Chromium-doped calcium aluminum niobate tunable laser crystal and preparation method thereof

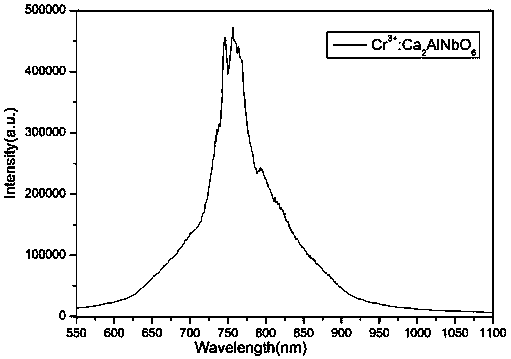

A laser crystal and niobic acid technology, applied in the field of materials science, can solve the problems of tunable wavelength range, poor absorption coefficient performance, etc., and achieve the effects of high emission intensity, good physical and chemical properties, and stable growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

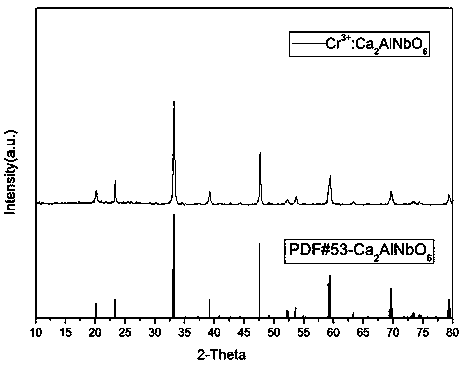

[0028] Preparation of Cr by High Temperature Solid Phase Method 3+ : Ca 2 AlNbO 6 (Cr 3+ The doping concentration is 0.3at.%), and the raw material used is analytically pure Al 2 o 3 , CaCO 3 , Nb 2 o 5 and Cr 2 o 3 . Then weigh the materials according to the proportion of the following chemical reaction formula, grind and mix them evenly with an agate mortar, put them into a 50×50mm alumina crucible, then place them in a muffle furnace, heat up to 900°C for pre-sintering, and keep warm for 8 Hours, take it out and re-grind it to make it evenly mixed. The second sintering is kept at 1550°C for 18 hours, and finally Cr 3+ : Ca 2 AlNbO 6 raw material.

[0029] 4CaCO 3 +Nb 2 o 5 +xCr 2 o 3 +(1-x)Al 2 o 3 →2Ca 2 Al 1-x Cr x NbO 6 +4CO 2 ↑

[0030] Grind and mix the synthesized raw materials evenly, put them into a Φ55mm×30mm iridium crucible, place them in a pulling furnace, and place them in a protective gas N 2 Under certain conditions, the growth temp...

Embodiment 2

[0033] Preparation of Cr by High Temperature Solid Phase Method 3+ : Ca 2 AlNbO 6 (Cr 3+ The doping concentration is 1.2at.%), and the raw material used is analytically pure Al 2 o 3 , CaCO 3 , Nb 2 o 5 and Cr 2 o 3 . Then weigh the materials according to the proportion of the following chemical reaction formula, grind and mix them evenly with an agate mortar, put them into a 50×50mm alumina crucible, then place them in a muffle furnace, heat up to 900°C for pre-sintering, and keep warm for 8 Hours, take it out and re-grind it to make it evenly mixed, and heat it for 15 hours under the condition of 1550°C for the second sintering, and finally get Cr 3+ : Ca 2 AlNbO 6 raw material.

[0034] 4CaCO 3 +Nb 2 o 5 +xCr 2 o 3 +(1-x)Al 2 o 3 →2Ca 2 Al 1-x Cr x NbO 6 +4CO 2 ↑

[0035] Grind and mix the synthesized raw materials evenly, put them into a Φ55mm×30mm iridium crucible, place them in a pulling furnace, and place them in a protective gas N 2 Under cer...

Embodiment 3

[0037] Preparation of Cr by High Temperature Solid Phase Method 3+ : Ca 2 AlNbO 6 (Cr 3+ The doping concentration is 5.0at.%), and the raw material used is analytically pure Al 2 o 3 , CaCO 3 , Nb 2 o 5 and Cr 2 o 3 . Then weigh the materials according to the proportion of the following chemical reaction formula, grind and mix them evenly with an agate mortar, put them into a 50×50mm alumina crucible, then place them in a muffle furnace, heat up to 900°C for pre-sintering, and keep warm for 8 After taking it out, grind it again to make it evenly mixed, and then sinter it for 12 hours under the condition of 1550°C, and finally get Cr 3+ : Ca 2 AlNbO 6 raw material.

[0038] 4CaCO 3 +Nb 2 o 5 +xCr 2 o 3 +(1-x)Al 2 o 3 →2Ca 2 Al 1-x Cr x NbO 6 +4CO 2 ↑

[0039] Grind and mix the synthesized raw materials evenly, put them into a Φ55mm×30mm iridium crucible, place them in a pulling furnace, and place them in a protective gas N 2 Under certain conditions, ...

PUM

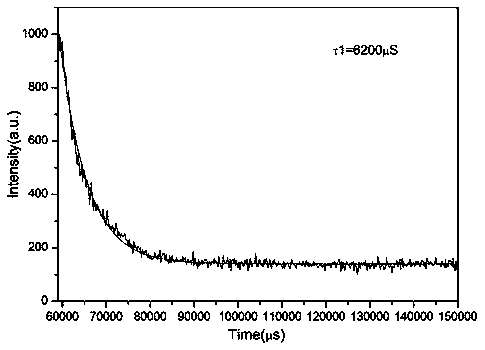

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com