rust return time, etc., and achieve the goals of increasing density, shortening processing time, and improving corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A vitrifying agent, comprising the following components and the mass parts of each component,

[0077] 5-10 parts of sodium fluozirconate,

[0078] Potassium fluotitanate 3-5 parts,

[0079] 5-10 parts of silane coupling agent,

[0080] 5-8 parts of tartaric acid,

[0081] 62-77 parts of deionized water,

[0082] 10-15 parts of nano silicon powder.

[0083] Taking the preparation of 1000L as an example, the preparation method of ceramic solution is as follows:

[0084] S1: Add 800L of deionized water to the mixing tank, then add 15-35L of the above ceramic agent and stir evenly to obtain the pre-mixed solution; S2: Add deionized water to the pre-mixed solution, and make the pre-mixed solution The number is corrected to 1000 copies;

[0085] S3: Detect the pH value of the pre-prepared solution, and add ammonia water to adjust the pH value of the pre-prepared solution to 3.5-5.5.

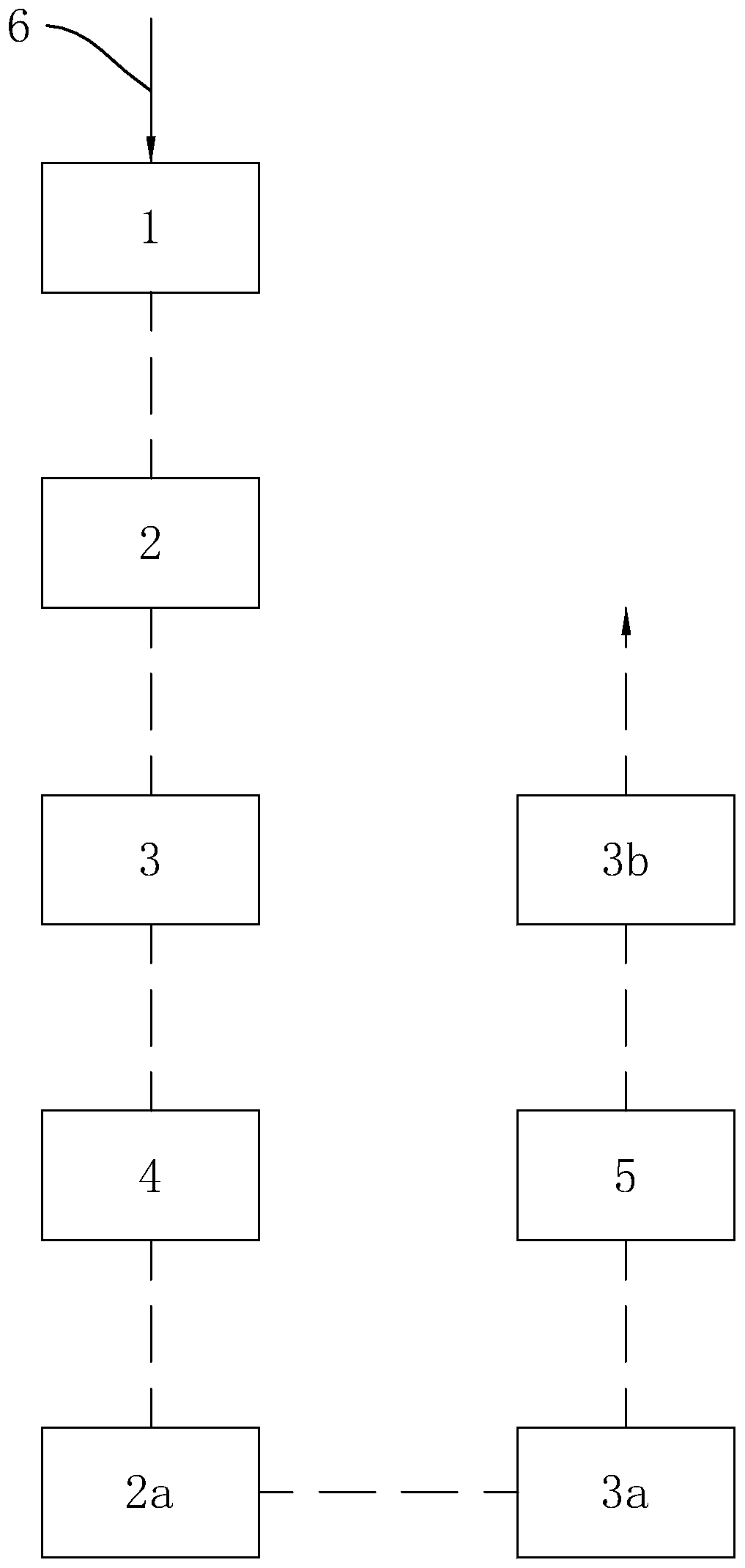

[0086] as attached figure 1 Shown, a kind of vitrification process using above-ment...

Embodiment 2

[0100] A kind of vitrifying agent, it is based on the basis of embodiment 1, and it also comprises thickening agent 5-8 parts, and here thickening agent is sodium alginate.

[0101] A vitrifying liquid, prepared according to the preparation method in Example 1, using the above-mentioned vitrifying agent.

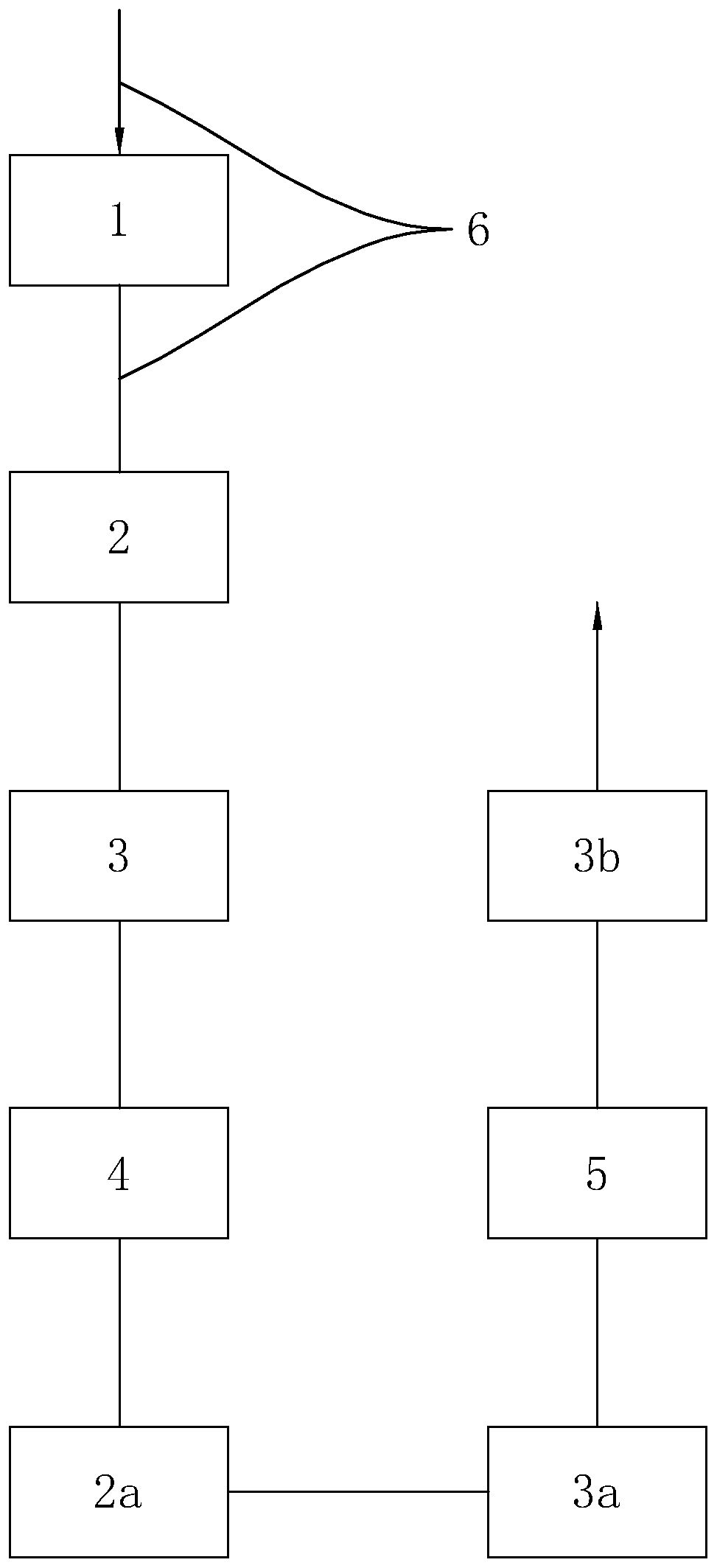

[0102] as attached figure 2 Shown, a kind of vitrification process using above-mentioned preparation vitrification liquid, it comprises the following steps,

[0103] X1: The workpiece is mounted under the transmission hanger 6 and sprayed with the cleaning solution through the phosphorus-free cleaning room 1 for phosphorus-free pre-degreasing. The degreasing agent is used as a neutral degreasing agent, and the temperature is controlled at 28 ° C. Then it is transported by the conveyor belt and kept immersed Perform ultrasonic phosphorus-free cleaning through the first ultrasonic cleaning tank 2, the ultrasonic frequency is 20-22kHz, the water temperature in the first ultraso...

Embodiment 3

[0121] A kind of vitrifying agent, it is based on the basis of embodiment 2, and it also comprises fatty alcohol polyoxyethylene ether 7-15 parts.

[0122] A vitrifying liquid, prepared according to the preparation method in Example 1, using the above-mentioned vitrifying agent.

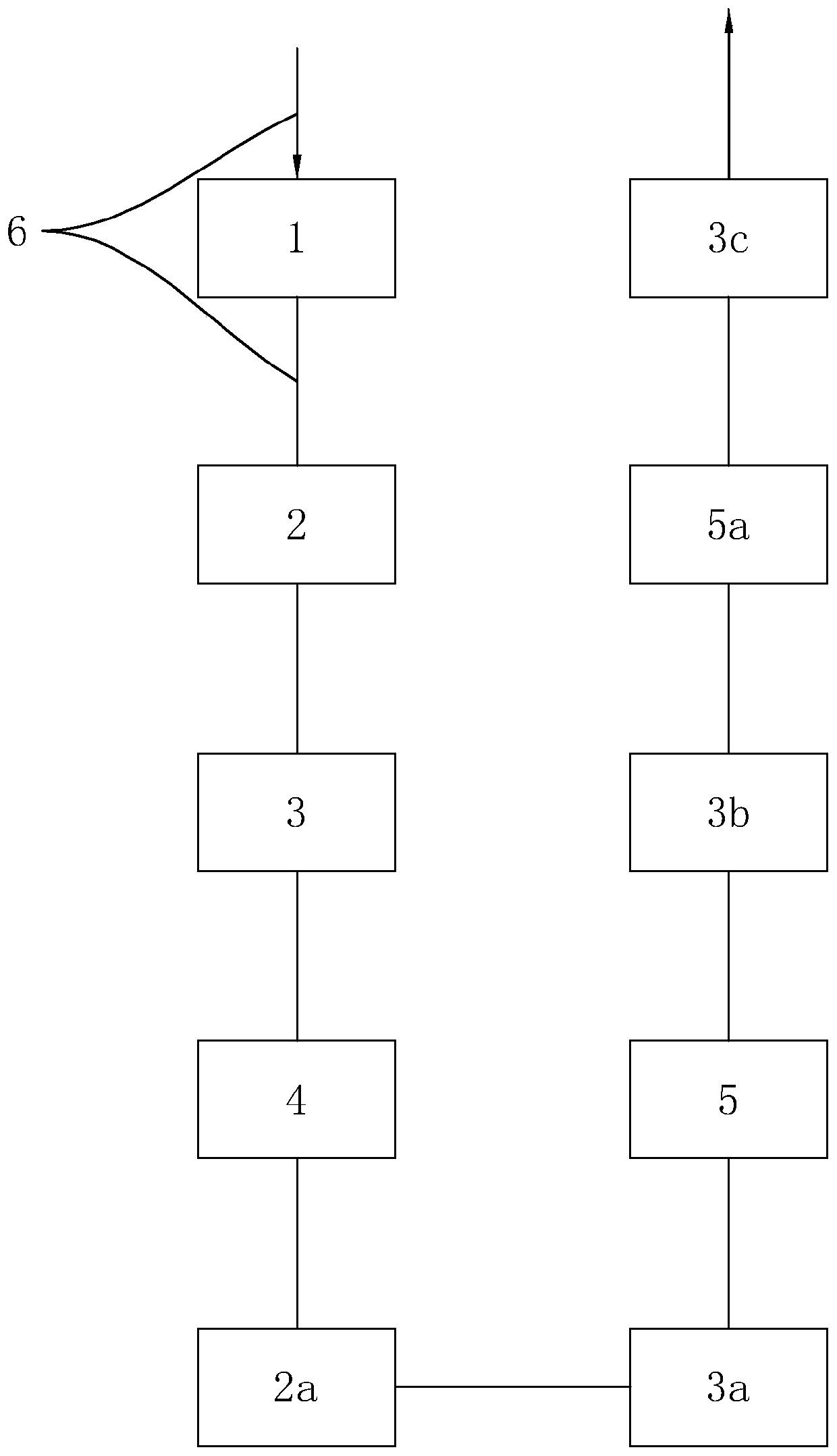

[0123] A kind of vitrification process, which includes the following steps are the same as those in Example 2, the difference is that the vitrification liquid is used in that the above-mentioned vitrification is also obtained according to the preparation method of Example 1.

[0124] According to above-mentioned vitrification process, designed embodiment 3A-3E specific parameter is shown in the following table.

[0125]

[0126] The sample that embodiment 3A-3E makes is carried out the test of vitrified film adhesion strength according to the test method specified in " GB9286-1998 Color Paint and Varnish Paint Film Cross-cut Test ", test result is distinguished with its stipulation classification,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com