Method of using subcritical water to prepare caramel color and application thereof

A technology of subcritical water and caramel color, which is applied in the field of subcritical water to prepare caramel color, can solve the problems of low production efficiency and difficulty in removal, achieve small footprint, low equipment requirements, and save the process of replacing the concentration container Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

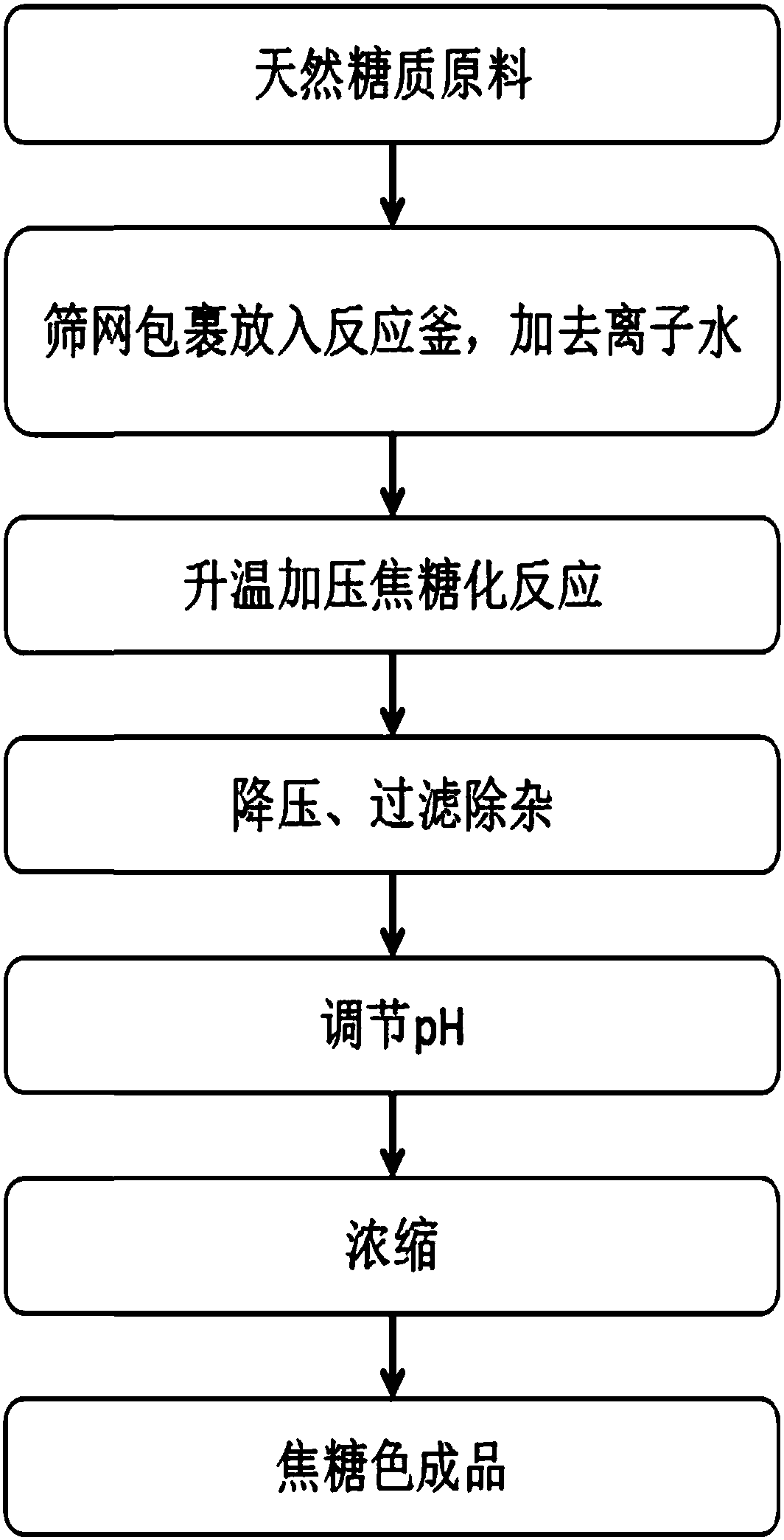

[0035] A method for preparing caramel color with subcritical water, according to the following steps:

[0036] (1) Crush the sucrose raw material to 60 mesh, weigh 1.0Kg of sucrose powder, and wrap it in 300 mesh nylon cloth for use;

[0037] (2) Put the wrapped raw materials into the subcritical reactor, add 3L of deionized water according to the solid-to-liquid ratio of 1:3Kg / L, the heating time is 80min, the reaction temperature is 190℃, the reaction pressure is 3MPa, and the reaction time is 30min , Caramelization reaction;

[0038] (3) After the reaction is over, open the gas release valve, adjust the tank to normal pressure, and filter the obtained mixture with an 80-mesh screen, and then filter it through a 300-mesh screen for a second time to remove impurities to obtain 2.9Kg of filtrate;

[0039] (4) Adjust the pH of the filtrate to 5.8;

[0040] (5) Concentrate the pH-adjusted solution to 0.31 times the mass to obtain a caramel color of 0.9Kg. Measure the absorbance value at ...

Embodiment 2

[0042] A method for preparing caramel color with subcritical water, according to the following steps:

[0043] (1) Crush the wheat flour to 80 mesh, weigh 1.0 Kg of the powder, and wrap it in 300 mesh special nylon cloth for use;

[0044] (2) Put the wrapped raw materials into the subcritical reactor, add 2.5L of deionized water according to the solid-liquid ratio of 1:2.5Kg / L, the heating time is 90min, the reaction temperature is 200℃, the reaction pressure is 3.5MPa, and the reaction The time is 30min to carry out the caramelization reaction;

[0045] (3) After the reaction is over, open the gas release valve, adjust the tank to normal pressure, and filter the obtained mixture with an 80-mesh screen, and then filter it through a 300-mesh screen for a second time to remove impurities to obtain 2.3Kg of filtrate;

[0046] (4) Adjust the pH of the filtrate to 6.0;

[0047] (5) Concentrate the pH-adjusted solution to 0.43 times the mass to obtain 1.0Kg of caramel color. Measure the abso...

Embodiment 3

[0049] A method for preparing caramel color with subcritical water, according to the following steps:

[0050] (1) Crush the raw material of pumpkin powder to 80 mesh, weigh 1.0 kg of pumpkin powder containing pumpkin polysaccharide, and wrap it in 300 mesh nylon cloth for use;

[0051] (2) Put the wrapped raw materials into the subcritical reactor, add 3L of deionized water according to the solid-liquid ratio of 1:3Kg / L, the heating time is 60min, the reaction temperature is 170℃, the reaction pressure is 3.0MPa, and the reaction time is 30min, carry out caramelization reaction;

[0052] (3) After the reaction is over, open the gas release valve, adjust the tank to normal pressure, and filter the obtained mixture with an 80-mesh screen, and then filter it through a 300-mesh screen for a second time to remove impurities to obtain 2.6Kg of filtrate;

[0053] (4) Adjust the pH of the filtrate to 6.0;

[0054] (5) Concentrate the pH-adjusted solution to 0.38 times the mass to obtain a car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com