Mineralized collagen-based moderate-strength artificial bone repair material and preparation method thereof

A technology of mineralized collagen and repair materials, applied in the field of bone materials, can solve the problems of inapplicability, low strength, and limited scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

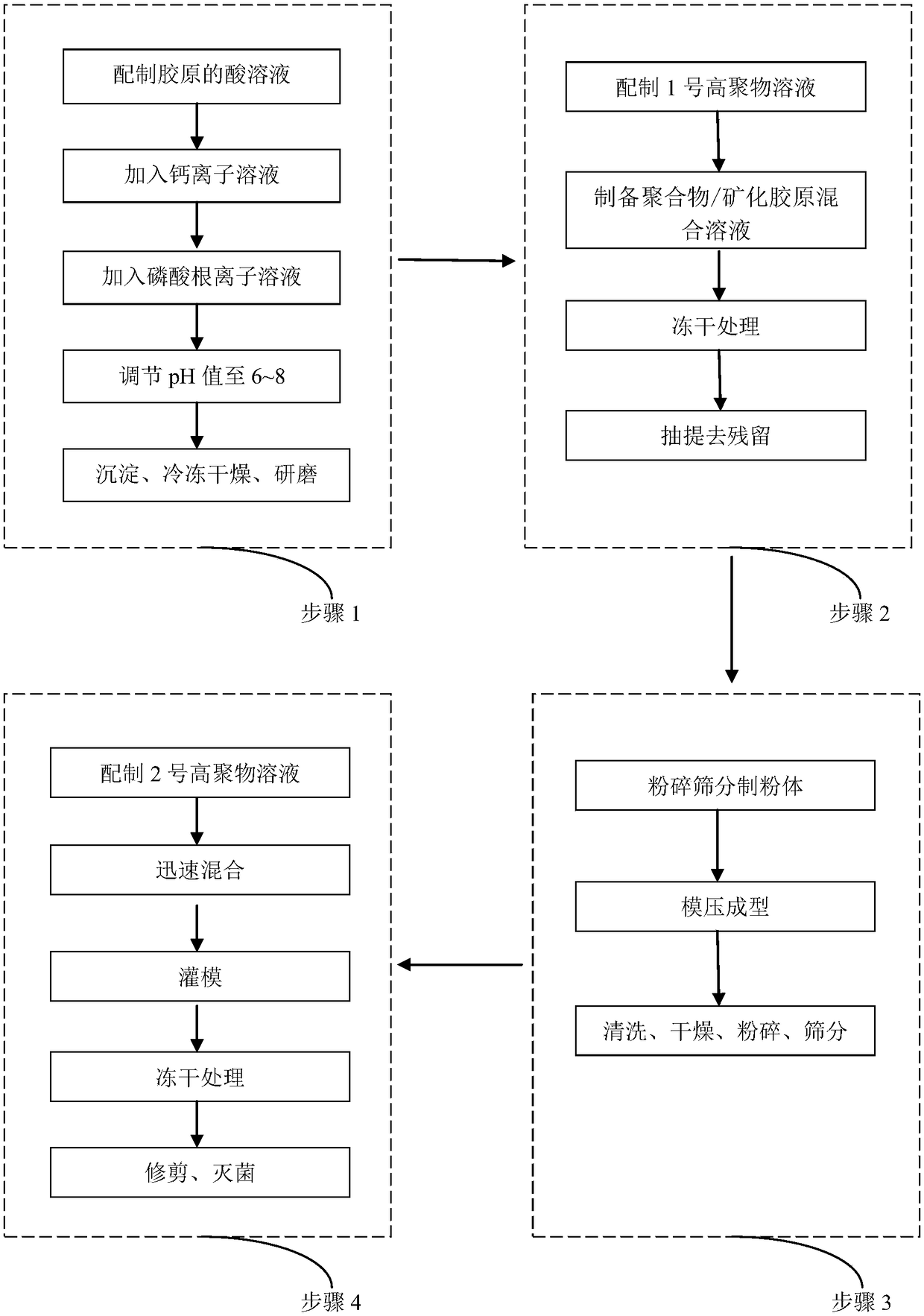

[0058] The invention provides a preparation method of a mineralized collagen-based medium-strength artificial bone repair material, the preparation method comprising:

[0059] (1) Preparation of polymer / mineralized collagen composites

[0060] The high molecular polymer is dissolved in an organic solvent, and the concentration is prepared to be 0.05-0.15g / mL (for example, it can be specifically 0.05g / mL, 0.08g / mL, 0.10g / mL, 0.12g / mL or 0.15g / mL mL) of the first high polymer solution and a concentration of 0.08 to 0.20 g / mL (for example, can be specifically 0.08 g / mL, 0.10 g / mL, 0.15 g / mL or 0.20 g / mL) of the second high polymer solution. The polymer used can be selected from polyε-caprolactone with a viscosity of 1.0 to 3.0dl / g, polylactic acid with a molecular weight of 100,000 to 300,000, and polylactic acid-glycolic acid copolymers with a molecular weight of 100,000 to 300,000. any of the things. The first high polymer solution and the second high polymer solution can be...

Embodiment 1

[0090] Such as figure 1 Shown, preparation method comprises the steps:

[0091] Step 1, the preparation of mineralized collagen dry powder specifically includes:

[0092] S1. Dissolving collagen in hydrochloric acid to prepare an acid solution of collagen, wherein the concentration of collagen is 0.5 mg / mL;

[0093] S2. Continue to stir the solution obtained in step S1, and slowly add the solution containing calcium ions dropwise. The amount of calcium ions added is 0.01 mol of calcium ions per gram of collagen;

[0094] S3, continue to stir the solution obtained in S2, slowly drop the solution containing phosphate ions, the molar ratio of the amount of phosphate ions added to the amount of calcium ions added in step S2 is Ca / P=1.5;

[0095] S4. Continue to stir the solution obtained in step S3, and slowly add NaOH solution dropwise until the pH of the mixed system is 6-8. When the pH=5-6, the mixed system begins to precipitate, and when the pH=7, the mixed system appears a ...

Embodiment 2

[0114] Preparation method is basically the same as Example 1, except that:

[0115] Use polylactic acid with a molecular weight of 100,000 to prepare the No. 1 polymer solution, and the mass volume concentration is 0.15g / mL;

[0116] Mineralized collagen dry powder and No. 1 high polymer solution are mixed according to the mass ratio of 1:1;

[0117] Use polylactic acid with a molecular weight of 300,000 to prepare a No. 2 polymer solution with a concentration of 0.20 g / mL;

[0118] The mixing ratio of No. 2 high polymer solution and hard polymer / mineralized collagen composite material particles is 4:3 by mass.

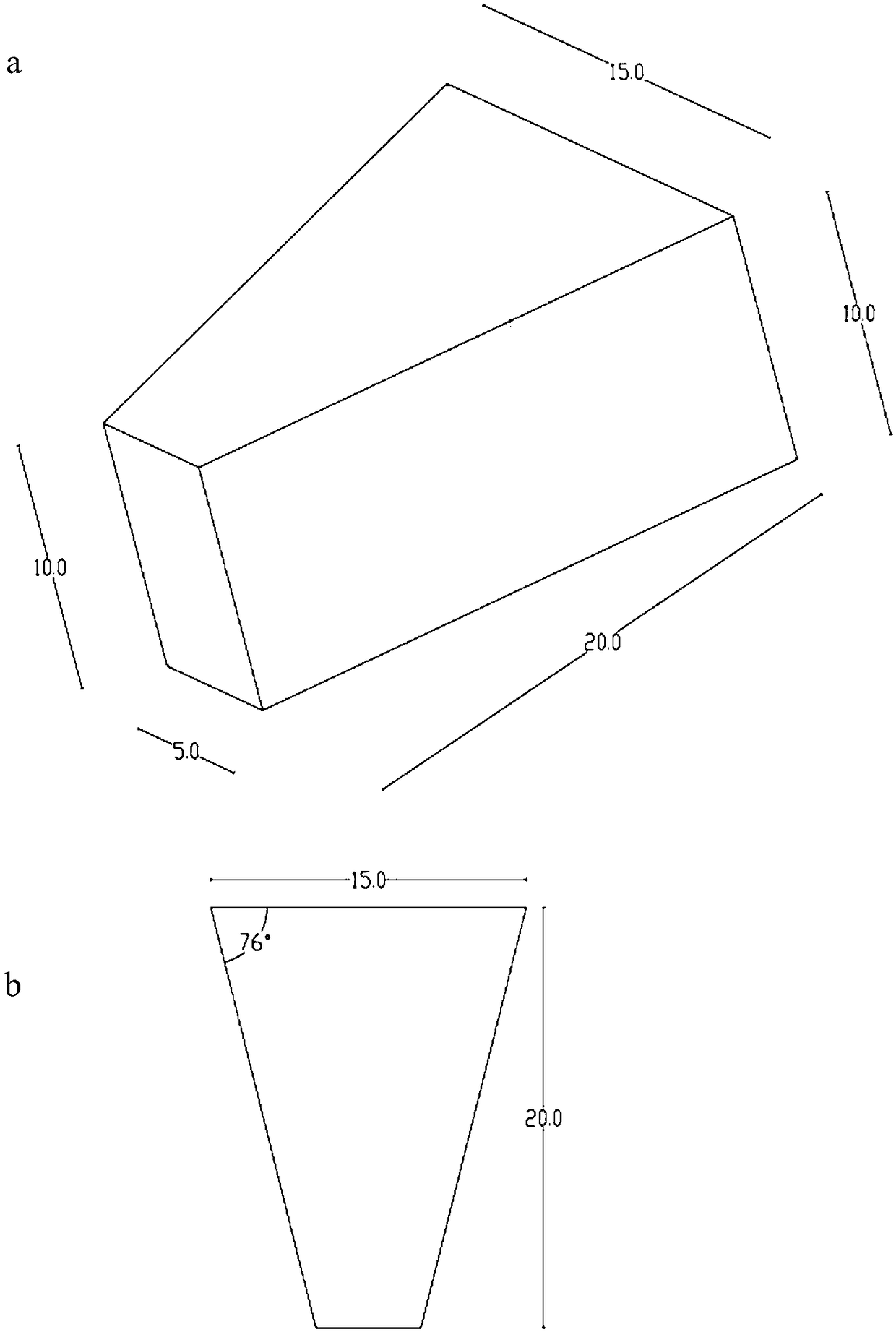

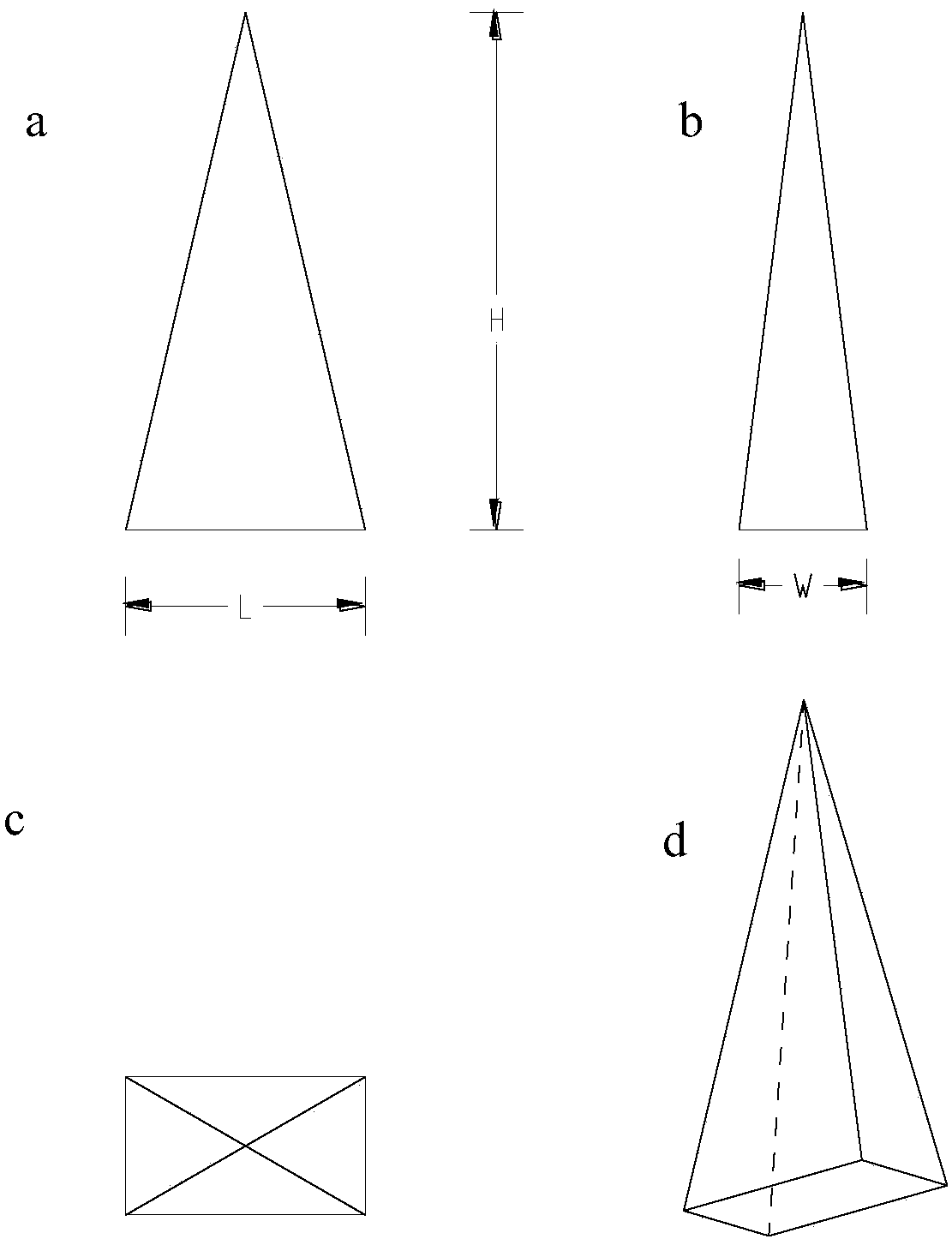

[0119] The shape of the final bone repair material is a wedge, such as image 3 shown.

[0120] It can be made into different models according to the needs, and the specific conditions of each model are shown in the table below.

[0121]

[0122] After testing, the bone repair material has a strength of 38MPa and a porosity of 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com