Method for improving quality of low-salt-content fermented fish by utilizing staged temperature-controlled fermentation technology and product thereof

A technology for fermenting fish and stages, applied in the application field of biological fermentation technology in food processing, can solve the problems of long production cycle and large changes in product quality, and achieve the purpose of increasing aroma-enhancing ability, shortening fermentation cycle, and improving product sensory and quality. overall acceptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

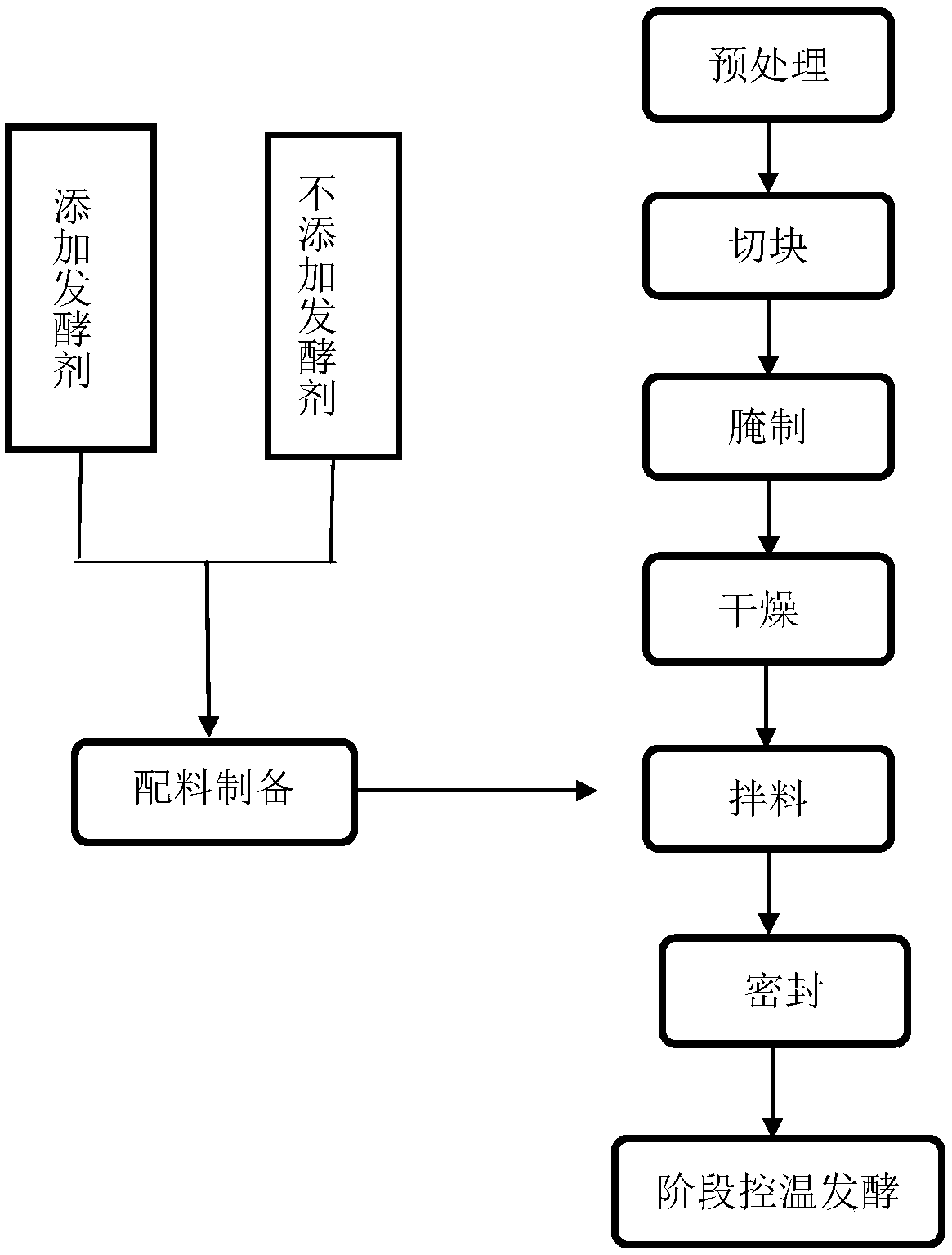

Method used

Image

Examples

Embodiment 1

[0033] Knock the head and kill the fresh carp, remove the head, tail, viscera, cut it from the back, remove the main bone spurs, wash the remaining viscera and blood congestion with clean water, and drain; cut the drained fish fillets into each piece weigh 20-30g, then add 3% salt and 2% white sugar by weight of the fish block, stir evenly, and marinate at 0-5°C for 2 days; put the pickled fish block at 50-60°C Blast dry for 1-3 hours, dry to 55-60% moisture content, cool to room temperature; take corn flour with 25% weight of fish meat, add 3% salt, 2% white sugar and appropriate amount of pepper, pepper, star anise and other spices, stir Evenly, stir-fry on low heat for 20-40 minutes, cool to room temperature, then add a small amount of cooled drinking water, mix evenly; fully mix the cooled fish pieces and processed corn flour ingredients; press one layer of fish and one layer of corn flour , compacted, airtight, and tightly sealed; fermented at 22-25°C for 7 days, and then...

Embodiment 2

[0035]Knock the head and kill the fresh carp, remove the head, tail, viscera, cut it from the back, remove the main bone spurs, wash the remaining viscera and blood congestion with clean water, and drain; cut the drained fish fillets into each piece weigh 20-30g, then add 3% salt and 2% white sugar by weight of the fish block, stir evenly, and marinate at 0-5°C for 2 days; put the pickled fish block at 50-60°C Blast drying for 1 to 3 hours, dry to a moisture content of 55 to 60%, and cool to room temperature; prepare a fermentation broth according to an inoculation amount of 1% of the weight of fish meat, and the added strains are Lactobacillus plantarum, Gluconococcus xylosus and Saccharomyces cerevisiae, the cells were collected by centrifugation after activation of the three, washed with normal saline, resuspended in normal saline respectively, and adjusted to a final concentration of 7-9 logcfu.g -1 , mixed according to the ratio of volume ratio 1:1:1 to obtain the strain ...

Embodiment 3

[0038] The stage fermentation temperature is controlled at 22-25 DEG C for 10 days of fermentation, then 18 days of fermentation at 30-32 DEG C for maturation, and other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com