Double-phase laminated structure steel plate and preparation method thereof

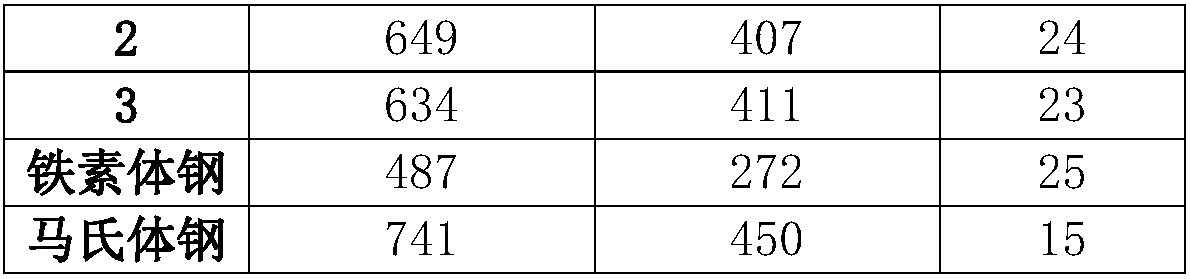

A stacking and organization technology, applied in the field of steel plate manufacturing, can solve the problem that steel cannot be combined at the same time, and achieve the effects of low sensitivity to cold cracks and hot cracks, simple technical route, high strength and toughness matching and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

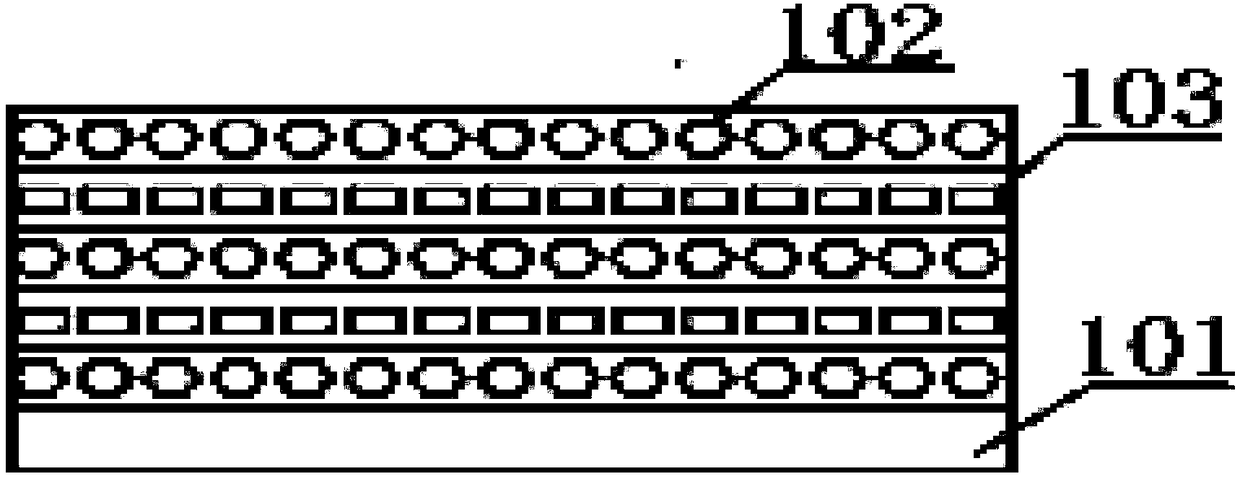

Image

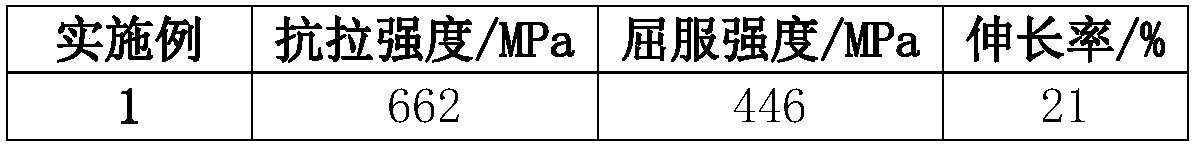

Examples

Embodiment 1

[0028] The preparation method of the dual-phase laminated structure steel plate of this embodiment includes:

[0029] (1) Use ferrite welding wire to surfacing a layer of ferrite layer with a certain height on one side of the low carbon steel substrate. The surfacing welding conditions are: wire feeding speed: 5mm / min, welding speed: 300mm / min, arc length Correction: 10, arc thrust: -2.5, distance between centers of each weld bead: 5mm, current: 140A, voltage: 14.3V, shielding gas flow: 25L / min.

[0030] (2) Using the same surfacing welding process parameters, a layer of martensitic layer is surfacing with martensitic stainless steel welding wire on the ferrite layer.

[0031] (3) Repeat the above operation, alternately stacking 6 times. The ferrite surfacing layer accounts for 65% of the entire surfacing layer, and the formed martensitic surfacing layer accounts for 35% of the entire surfacing layer.

[0032] (4) Roll the welded plate in a rolling mill, with a reduction of ...

Embodiment 2

[0035] The preparation method of the dual-phase laminated structure steel plate of this embodiment includes:

[0036] (1) Use ferrite welding wire to surfacing a layer of ferrite layer with a certain height on one side of the low carbon steel substrate. The surfacing welding conditions are: wire feeding speed: 5mm / min, welding speed: 250mm / min, arc length Correction: 10, arc thrust: -2.5, distance between centers of each weld bead: 5mm, current: 160A, voltage: 15V, shielding gas flow: 23L / min.

[0037] (2) Using the same surfacing welding process parameters, a layer of martensitic layer is surfacing with martensitic stainless steel welding wire on the ferrite layer.

[0038] (3) Repeat the above operation, alternately stacking 5 times. The ferrite surfacing layer accounts for 70% of the entire surfacing layer, and the formed martensitic surfacing layer accounts for 30% of the entire surfacing layer.

[0039] (4) Roll the welded plate in a rolling mill, the reduction in each ...

Embodiment 3

[0042] The preparation method of the dual-phase laminated structure steel plate of this embodiment includes:

[0043] (1) Use ferrite welding wire to surfacing a layer of ferrite layer with a certain height on one side of the low carbon steel substrate. The surfacing welding conditions are: wire feeding speed: 5mm / min, welding speed: 350mm / min, arc length Correction: 10, arc thrust: -2.5, distance between centers of each weld bead: 5mm, current: 120A, voltage: 10V, shielding gas flow: 20L / min.

[0044] (2) Using the same surfacing welding process parameters, a layer of martensitic layer is surfacing with martensitic stainless steel welding wire on the ferrite layer.

[0045] (3) Repeat the above operation, alternately stacking 5 times. The ferrite surfacing layer accounts for 60% of the entire surfacing layer, and the formed martensitic surfacing layer accounts for 40% of the entire surfacing layer.

[0046] (4) Roll the welded plate in a rolling mill, with a reduction of 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com