Fuel gas evaporator

A gas steam and steam generator technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of small heat absorption range at the evaporation end, low content of active ingredients, and low degree of intelligence, so as to avoid heating Unevenness, reducing volume and footprint, avoiding local overheating or undercooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

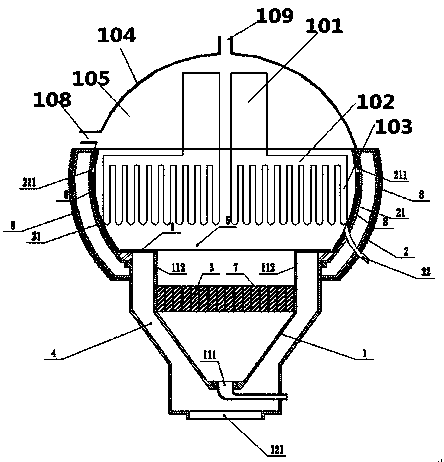

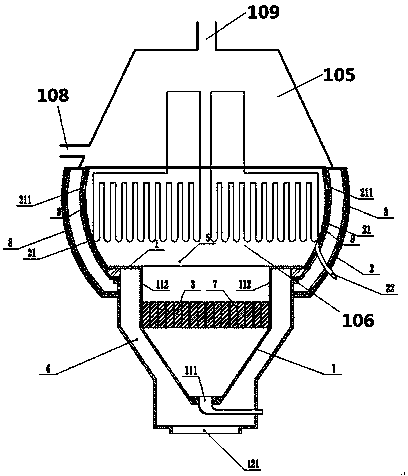

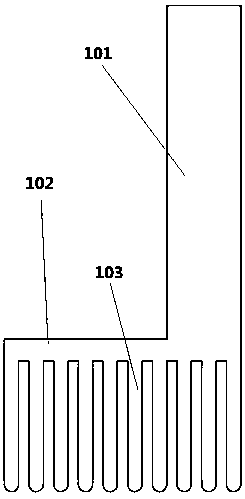

[0044] like Figure 1-8 Disclosed is a gas-fired steam generator using heat pipes, the steam generator includes a water tank 105 and a heat pipe 10, the water tank 105 includes a water inlet 108 and a steam outlet 109, and the heat pipe includes a vertical part 101, a horizontal part 102 and a heat pipe 10. Vertical pipe 103, wherein the bottom end of the vertical part 101 communicates with the horizontal part 102, and the bottom of the horizontal part 102 communicates with a plurality of vertical pipes 103, wherein the vertical pipe 103 is the evaporation end of the heat pipe, and the vertical part 101 is the end of the heat pipe. condensing end. The vertical portion 101 extends into the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com