Explosion protection system and control method for scrap metal crushing machine

An explosion-proof system and crusher technology, used in grain processing and other directions, can solve problems such as endangering the life and health of operators, equipment damage, explosions, etc., to achieve accurate and reliable explosion-proof functions, reduce waste, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

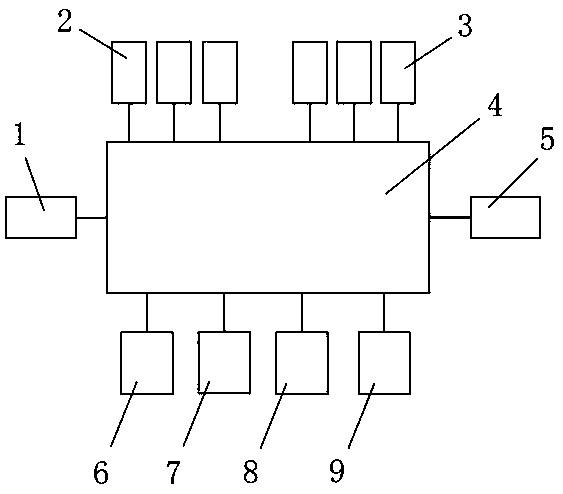

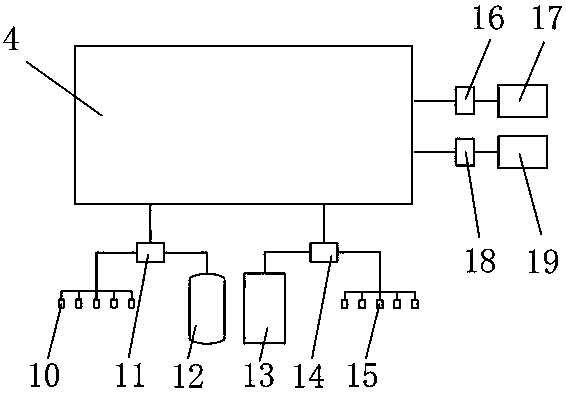

[0019] Such as figure 1 As shown, the present invention discloses an explosion-proof system and control method for a scrap metal shredder, including an oxygen concentration sensor 2, a gas pressure sensor 3, a nitrogen inerting device 6, a water mist explosion suppression device 7, an active explosion venting device 8, a dust removal Pipeline isolation device 9 and controller 4. The signal output end of the oxygen concentration sensor and the signal output end of the gas pressure sensor are respectively electrically connected to the signal receiving end of the controller 4; the signal output end of the controller 4 is connected to the nitrogen inerting device 6 , Water mist explosion suppression device 7, dust removal pipeline isolation device 9, and active explosion venting device 8 are electrically connected.

[0020] In the above embodiments, for the explosion-proof system of the scrap metal crusher, different explosion-proof measures are taken for the situation that the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com