A kind of method for improving the stability of vegetable protein beverage with high protein and high starch content

A vegetable protein beverage and high-starch technology, which is applied in the field of food processing, can solve the problems of not being suitable for industrial production, affecting production efficiency, and long hydrolysis process, etc., and achieve the effect of long storage time, low cost, and low production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

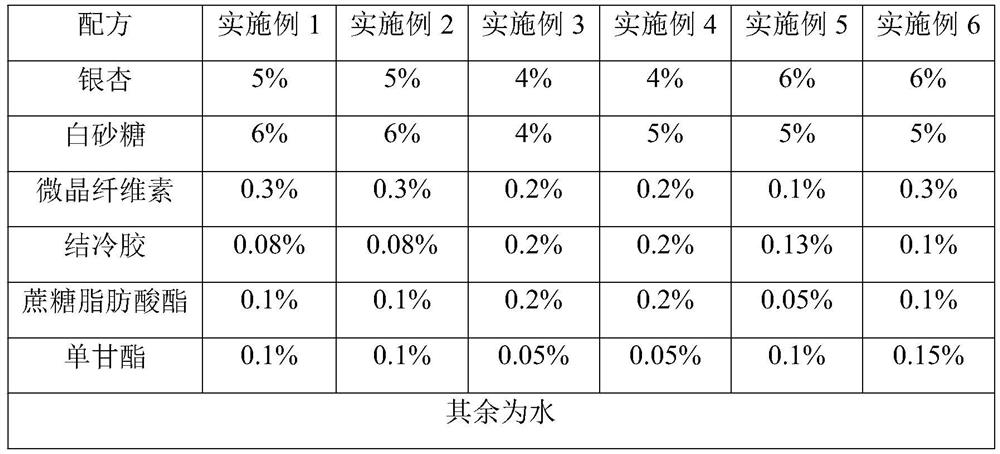

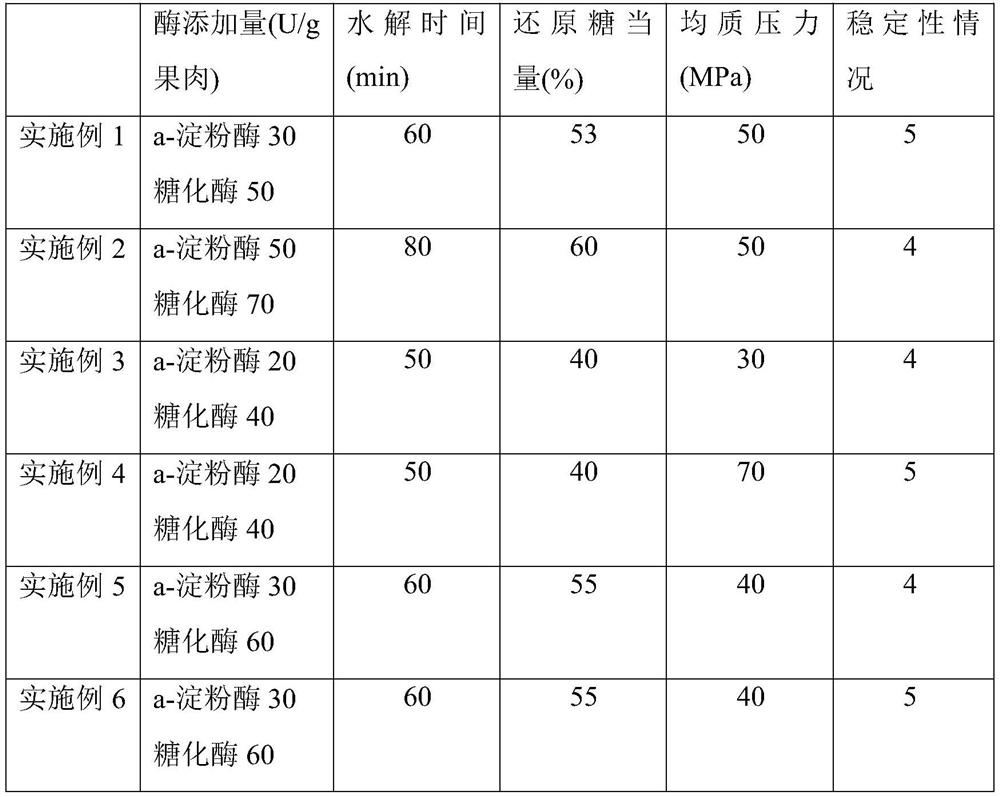

Embodiment 1

[0041] The method adopted in this embodiment is as follows:

[0042](1) Ginkgo pretreatment: select fresh, non-rotten ginkgo, rinse clean, shell and peel;

[0043] (2) Gelatinization: add 0.05% salt to water containing 0.05% sodium carbonate at 100°C, and gelatinize for 20 minutes to remove cyanogenic glycosides and part of ginkgolic acid;

[0044] (3) Colloid mill: smash the gelatinized ginkgo, then add an appropriate amount of warm water to make it pass through the colloid mill, and grind for 5 minutes;

[0045] (4) Enzymatic hydrolysis: add 30U / g pulp medium-temperature α-amylase and 50U / g pulp glucoamylase to the slurry formed by colloid mill, hydrolyze at 65°C for 60min, and measure the reducing sugar equivalent in the slurry to be 53 %;

[0046] (5) Enzyme inactivation: carry out enzymatic inactivation treatment on the hydrolyzed ginkgo turbid juice at 85°C for 15 minutes;

[0047] (6) Deployment: Add 0.3 part of microcrystalline cellulose to every 100 parts of cloudy...

Embodiment 2

[0052] The method adopted in this embodiment is as follows:

[0053] (1) Ginkgo pretreatment: select fresh, non-rotten ginkgo, rinse clean, shell and peel;

[0054] (2) Gelatinization: In water containing 0.1% sodium carbonate at 100°C, add 0.05% salt, gelatinize for 20 minutes, and remove cyanogenic glycosides and part of ginkgolic acid;

[0055] (3) Colloid mill: smash the gelatinized ginkgo, then add an appropriate amount of warm water to make it pass through the colloid mill, and grind for 5 minutes;

[0056] (4) Enzymatic hydrolysis: add 50U / g pulp medium-temperature α-amylase and 70U / g pulp glucoamylase to the slurry formed by the colloid mill, hydrolyze at 65°C for 80min, and measure the reducing sugar equivalent in the slurry to be 60 %;

[0057] (5) Enzyme inactivation: carry out enzymatic inactivation treatment on the hydrolyzed ginkgo turbid juice at 85°C for 15 minutes;

[0058] (6) Deployment: Add 0.3 part of microcrystalline cellulose to every 100 parts of clo...

Embodiment 3

[0063] The method adopted in this embodiment is as follows:

[0064] (1) Ginkgo pretreatment: select fresh, non-rotten ginkgo, rinse clean, shell and peel;

[0065] (2) Gelatinization: in water containing 0.05% sodium carbonate at 95°C, add 0.05% salt, gelatinize for 20 minutes, and remove cyanogenic glycosides and part of ginkgolic acid;

[0066] (3) Colloid mill: smash the gelatinized ginkgo, then add an appropriate amount of warm water to make it pass through the colloid mill, and grind for 5 minutes;

[0067] (4) Enzyme hydrolysis: add 20U / g pulp medium-temperature α-amylase and 40U / g pulp glucoamylase to the slurry formed by the colloid mill, hydrolyze at 65°C for 50min, measure the reducing sugar equivalent in the slurry at 40%;

[0068] (5) Enzyme inactivation: carry out enzymatic inactivation treatment on the hydrolyzed ginkgo turbid juice at 85°C for 15 minutes;

[0069] (6) deployment: add 0.2 part of microcrystalline cellulose to every 100 parts of cloudy juice b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com