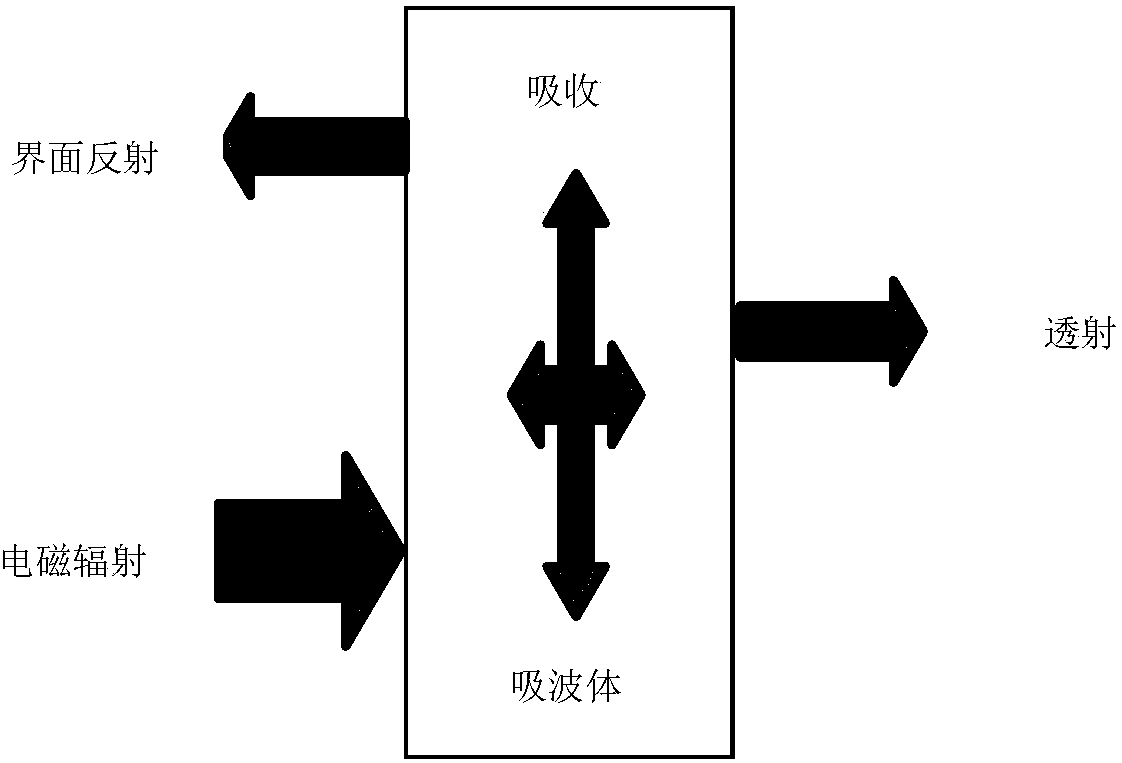

Nano wave-absorbing agent doped single-layer cement-based wave absorber and preparation method thereof

A wave absorbing agent and cement-based technology, applied in the field of modified cement-based composite materials, can solve the problems of not meeting the requirements of high efficiency and light weight of wave absorbing materials, reducing the mechanical properties of composite materials, and being difficult to achieve broadband absorption, etc. The effect of convenience, excellent impact resistance, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

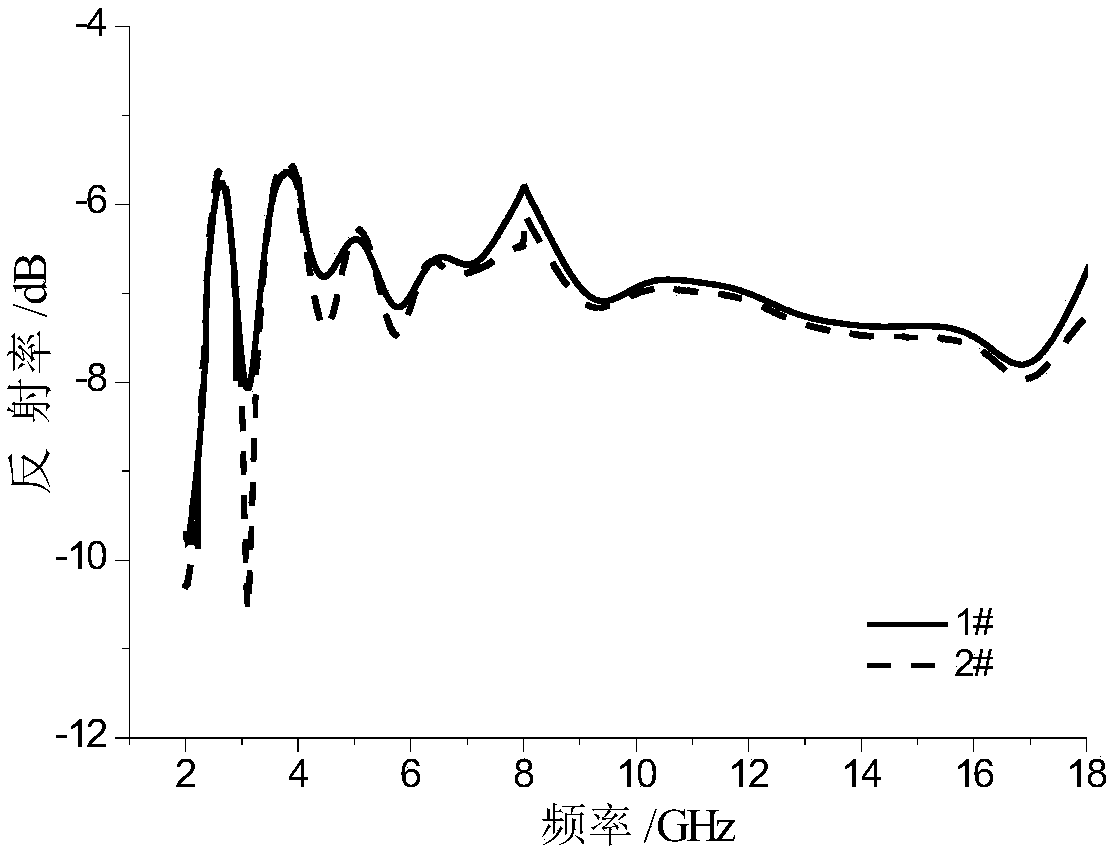

[0034] A single-layer cement-based wave-absorbing body compounded with nano wave-absorbing agents, including cement, silica fume, water, reduced graphene oxide, nanometer ferric oxide, nickel-plated multi-walled carbon nanotubes and a water reducer, wherein, Silica fume, water, reduced graphene oxide, nano-ferric oxide, nickel-plated multi-walled carbon nanotubes and water reducer accounted for 10%, 34%, 0.03%, 2%, 0.5% and 0.33% of the cement mass, respectively.

[0035] The preparation method of the above-mentioned single-layer cement-based wave-absorbing body compounded with nano wave-absorbing agent comprises the following steps: taking cement for later use, taking the cement quality as 1, weighing 10% silica fume according to the mass ratio, pouring the two into stirring Stir the pot evenly. After stirring evenly, weigh 2% nano-ferric oxide and 0.5% nickel-plated multi-walled carbon nanotubes, and stir at a low speed for 2.5 minutes; then add 0.03% reduced graphene oxide t...

Embodiment 2

[0038] A single-layer cement-based wave-absorbing body compounded with nano wave-absorbing agents, including cement, silica fume, water, reduced graphene oxide, nanometer ferric oxide, nickel-plated multi-walled carbon nanotubes and a water reducer, wherein, Silica fume, water, reduced graphene oxide, nano-ferric oxide, nickel-plated multi-walled carbon nanotubes and water reducer accounted for 10%, 37%, 0.03%, 2%, 1% and 0.36% of the cement mass, respectively.

[0039] The preparation method of the above-mentioned single-layer cement-based wave-absorbing body compounded with nano wave-absorbing agent comprises the following steps: taking cement for later use, taking the cement quality as 1, weighing 10% silica fume according to the mass ratio, pouring the two into stirring Stir the pot evenly. After stirring evenly, weigh 2% nano-ferric oxide and 1% nickel-plated multi-walled carbon nanotubes, and stir at a low speed for 2.5 minutes; then add 0.03% reduced graphene oxide to th...

Embodiment 3

[0043] A single-layer cement-based wave-absorbing body compounded with nano wave-absorbing agents, including cement, silica fume, water, reduced graphene oxide, nanometer ferric oxide, nickel-plated multi-walled carbon nanotubes and a water reducer, wherein, Silica fume, water, reduced graphene oxide, nano-ferric oxide, nickel-plated multi-walled carbon nanotubes and water reducer accounted for 10%, 33%, 0.015%, 2%, 0.5% and 0.31% of the cement mass, respectively.

[0044] The preparation method of the above-mentioned single-layer cement-based wave-absorbing body compounded with nano wave-absorbing agent comprises the following steps: taking cement for later use, taking the cement quality as 1, weighing 10% silica fume according to the mass ratio, pouring the two into stirring Stir the pot evenly. After stirring evenly, weigh 2% nano-ferric oxide and 0.5% nickel-plated multi-walled carbon nanotubes, and stir at a low speed for 2.5 minutes; then add 0.015% reduced graphene oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com