Flame retardant bio-based polyester and preparation method thereof

A polyester-based and bio-based technology, applied in the field of flame-retardant materials, can solve the problems of uneven dispersion of graphene substrates, affecting the flame-retardant effect of materials, and easy melting and dripping, so as to achieve the suppression of candle wick effect and flame-retardant efficiency High, improve the effect of melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

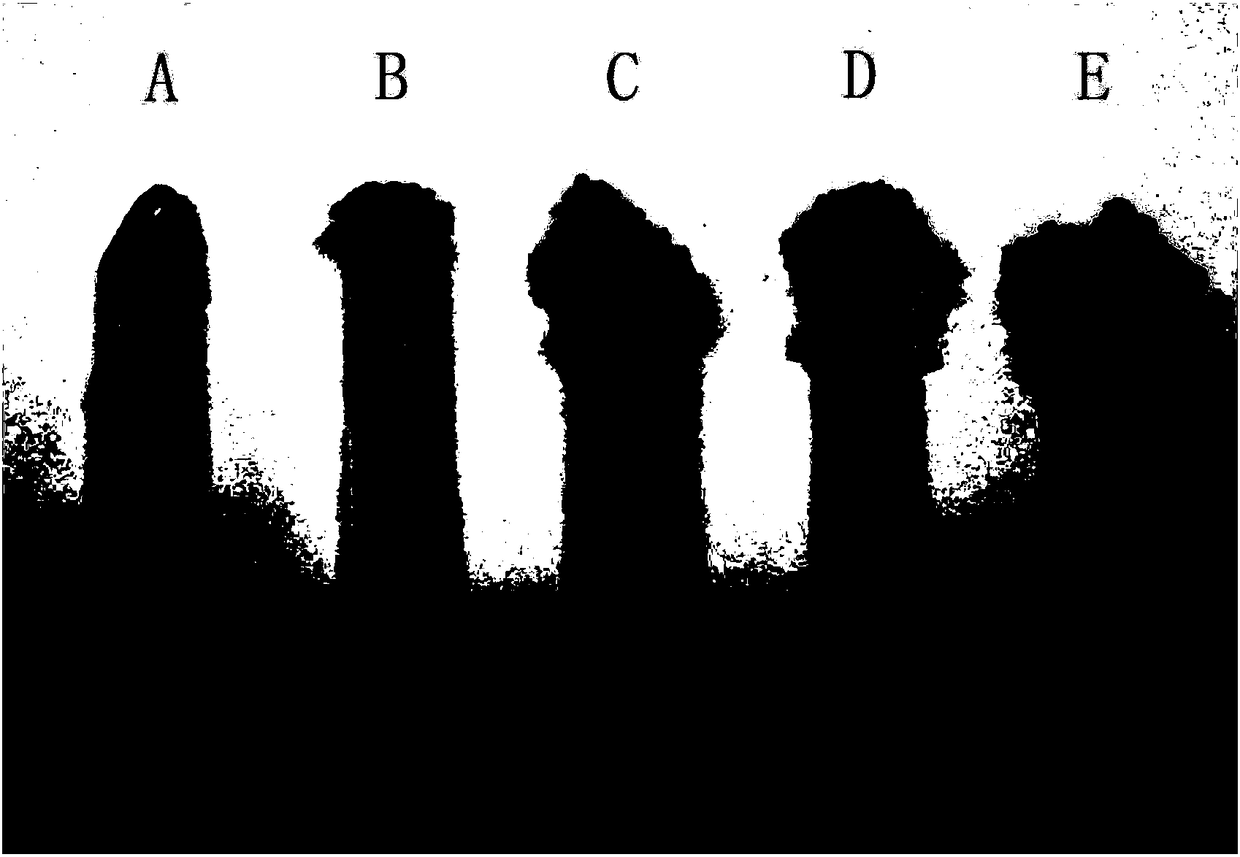

Image

Examples

Embodiment 1

[0027] Preparation of a Flame Retardant Bio-Based Polyester

[0028] (1) Disperse 0.45g of aminated carbon nanotubes in 0.45L of N,N-dimethylformamide solution, and ultrasonicate for 20min at 100W to obtain a carbon nanotube dispersion, wherein N,N-dimethylformamide The volume ratio of N,N-dimethylformamide and water in the amide solution is 2:1;

[0029] (2) Disperse 4.5g of ammonium polyphosphate with a degree of polymerization greater than 1000 and in the form of white powder in 0.45L of deionized water, and ultrasonicate for 30min at 100W to prepare an ammonium polyphosphate dispersion;

[0030] (3) the ammonium polyphosphate dispersion liquid prepared in step (2) is added dropwise in the carbon nanotube dispersion liquid prepared in step (1) by the speed of 10mL / min, wash with water and ethanol alternately after mixing, Each was washed 3 times, and dried at 60°C for 6 hours after suction filtration to obtain a carbon nanotube flame retardant;

[0031] (4) 100 parts of p...

Embodiment 2

[0033] Preparation of a Flame Retardant Bio-Based Polyester

[0034] (1) Disperse 0.45g of aminated carbon nanotubes in 22.5L of N,N-dimethylformamide solution, and ultrasonicate for 20min at 100W to obtain a carbon nanotube dispersion, wherein N,N-dimethylformamide The volume ratio of N,N-dimethylformamide and water in the amide solution is 2:1;

[0035] (2) Disperse 4.5g of ammonium polyphosphate with a degree of polymerization greater than 1000 and in the form of white powder in 0.18L of deionized water, and ultrasonicate for 30min at 100W to prepare an ammonium polyphosphate dispersion;

[0036] (3) the ammonium polyphosphate dispersion liquid prepared in step (2) is added dropwise in the carbon nanotube dispersion liquid prepared in step (1) by the speed of 1mL / min, wash with water and ethanol alternately after mixing, Each was washed twice, and dried at 70°C for 4 hours after suction filtration to obtain a carbon nanotube flame retardant;

[0037] (4) After mixing 100 ...

Embodiment 3

[0039] Preparation of a Flame Retardant Bio-Based Polyester

[0040] (1) Disperse 0.45g of aminated carbon nanotubes in 45L of N,N-dimethylformamide solution, and ultrasonicate for 20min at 100W to obtain a carbon nanotube dispersion, wherein N,N-dimethylformamide The volume ratio of N,N-dimethylformamide and water in the solution is 2:1;

[0041] (2) Disperse 4.5g of ammonium polyphosphate with a degree of polymerization greater than 1000 and in the form of white powder in 0.09L of deionized water, and ultrasonicate for 30min at 100W to prepare an ammonium polyphosphate dispersion;

[0042] (3) the ammonium polyphosphate dispersion liquid prepared in step (2) is added dropwise in the carbon nanotube dispersion liquid prepared in step (1) by the speed of 5mL / min, wash with water and ethanol alternately after mixing, Each was washed 3 times, and dried at 80°C for 2 hours after suction filtration to obtain a carbon nanotube flame retardant;

[0043] (4) After mixing 100 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com