Method for preparing hydroxyethyl cellulose

A technology of hydroxyethyl cellulose and alkali cellulose, applied in the field of cellulose, to achieve high viscosity, improve construction efficiency, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

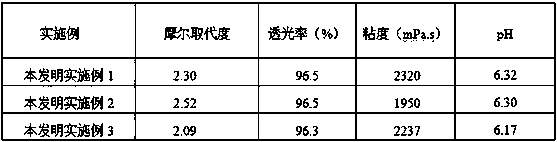

Examples

Embodiment 1

[0041] Example 1 A method for preparing hydroxyethyl cellulose includes the following preparation steps:

[0042] (1) Preparation of alkali cellulose

[0043] Add 7 parts by mass of isopropanol and 1.05 parts by mass of water into the reactor, then add 0.28 parts by mass of sodium hydroxide, mix well and add 1 part by mass of pulverized pulp with degree of polymerization ≥1000, nitrogen atmosphere The alkalization is carried out under the control of 25℃ for alkalization temperature and 25min for alkalization time to swell the cellulose.

[0044] (2) Primary cellulose etherification

[0045] The alkali cellulose prepared in step (1) was added to 0.38 parts by mass of ethylene oxide, and then the temperature was raised to 60° C. to perform etherification of the cellulose once, and the etherification time was 70 min.

[0046] (3) Secondary etherification

[0047] After the primary cellulose etherification, the material is cooled to 30°C, 0.3 parts by mass of acetic acid is added to the mat...

Embodiment 2

[0050] Example 2 A preparation method of hydroxyethyl cellulose includes the following preparation steps:

[0051] 1) Preparation of alkali cellulose

[0052] Add 6.1 parts by mass of isopropanol, 0.5 parts by mass of ethanol, and 0.9 parts by mass of water into the reaction kettle, then add 0.3 parts by mass of sodium hydroxide, mix well and add 1 part by mass of pulverized polymerization degree ≥ 1000 pulp, alkalization under nitrogen atmosphere, alkalization temperature is controlled at 35℃, alkalization time is controlled at 35min, so that cellulose swells.

[0053] (2) Primary cellulose etherification

[0054] The alkali cellulose prepared in step (1) was added to 0.42 parts by mass of ethylene oxide, and then the temperature was raised to 60° C. to perform etherification of the cellulose once, and the etherification time was 85 minutes.

[0055] (3) Secondary etherification

[0056] After the first cellulose etherification, the material is cooled to 30°C, 0.33 parts by mass of ace...

Embodiment 3

[0059] Example 3 A preparation method of hydroxyethyl cellulose includes the following preparation steps:

[0060] 1) Preparation of alkali cellulose

[0061] Add 7 parts by mass of ethanol, 0.11 parts by mass of water into the reactor, and then add 0.29 parts by mass of sodium hydroxide, mix well and add 1 part by mass of pulverized pulp with a degree of polymerization of ≥1000, and alkali in a nitrogen atmosphere The alkalization temperature is controlled at 35℃, and the alkalization time is controlled at 50min to swell the cellulose.

[0062] (2) Primary cellulose etherification

[0063] The alkali cellulose prepared in step (1) was added to 0.3 parts by mass of ethylene oxide, and then the temperature was raised to 70° C. for a cellulose etherification, and the etherification time was 100 min.

[0064] (3) Secondary etherification

[0065] After the primary cellulose etherification is completed, the material is cooled to 40°C, 0.27 parts by mass of sulfuric acid is added to the mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com