Porous amino-functionalized graphene catalytic material and preparation and application

A graphene catalytic material and amino-functional technology, applied in the field of electrochemical materials, can solve the problems of low electrocatalytic activity, high hydrogen evolution potential of electrolysis electrodes, high price, etc., and achieve the improvement of active sites and conductivity, and low synthesis cost. , the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

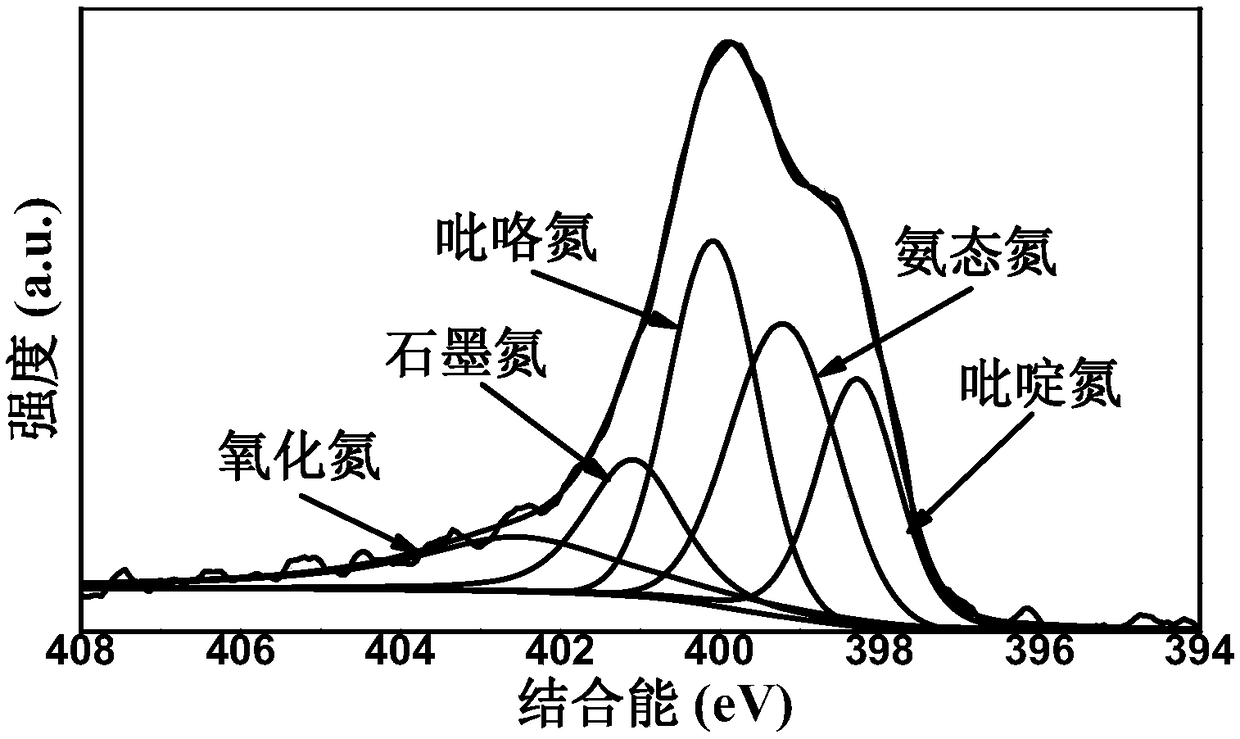

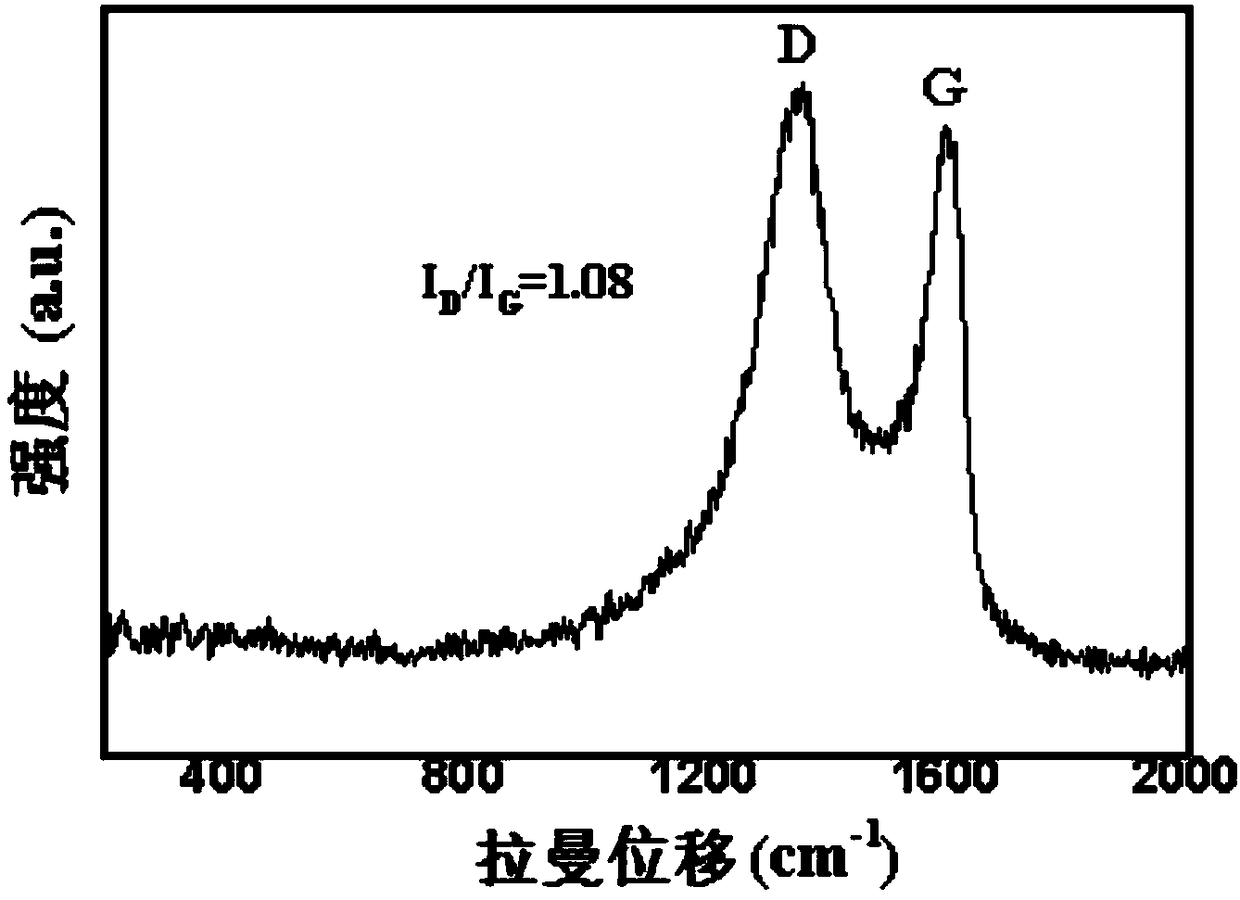

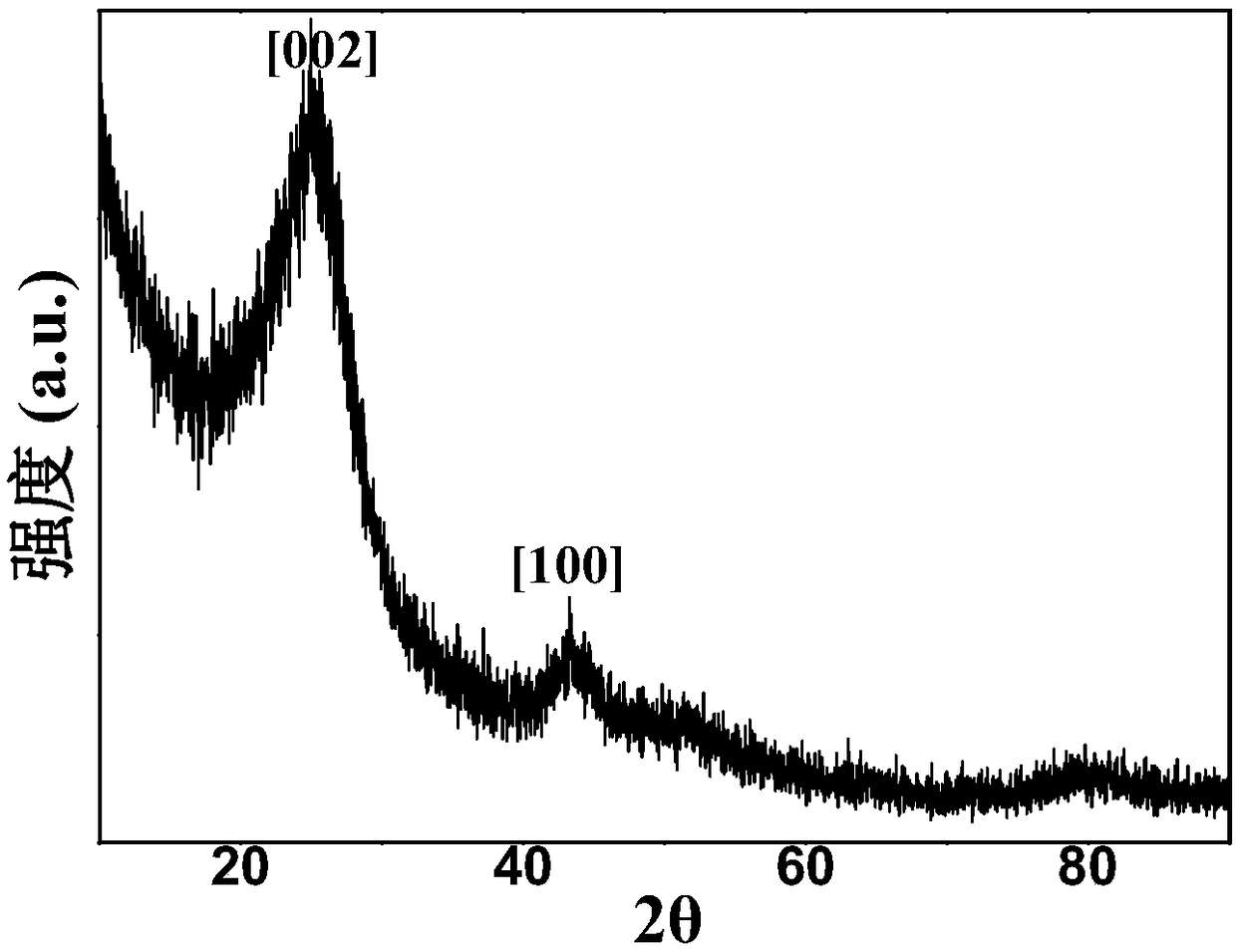

[0037] (1) Measure 100 mg of graphene oxide gel and dissolve it in 40 mL of deionized water. After ultrasonic stirring at room temperature for 30 min, a uniformly mixed solution is obtained. Then add 2 mL of ammonia water and stir at room temperature for 30 min. Transfer to a 50mL reactor, and conduct a hydrothermal reaction at 180°C for 12h. The hydrothermal reaction product was centrifuged, washed with water for 5 times, and then dried in a vacuum freeze-drying oven for 24 hours to obtain amino-functionalized graphene (AFNG).

[0038] (2) Weigh 20 mg of amino-functionalized graphene and disperse it in 80 mL of 6M KOH solution, heat to 80 ° C, and stir and erode for 12 h, then transfer the above solution to a polytetrafluoroethylene ball mill tank, and ball mill at a speed of 400 rpm 30h, the obtained black solution was first washed with 1M HCl to neutrality, and finally centrifuged, washed 5 times with water, and then dried in a vacuum freeze-drying oven for 24h to obtain a ...

Embodiment 2

[0043] (1) Measure 100 mg of graphene oxide gel and dissolve it in 40 mL of deionized water. After ultrasonic stirring at room temperature for 30 min, a uniformly mixed solution is obtained. Then add 4 mL of ammonia water and stir at room temperature for 30 min. Transfer to a 50mL reactor, and perform hydrothermal reaction at 150°C for 10h. The hydrothermal reaction product was centrifuged, washed with water three times, and then dried in a vacuum freeze-drying oven for 48 hours to obtain amino-functionalized graphene (AFNG).

[0044] (2) Weigh 15 mg of amino-functionalized graphene and dissolve it in 80 mL of 6M KOH solution, heat to 100 ° C, and stir and erode for 24 h, then transfer the above solution to a polytetrafluoroethylene ball mill tank, and ball mill at a speed of 1100 rpm 60h, the obtained black solution was first washed with 1M HCl to neutrality, and finally centrifuged, washed 5 times with water, and then dried in a vacuum freeze-drying oven for 24h to obtain a ...

Embodiment 3

[0048] (1) Measure 100 mg of graphene oxide gel and dissolve it in 40 mL of deionized water. After ultrasonic stirring at room temperature for 30 min, a uniformly mixed solution is obtained. Then add 2 mL of ammonia water and stir at room temperature for 30 min. Transfer to a 50mL reactor, and conduct a hydrothermal reaction at 200°C for 15h. The hydrothermal reaction product was centrifuged, washed with water for 5 times, and then dried in a vacuum freeze-drying oven for 24 hours to obtain amino-functionalized graphene (AFNG).

[0049] (2) Dissolve 10 mg of amino-functionalized graphene in 80 mL of 10M KOH solution, heat to 90 ° C, and stir and erode for 12 h, then transfer the above solution to a polytetrafluoroethylene ball mill tank, and ball mill at a speed of 900 rpm 45h, the obtained black solution was first washed with 1M HCl to neutrality, and finally centrifuged, washed 5 times with water, and then dried in a vacuum freeze-drying oven for 36h to obtain a porous amino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com