Large-particle passivation material with montmorillonite as substrate and preparation method and application thereof

A particle material and montmorillonite technology, applied in the field of large particle passivation materials and preparation, can solve the problem of poor operability and safety of alkaline passivation materials, affecting material operability and construction cost, and endangering the personal safety of construction personnel, etc. problems, to overcome poor operability and safety, reduce ecotoxicity, and improve sustained-release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Large montmorillonite particles, montmorillonite powder

[0036] making process:

[0037] 1. Large montmorillonite particles: Weigh 50 g of montmorillonite powder (purity ≥ 95%) in a centrifuge tube, add 50 g of water, and shake at 180 rpm at room temperature for 2 hours to fully mix the materials evenly. Dry the material in an oven at 75°C until the humidity is about 25%, put the viscous material into a syringe with a circular outlet diameter of 5mm, extrude it to obtain a strip of passivation material, and bake it at 350°C Dry to constant weight, then cut into cylindrical granular materials with a height of 5 mm and a cross-sectional diameter of 5 mm.

[0038] 2. Montmorillonite powder: montmorillonite powder with a purity ≥ 95%.

[0039] Application process:

[0040] 1. Material preparation: weigh 0.2g of each of the two materials, add Cd with a volume of 500mL and a concentration of 50mg / L 2+ Adsorption experiments were carried out in solution.

[0041] 2. Adso...

Embodiment 2

[0045] Comparison of cadmium passivation powder and particles at a mass ratio of 3:1

[0046] making process:

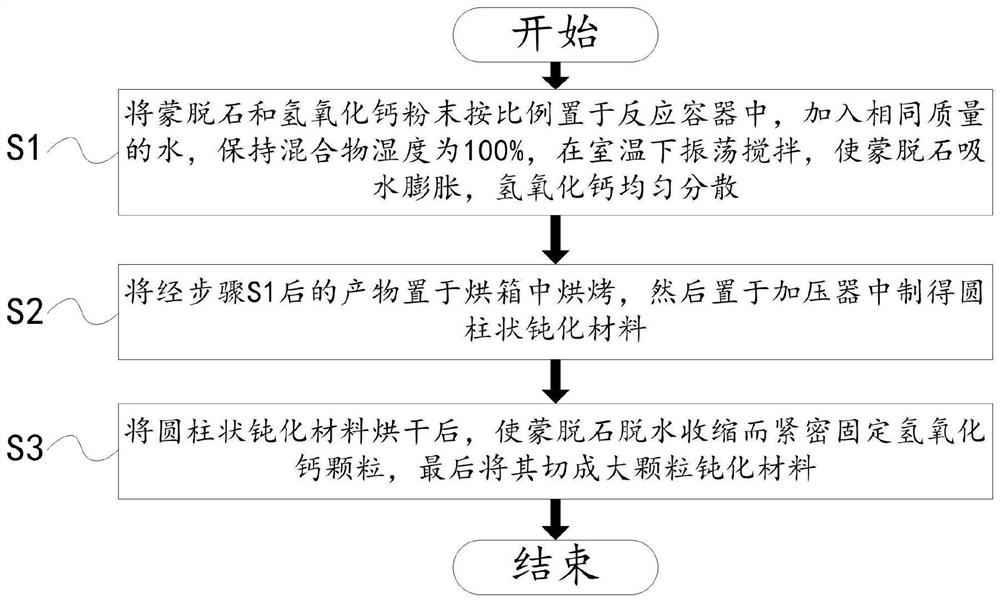

[0047] 1. Montmorillonite: Calcium Hydroxide = 3:1 large particles: Weigh 37.5g of montmorillonite powder (purity ≥ 95%) and 12.5g of calcium hydroxide powder (purity ≥ 95%) in a centrifuge tube, add 50g of water , shake at 180rpm at room temperature for 2 hours, so that the materials are fully mixed and even. Subsequent preparation process is with embodiment 1, as figure 1 shown.

[0048] 2. Montmorillonite: Calcium Hydroxide=3:1 powder: Take montmorillonite powder (purity ≥ 95%) 37.5g and calcium hydroxide powder (purity ≥ 95%) 12.5g in a centrifuge tube, at 180rpm rotating speed , Shake at room temperature for 2 hours, so that the materials are fully mixed, and can be taken directly for subsequent use.

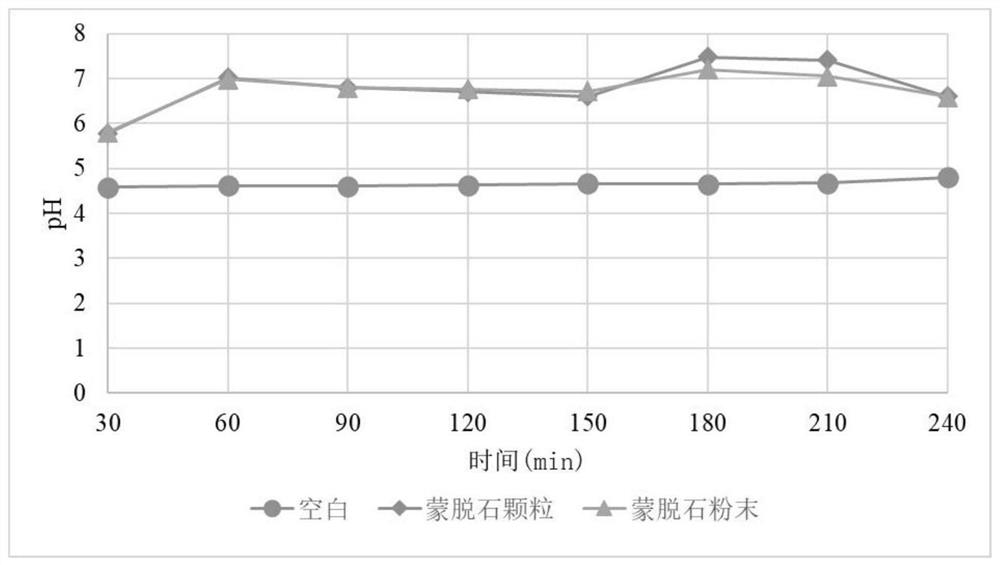

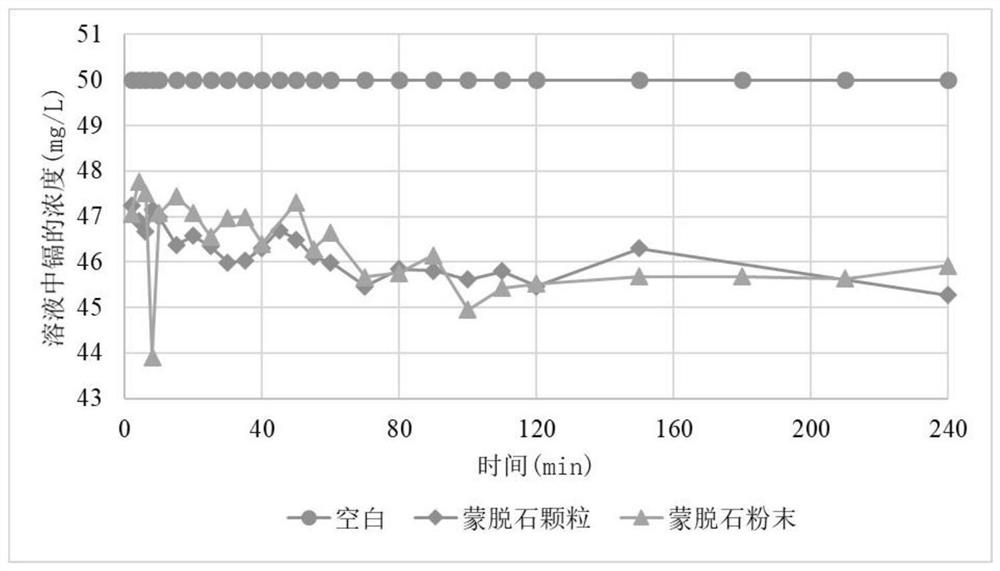

[0049] Application process: with embodiment 1. Test pH results see Figure 4 , sample Cd concentration see Figure 5 . The test results show that after ad...

Embodiment 3

[0051] making process:

[0052] 1. Montmorillonite: Calcium Hydroxide = 2:1 large particles: Weigh 33.33g of montmorillonite powder (purity ≥ 95%) and 16.67g of calcium hydroxide powder (purity ≥ 95%) in a centrifuge tube, add 50g of water , shake at 180rpm at room temperature for 2 hours, so that the materials are fully mixed and even. Subsequent preparation process is the same as in Example 1.

[0053] 2. Montmorillonite: Calcium Hydroxide=2:1 powder: Take by weighing montmorillonite powder (purity ≥ 95%) 33.33g and calcium hydroxide powder (purity ≥ 95%) 16.67g in centrifuge tube, at 180rpm rotating speed , Shake at room temperature for 2 hours, so that the materials are fully mixed, and can be taken directly for subsequent use.

[0054] Application process: with embodiment 1. Test pH results see Figure 6 , sample Cd concentration see Figure 7 . The test results show that after adding montmorillonite: calcium hydroxide=2:1 large particle and montmorillonite: calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com