Pickled beef sausages, and preparation method and preparation apparatus thereof

A beef sausage and beef technology, which is applied in the functions of food ingredients, food science, and application, can solve the problems of large differences in the source of casing raw materials, indigestion, and difficulty in automatic control, so as to avoid indigestion, remove fishy odor, and promote The effect of digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

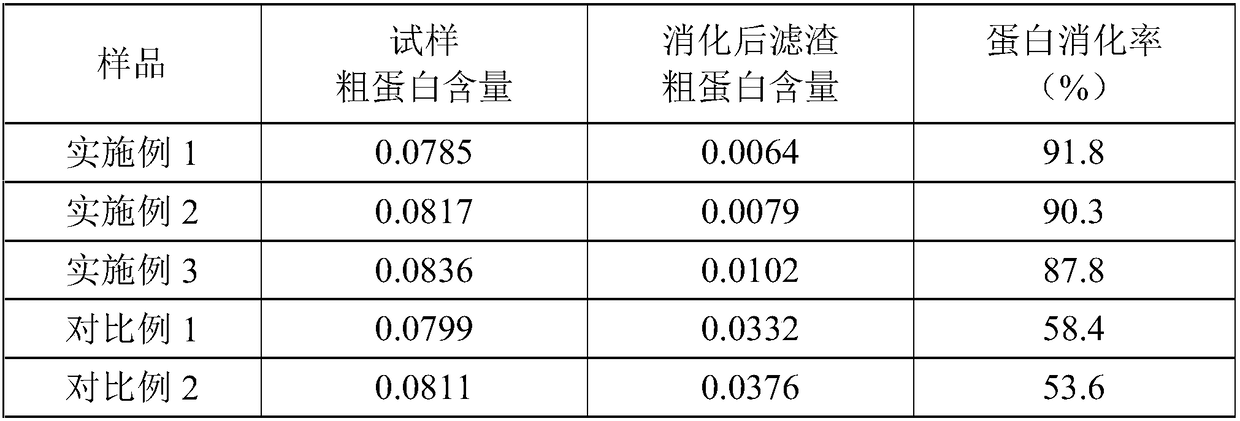

Embodiment 1

[0040] A marinated beef sausage is made from the following raw materials in parts by weight:

[0041] Beef 60; Corn Starch 8; Echinacea Powder 2.0; Olive Oil 4; Soy Protein Isolate 2; Yeast Extract 0.5; Onion Powder 1.2; Salt 6; White Sugar 1; Ginger Powder 0.4; Garlic Powder 0.5; Pepper Powder 0.2; Spice 0.1; Phosphate 0.3; Glutamine transaminase 0.05; D-isoascorbic acid 0.1.

[0042] The preparation method is as follows:

[0043] (1) Marinated beef: remove the bone and skin of the fresh beef and cut it into chunks with a thickness of 2cm, wash, soak, remove the surface dirt and drain; layer of salt, and neatly stacked in a 10°C curing box, take it out after 3 days, change the upper and lower positions of the meat, and add an appropriate amount of new salt, and then put it in a 10°C curing box to marinate for 14 days After marinating, the meat is taken out, and the meat is rinsed with 0.5% salt water for 4-6 times to obtain the marinated beef;

[0044] (2) Preparation of e...

Embodiment 2

[0052] A marinated beef sausage is made from the following raw materials in parts by weight:

[0053] Beef 70; Corn starch 10; Echinacea powder 2.2; Olive oil 5; Soy protein isolate 4; Yeast extract 0.6; Onion powder 1.5; Salt 7; White sugar 1.5; Ginger powder 0.5; Garlic powder 0.6; Pepper powder 0.3; Spices 0.15; Phosphate 0.4; Glutamine transaminase 0.06; D-isoascorbic acid 0.15.

[0054] The preparation method is the same as in Example 1.

Embodiment 3

[0056] A marinated beef sausage is made from the following raw materials in parts by weight:

[0057] Beef 80; Corn Starch 12; Echinacea Powder 2.4; Olive Oil 6; Soy Protein Isolate 5; Yeast Extract 0.8; Onion Powder 2.0; Salt 8; White Sugar 2; Ginger Powder 0.6; Garlic Powder 0.8; Pepper Powder 0.4; Spice 0.2; Phosphate 0.5; Glutamine transaminase 0.08; D-isoascorbic acid 0.2.

[0058] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com