Auxiliary equipment and method for improving ion nitriding efficiency of surface of low-alloy structural steel

An auxiliary equipment, ion nitriding technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as low nitriding efficiency, achieve fast nitriding speed, improve hardness and wear resistance , The effect of maintaining discharge stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A kind of auxiliary equipment and method for improving the efficiency of ion nitriding on the surface of low-alloy structural steel proposed by the present invention are described in detail in conjunction with the accompanying drawings and embodiments as follows:

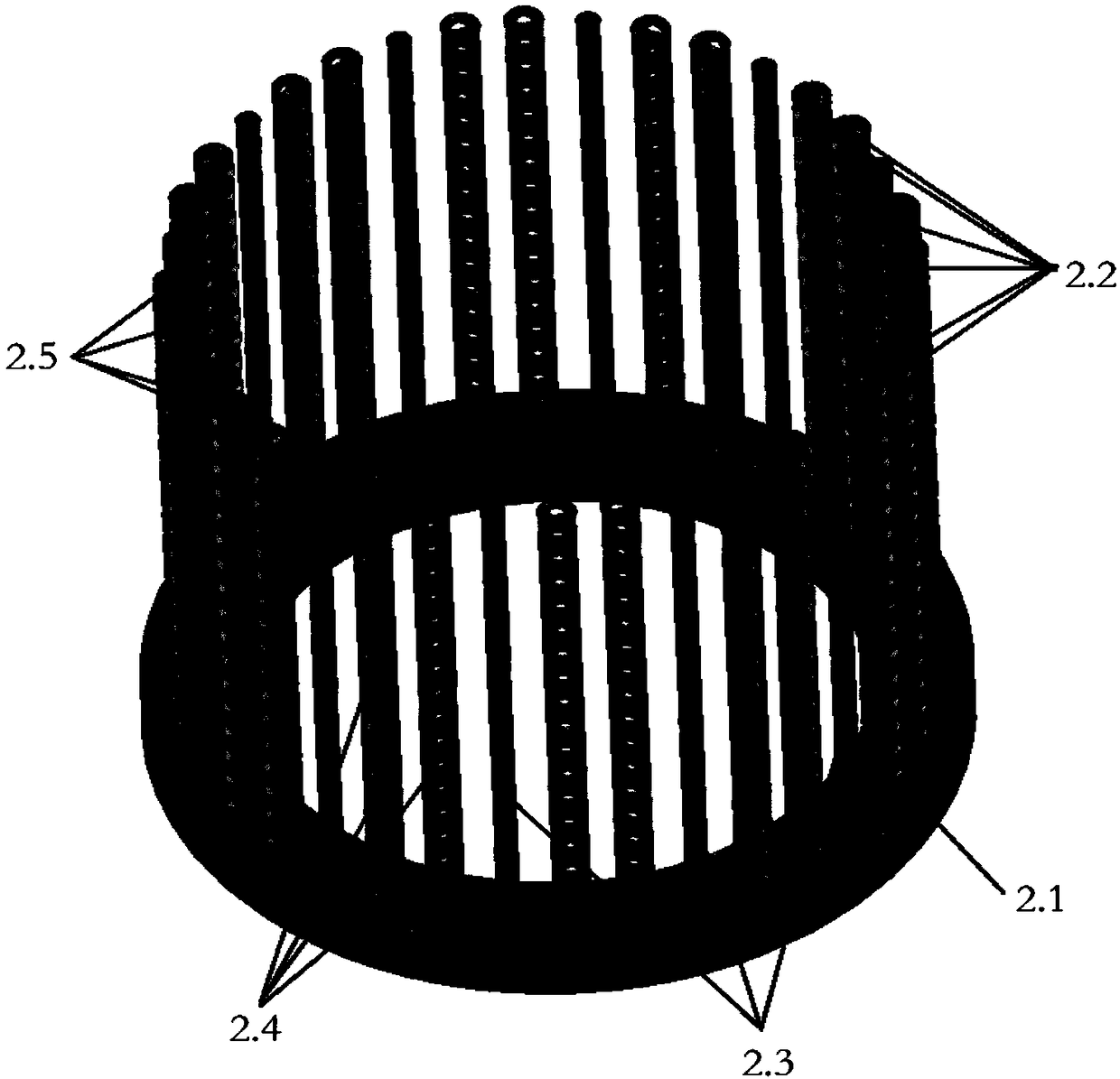

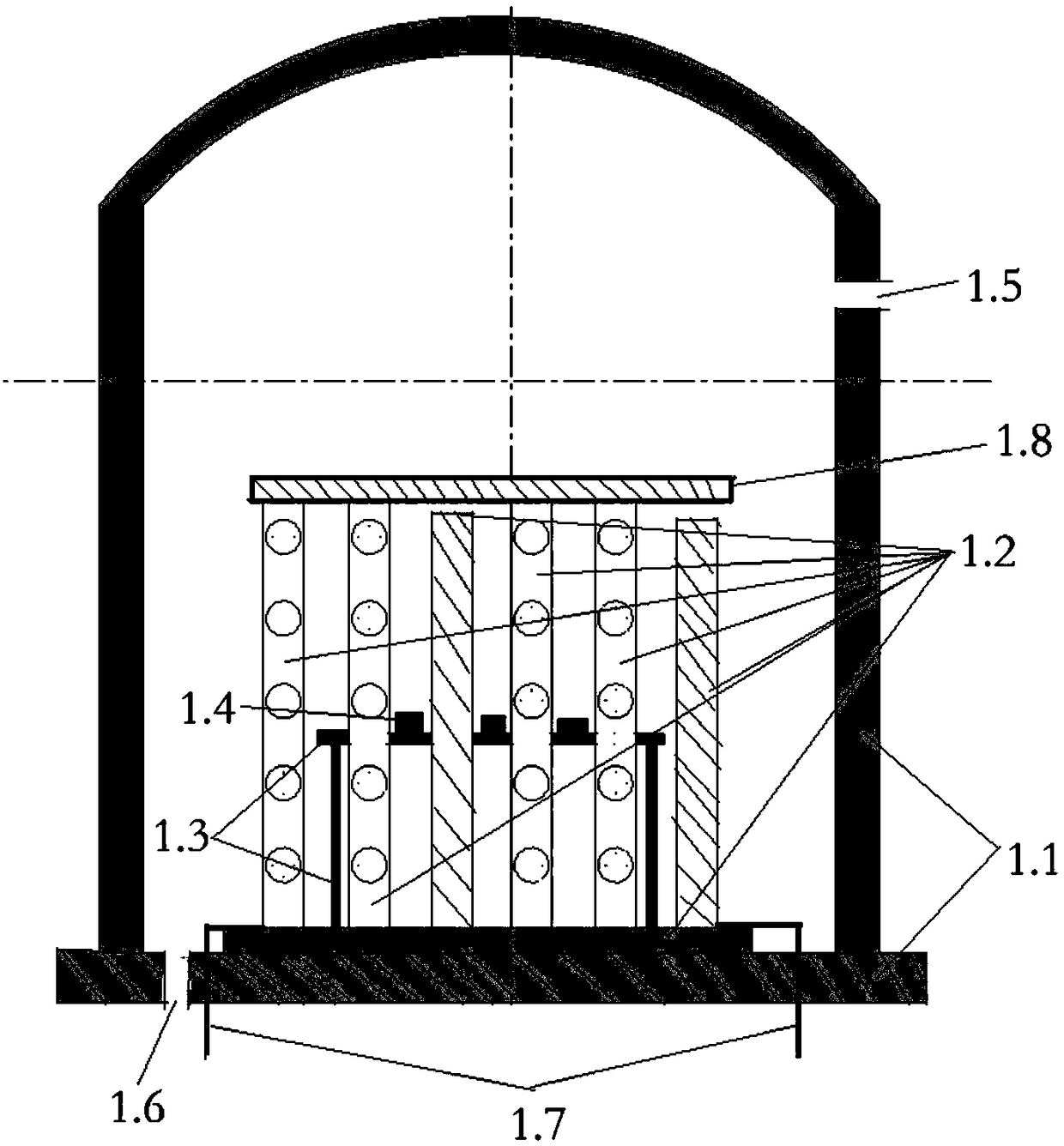

[0032] Auxiliary equipment structure of the present invention such as figure 1 As shown, including an insulating base 2.1, the inner and outer radius and height of the base can be adjusted according to the size of the processed workpiece and the material used; the insulating base 2.1 is inserted into a radius of 40-200mm surrounded by a plurality of cathode circular tubes 2.2 and anode rods 2.3 The cylindrical structure, the height of which can be adjusted according to the workpiece to be processed; the cathode tube 2.2 is a hollow cylinder with an inner radius of 4-8mm and a wall thickness of 3-6mm. Through hole 2.4, the size and spacing of the through hole can be adjusted according to the diameter of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com