Pigment printing binder and pigment printing production technology

A paint printing and adhesive technology, which is applied to the production process of paint printing and the field of paint printing adhesives, achieves the effects of increasing controllability, eliminating pre-baking treatment steps and increasing varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

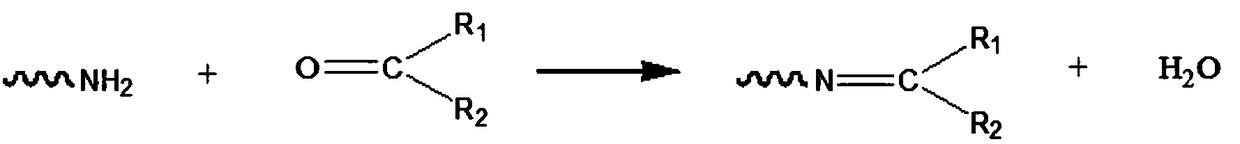

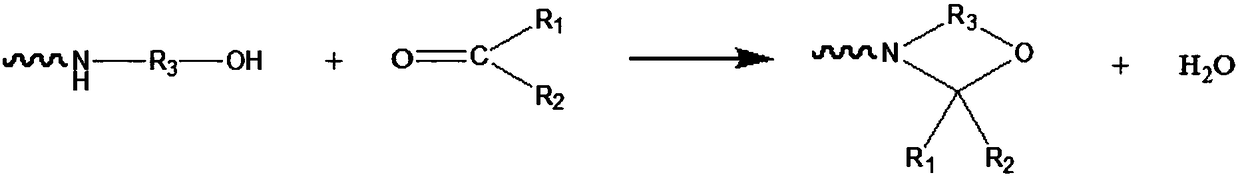

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to a pigment printing adhesive, which is an anhydrous and solvent-free polyurea substance, mainly composed of an isocyanate component and a latent curing agent through a speed-controlled The curing reaction forms a polyurea binder that adheres the pigment to the surface of the fabric.

[0038] The isocyanate component includes: one or any mixture of polyisocyanate monomers and isocyanate-terminated prepolymers;

[0039]Among them, the polyisocyanate monomer requires an average functional group of at least 2, and the preferred polyisocyanate monomers are: toluene diisocyanate (TDI), diphenylmethane diisocyanate (MDI), isophorone diisocyanate (IPDI), bicyclic Hexylmethane diisocyanate (HMDI), hexamethylene diisocyanate (HDI), lysine diisocyanate (LDI), hexamethylene diisocyanate trimer (HDI trimer)

[0040] The preferred isocyanate-terminated prepolymer is: NCO is prepared by reacting polyether polyol, polyester polyol or amino-terminated polyethe...

Embodiment 2

[0058] This embodiment relates to the application of the polyurea adhesive of Embodiment 1 in the fabric pigment printing process.

Embodiment 21

[0060] Pigment printing of fabrics is carried out as follows:

[0061] a, pulping: get 290 grams of terminal isocyanate prepolymer A-1 and 70 grams of isocyanate A-2 and mix evenly, then add and mix with 200 grams of paint color paste, 180 gram thickener (using conventional commercially available paint color paste and Thickener) latent curing agent B-1 mixture 530 grams, blend evenly, obtain coating slurry;

[0062] b. Use the paint slurry to print on the fabric, and then bake at 120°C for 5 minutes to complete the printing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com