A kind of preparation method of modified epoxy resin and its application in heavy-duty anti-corrosion coating

An epoxy resin and liquid epoxy resin technology, applied in the field of coatings, can solve the problems of poor coating compactness, unsatisfactory anti-corrosion performance, poor adhesion between film-forming resin and metal, etc., so as to improve anti-corrosion performance and improve storage. Stability, the effect of improving dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

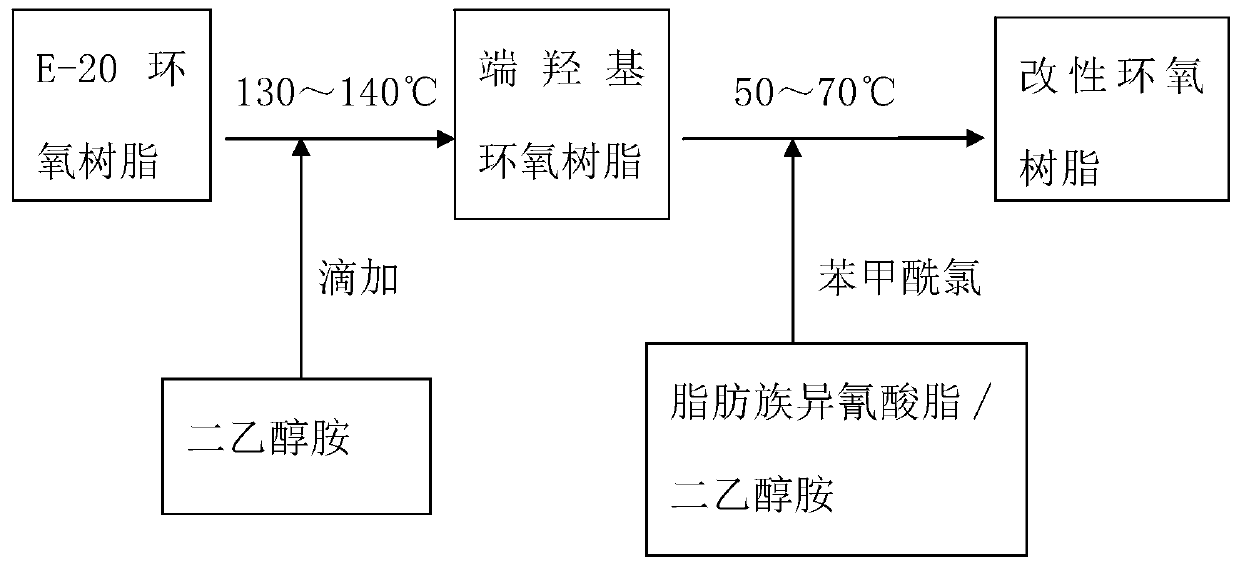

Method used

Image

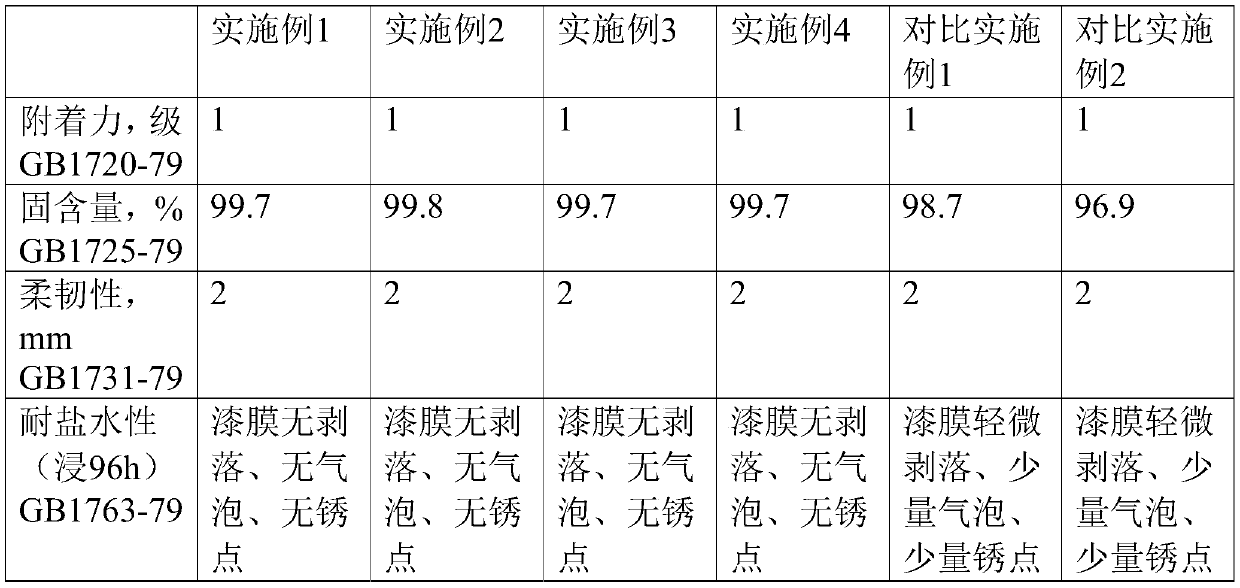

Examples

Embodiment 1

[0037] (1) Preparation of component A:

[0038] ①Synthesis of solvent-free hydroxyl-terminated epoxy resin:

[0039] Put 45 parts of low-molecular liquid epoxy resin, 25 parts of diglycidyl ether and 30 parts of monovalent secondary amine into the reaction kettle and stir. When the temperature is raised to 80°C, keep the temperature for 3 hours, cool and discharge to obtain the solvent-free end Hydroxy epoxy resin.

[0040] ②Pre-dispersion

[0041] Add 1 part of polyacrylate ammonium salt dispersant to the solvent-free hydroxyl-terminated epoxy resin prepared in step ① for pre-dispersion.

[0042] ③Prepare the finished product of component A:

[0043] Mix 2 / 3 of the total pre-dispersed solvent-free hydroxyl-terminated epoxy resin, 5 parts of 800-mesh zinc phosphate, and 0.2 parts of BYK-051 defoamer from BYK to form a color paste, and use a high-efficiency alloy horizontal Sand mill, equipped with superhard ceramic zirconium beads as the grinding medium, disperse until the...

Embodiment 2

[0047] (1) Preparation of component A:

[0048] ①Synthesis of solvent-free hydroxyl-terminated epoxy resin:

[0049] Put 55 parts of low-molecular-weight liquid epoxy resin, 25 parts of diglycidyl ether and 20 parts of monovalent secondary amine into the reaction kettle and stir. When the temperature is raised to 70 ° C, keep the temperature for 3 hours, cool and discharge to obtain the solvent-free end Hydroxy epoxy resin.

[0050] ②Pre-dispersion

[0051] Add 1.5 parts of polyacrylate ammonium salt dispersant to the solvent-free hydroxyl-terminated epoxy resin prepared in step ① for pre-dispersion.

[0052]③Prepare the finished product of component A:

[0053] Mix 2 / 3 of the total pre-dispersed solvent-free hydroxyl-terminated epoxy resin, 8 parts of 1250-mesh aluminum tripolyphosphate, and 0.2 parts of BYK-051 defoamer from BYK to form a color paste, and use high-efficiency alloy Horizontal sand mill, equipped with superhard ceramic zirconium beads as the grinding mediu...

Embodiment 3

[0058] (1) A component is prepared according to the following steps:

[0059] ①Synthesis of solvent-free hydroxyl-terminated epoxy resin:

[0060] Put 60 parts of low-molecular-weight liquid epoxy resin, 20 parts of diglycidyl ether and 20 parts of monovalent secondary amine into the reaction kettle and stir. When the temperature is raised to 65 ° C, keep the temperature for 3 hours, cool and discharge to obtain the solvent-free end Hydroxy epoxy resin.

[0061] ②Pre-dispersion

[0062] Add 1.5 parts of polyacrylate ammonium salt dispersant to the solvent-free hydroxyl-terminated epoxy resin prepared in step ① for pre-dispersion.

[0063] ③Prepare the finished product of component A:

[0064] Mix 2 / 3 of the total pre-dispersed solvent-free hydroxyl-terminated epoxy resin, 8 parts of 1250-mesh aluminum tripolyphosphate, and 0.2 parts of BYK-051 defoamer from BYK to form a color paste, and use high-efficiency alloy Horizontal sand mill, equipped with superhard ceramic zircon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com