hemt device and its preparation method

A device and cap layer technology, applied in the field of microelectronics, can solve the problems of low repeatability, unsatisfactory effect, high time consumption, etc., achieve excellent stress behavior, good metal adhesion, and improve device reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

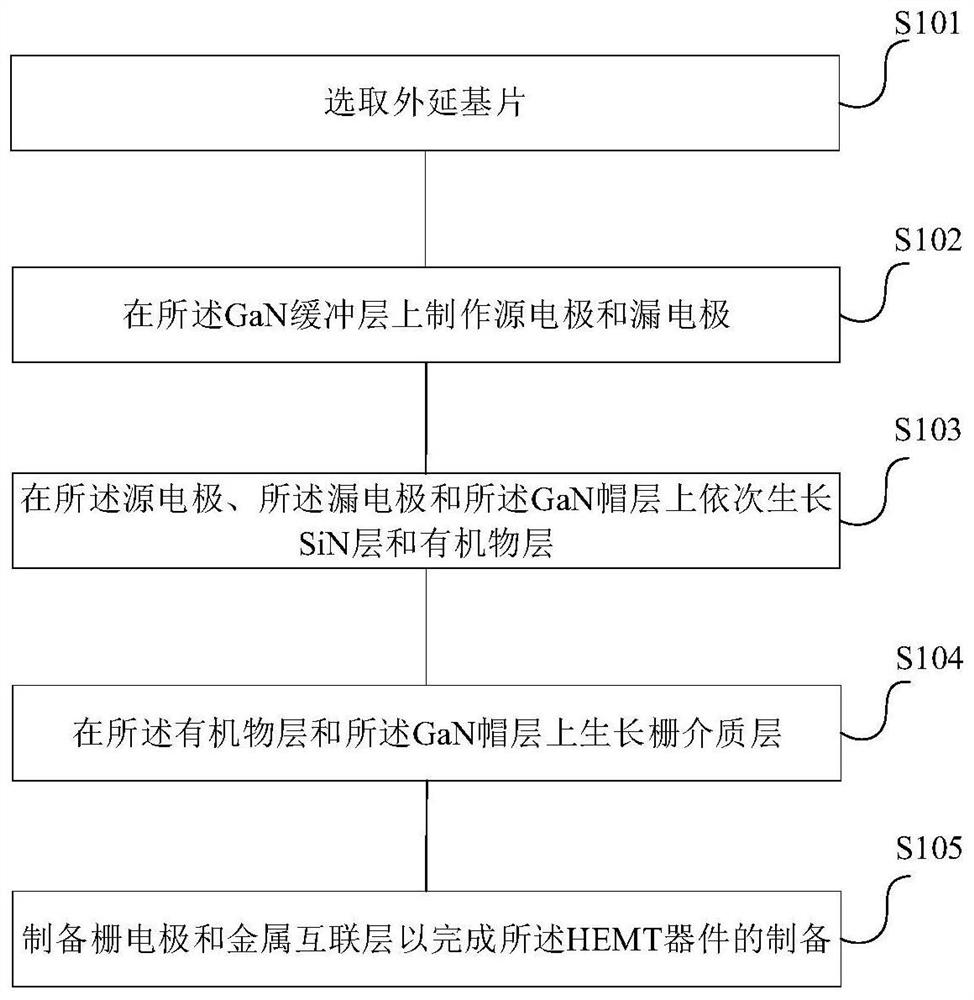

[0028] See figure 1 , figure 1 A schematic flow chart of a preparation method for a HEMT device provided in an embodiment of the present invention, including:

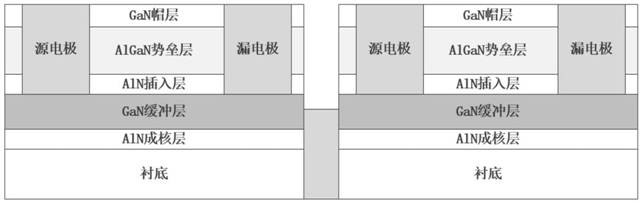

[0029] S101. Select an epitaxial substrate; the epitaxial substrate sequentially includes a substrate, a nucleation layer, a GaN buffer layer, an AlN insertion layer, an AlGaN barrier layer, and a GaN cap layer from bottom to top;

[0030] S102, forming a source electrode and a drain electrode on both ends of the GaN buffer layer;

[0031] S103, sequentially growing a SiN layer and an organic layer on the source electrode, the drain electrode, and the GaN cap layer to form a passivation layer;

[0032] S104, growing a gate dielectric layer on the organic layer and the GaN cap layer;

[0033] S105 , preparing a gate electrode and a metal interconnection layer to complete the preparation of the HEMT device.

[0034] Preferably, S102 may include:

[0035] S1021, photoetching a source electrode region and a drain elec...

Embodiment 2

[0054] Please refer to Figure 2a-2i , Figure 2a-2i The schematic flow chart of the preparation process of a HEMT device provided by the embodiment of the present invention, this embodiment describes the preparation method of the HEMT device of the present invention in detail on the basis of the first embodiment. include:

[0055] S201, such as Figure 2a As shown, the source and drain electrodes are fabricated on the GaN buffer layer of the epitaxial substrate.

[0056] Among them, the epitaxial substrate can be the initially purchased epitaxial substrate, or it can be the manufactured epitaxial substrate, and the epitaxial substrate includes substrate, nucleation layer, GaN buffer layer, AlN insertion layer, AlGaN potential barrier layer and GaN cap layer.

[0057] Specifically, the substrate is made of sapphire material.

[0058] S2011, photoetching the source electrode region and the drain electrode region on the GaN cap layer:

[0059] First, bake the epitaxial sub...

Embodiment 3

[0137] Further, please refer to image 3 , image 3 The schematic flow chart of another HEMT device manufacturing method provided by the embodiment of the present invention is described in detail in this embodiment on the basis of the first embodiment. Specifically include:

[0138] S301, fabricating a source electrode and a drain electrode on an epitaxial substrate.

[0139] Among them, the epitaxial substrate can be the initially purchased epitaxial substrate, or it can be the manufactured epitaxial substrate, and the epitaxial substrate includes substrate, nucleation layer, GaN buffer layer, AlN insertion layer, AlGaN potential barrier layer and GaN cap layer.

[0140] Specifically, the substrate is a SiC substrate.

[0141] S3011, photoetching a source electrode region and a drain electrode region on the GaN cap layer:

[0142] S3012, evaporating the source electrode and the drain electrode on the GaN cap layer in the source electrode region and the drain electrode re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com