Method for manufacturing heterojunction solar cell and heterojunction solar cell

A technology of solar cells and heterojunctions, which is applied in the manufacture of final products, sustainable manufacturing/processing, circuits, etc., can solve problems such as damage to amorphous silicon thin film layers, affect battery performance, and damage PN junction performance, and achieve improved Effects of open circuit voltage and fill factor, low carrier recombination rate, and good P-N junction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

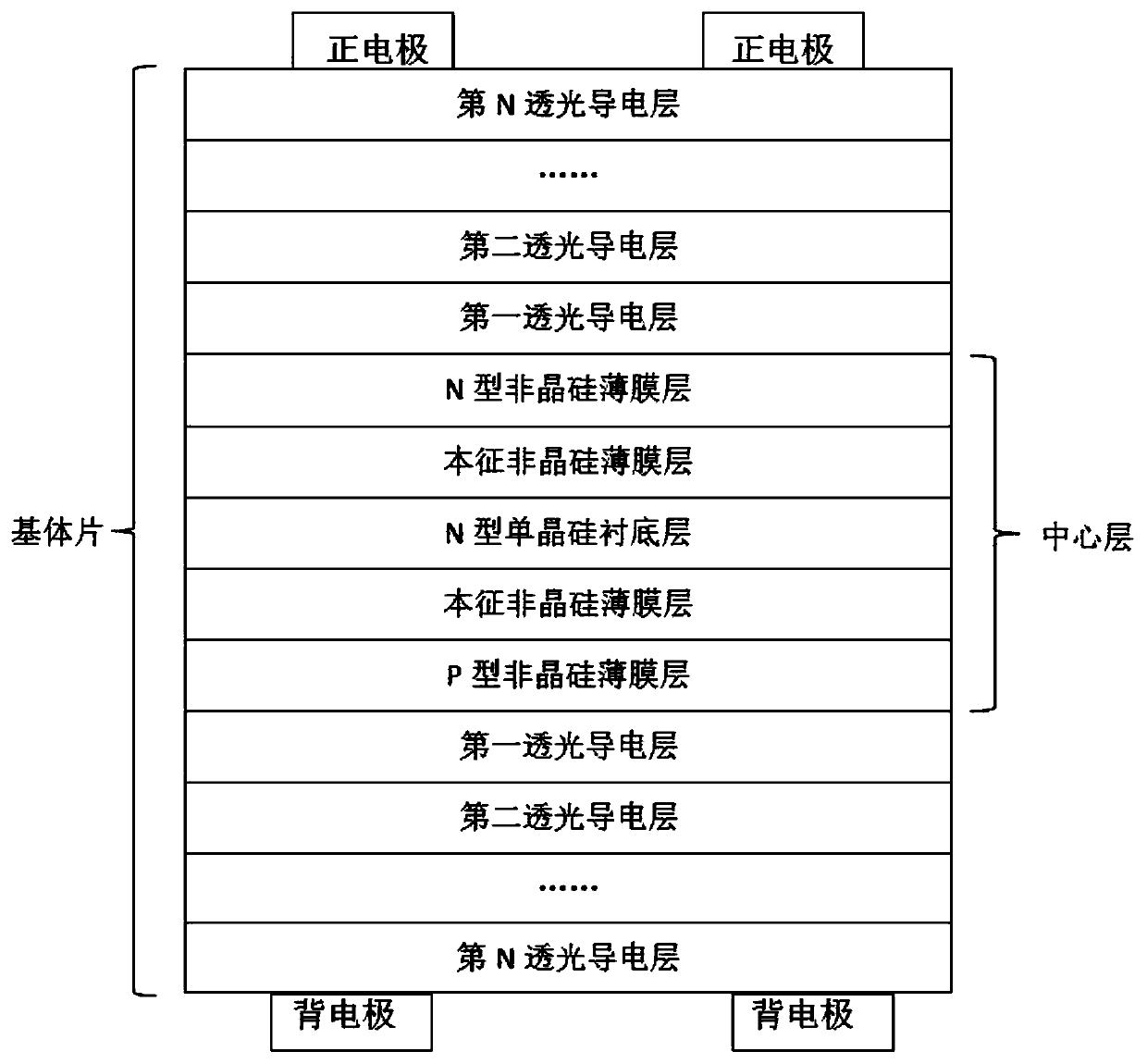

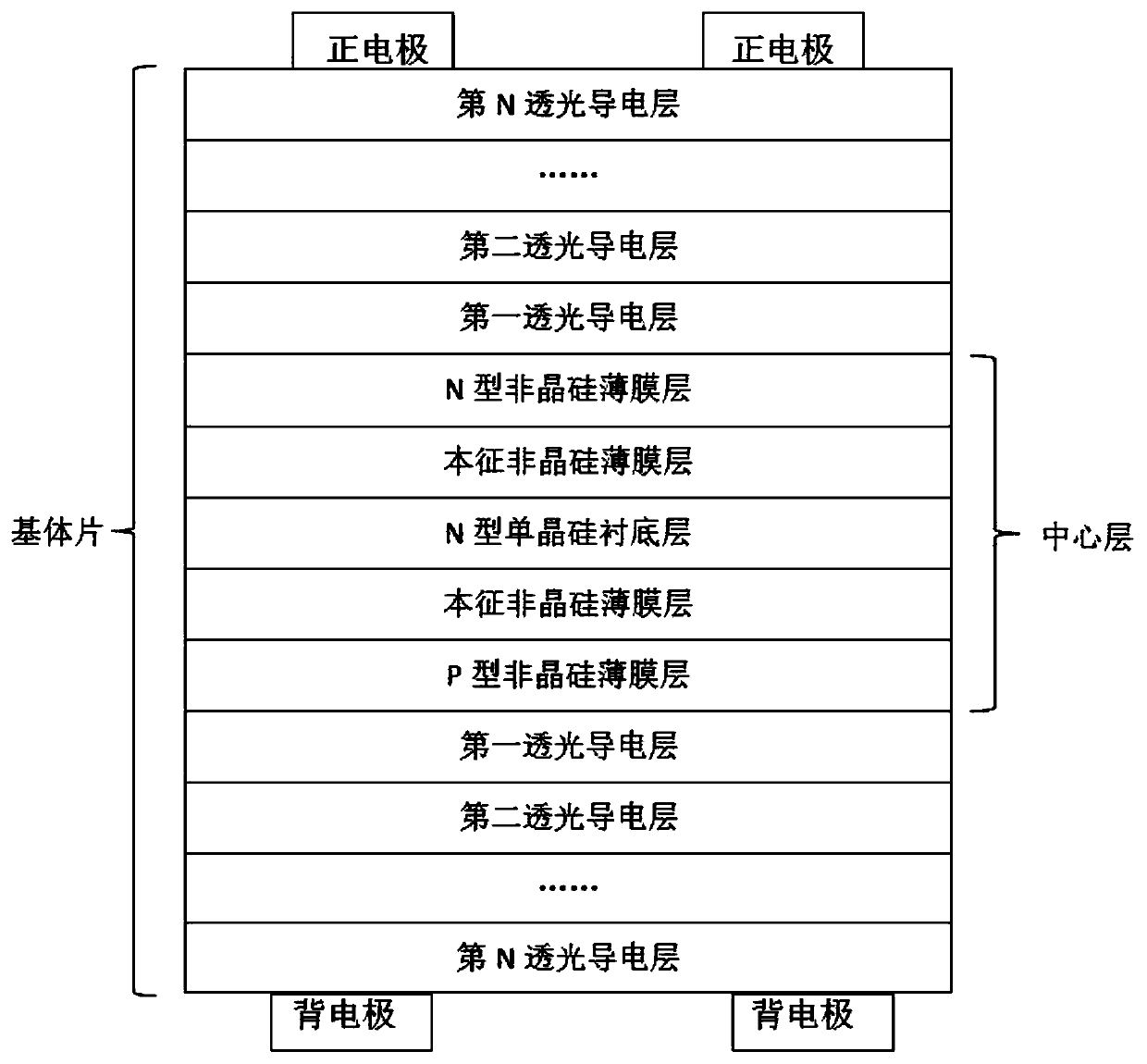

[0047] The present invention provides a method for manufacturing a heterojunction solar cell and a heterojunction solar cell. The following will provide a preferred embodiment of the present invention, which includes figure 1 The illustrated heterojunction solar cell and the method for manufacturing the heterojunction solar cell.

[0048] Such as figure 1 As shown, the heterojunction solar cell comprises a base sheet with a positive electrode printed on its top surface and a back electrode printed on its bottom surface, the positive and back electrodes being preferably made of silver. The base sheet further includes a plurality of cell layers stacked on each other along a direction perpendicular to the base sheet. The plurality of cell layers include a center layer and a plurality of light-transmitting conductive layers. The center layer is located at the center of all cell layers. The photoconductive layer is stacked on the top side and the bottom side of the central layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com