Method for treating aquaculture wastewater through immobilized chlorella

A technology for immobilizing small balls and aquaculture wastewater, applied to chemical instruments and methods, fixed on/in organic carriers, non-polluting water treatment, etc., can solve problems such as large footprint, poor mechanical strength, and difficulty in separation problems, achieve good nitrogen and phosphorus removal effects, reduce costs, and avoid toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Sodium alginate, agar and PVA three immobilized materials to the situation of denitrification and dephosphorization of aquaculture wastewater

[0054] Sodium alginate (Alginate), agar (Agar) and PVA are three immobilized materials to embed Chlorella, and the method is shown in 2. Put the immobilized chlorella made of equal volumes of 2% sodium alginate, agar and PVA algae liquid mixture into 500mL aquaculture wastewater respectively, and place the Erlenmeyer flask in a constant temperature light incubator. The culture conditions are 25°C, 4000 lux light, and 12h:12h light-to-dark ratio. Shake the Erlenmeyer flask 5 times a day and take samples regularly.

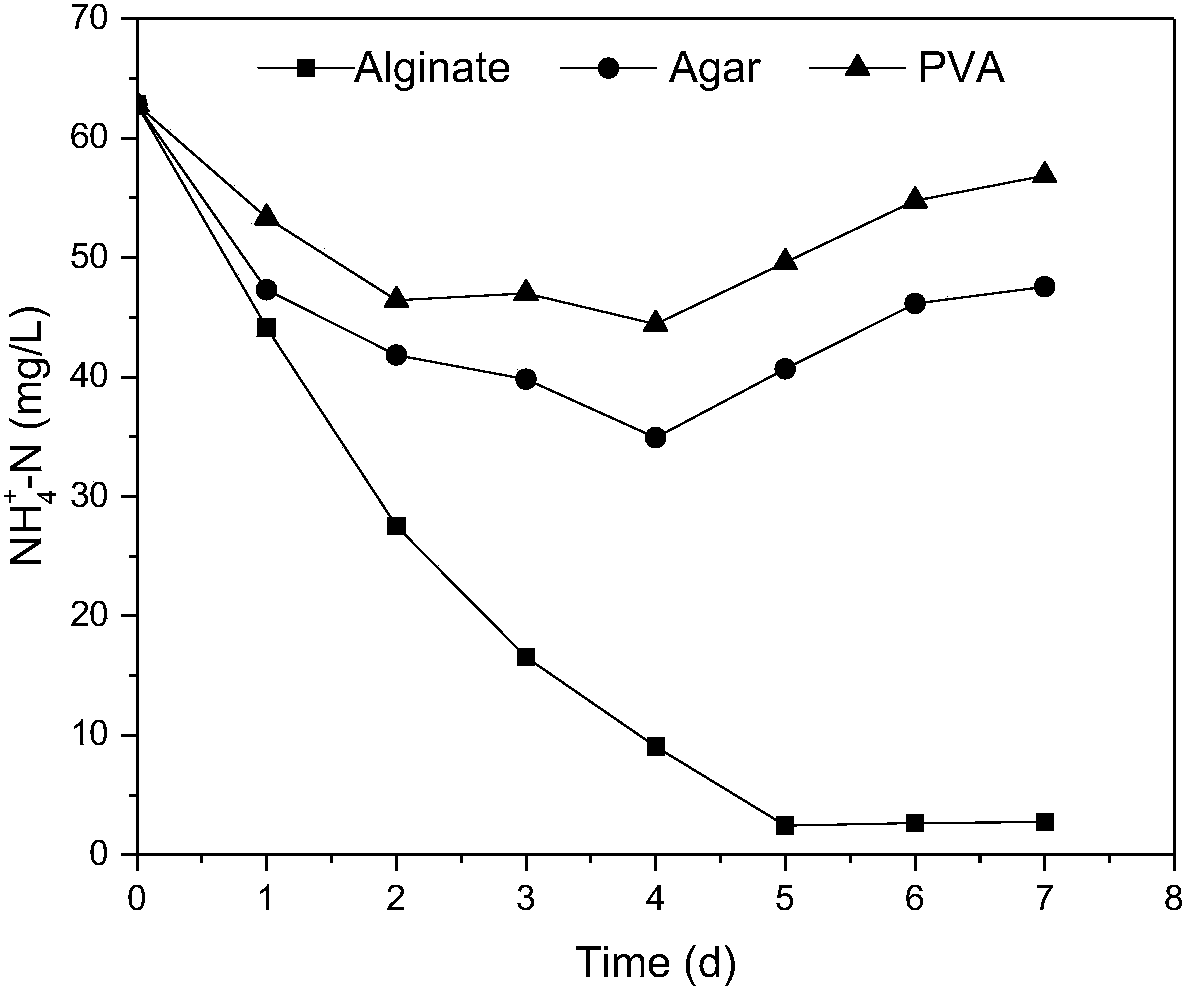

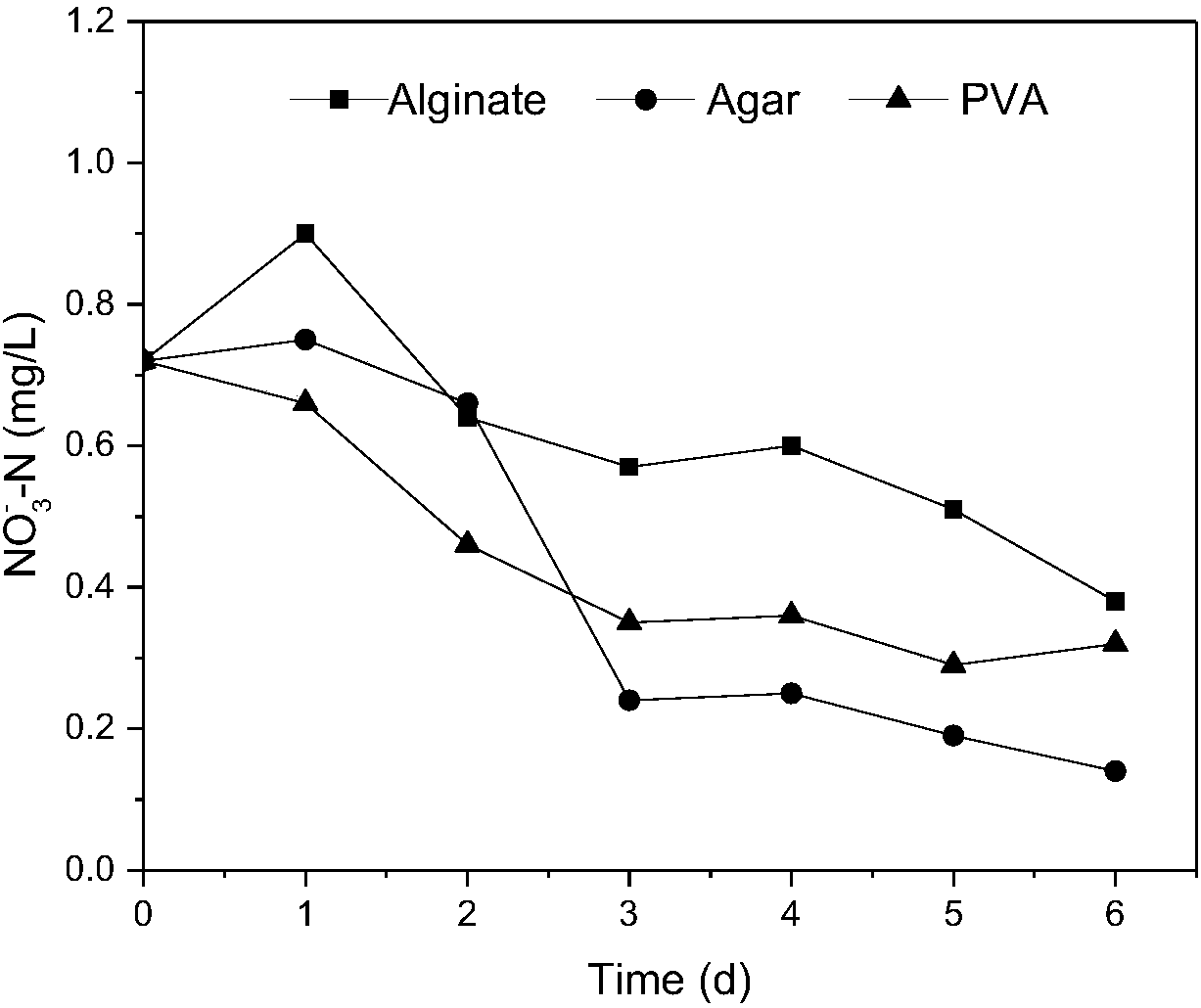

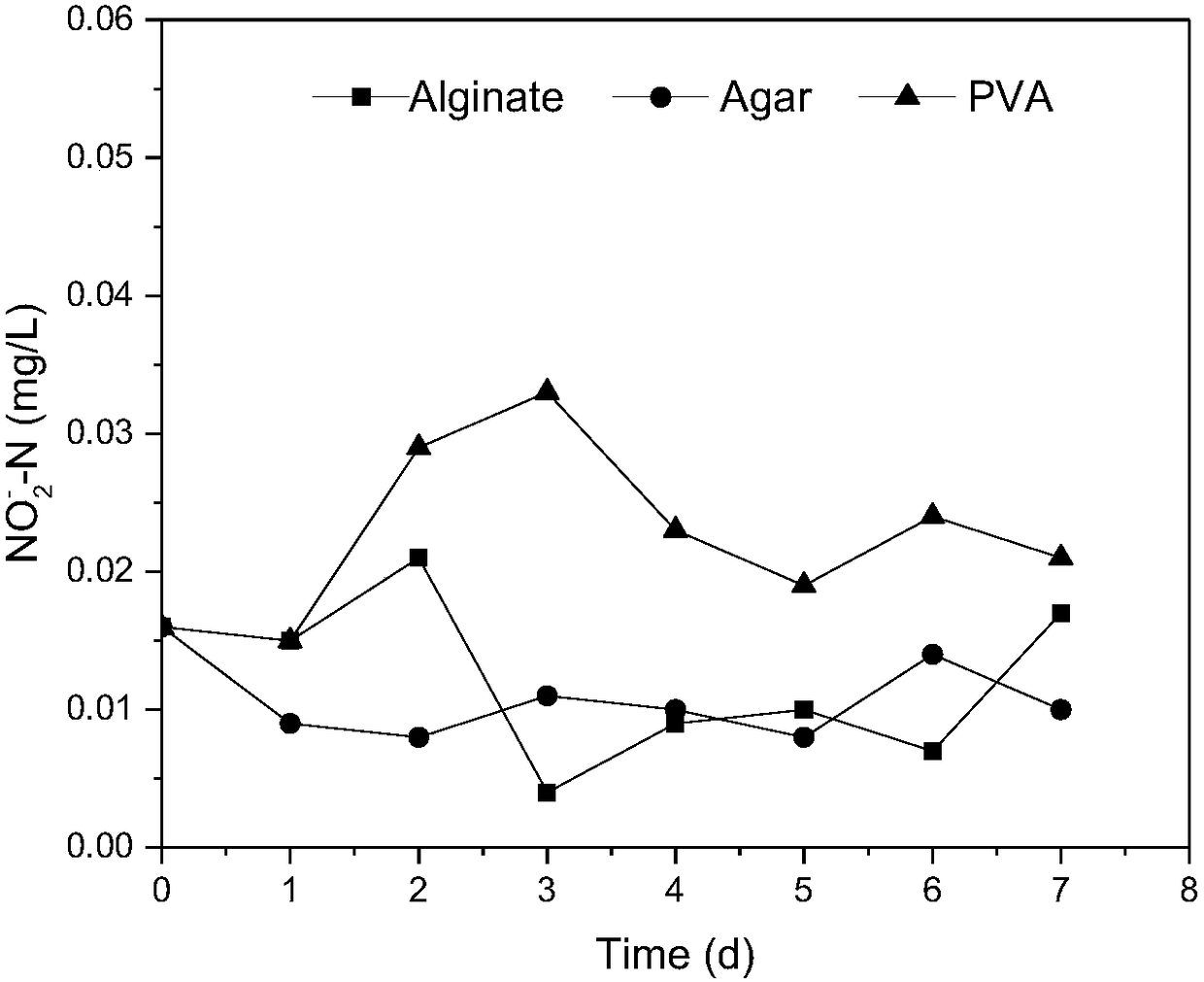

[0055] Determination of NH in water samples 4 + -N, NO 3 - -N, NO 2 - -N, TN and TP. figure 1 , Sodium alginate, agar and PVA immobilized materials on the NH of aquaculture wastewater 4 + -N Remove case. The three kinds of immobilized chlorella have a certain removal effect on ammonia nitrogen in...

Embodiment 2

[0060] Embodiment 2: The situation of denitrification and dephosphorization of aquaculture wastewater by immobilized chlorella and free chlorella

[0061] Centrifuge the chlorella solution cultivated to the logarithmic phase at 4000r / min for 5 minutes, wash with deionized water three times and then centrifuge, take an appropriate volume of microalgae solution and add it to 500mL aquaculture wastewater, adjust the algae density (OD) to about 0.3, and then Take an equal volume of algae liquid and use the above-mentioned 2 immobilization methods to embed the chlorella with 2% sodium alginate to make immobilized chlorella. In addition, set a blank water sample group and a blank immobilized ball group. Place the Erlenmeyer flask in a constant temperature light incubator. The culture conditions are 25°C, 4000 lux light, and 12h:12h light-to-dark ratio. Shake the Erlenmeyer flask 5 times a day and take samples regularly.

[0062] Determination of NH in water samples 4 + -N, NO ...

Embodiment 3

[0066] Example 3: The situation of nitrogen and phosphorus removal from aquaculture wastewater with different sodium alginate contents

[0067] Centrifuge the chlorella liquid cultured to the logarithmic phase at 4000r / min for 5 minutes, wash with deionized water three times and then centrifuge, and use sodium alginate solutions with concentrations of 1%, 2%, 3%, and 4% according to the method in 2 Made into immobilized pellets. Immobilized chlorella with different concentrations of sodium alginate were put into 500 mL of aquaculture wastewater (labeled 1%, 2%, 3%, 4%) respectively, and the Erlenmeyer flasks were placed in a constant temperature light incubator. The culture conditions are 25°C, 4000 lux light, and 12h:12h light-to-dark ratio. Shake the Erlenmeyer flask 5 times a day and take samples regularly.

[0068] Determination of NH in water samples 4 + -N, NO 3 - -N, TN and TP. Figure 10 , the effect of different sodium alginate contents on the NH of aquaculture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com