Preparation method of nanoscale temperature-controlled slow-release fragrant microcapsules

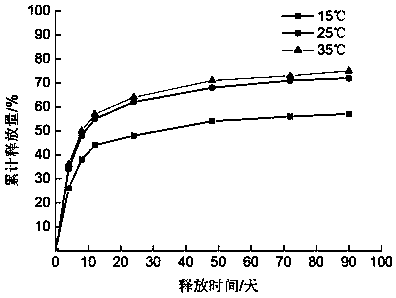

A microcapsule and slow-release technology, which is applied in the field of microcapsule preparation, can solve problems such as weak fragrance release rate and uneven influence of temperature on fragrance release rate, and achieve the effects of slowing down the release rate, reducing energy consumption, and strong physical adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

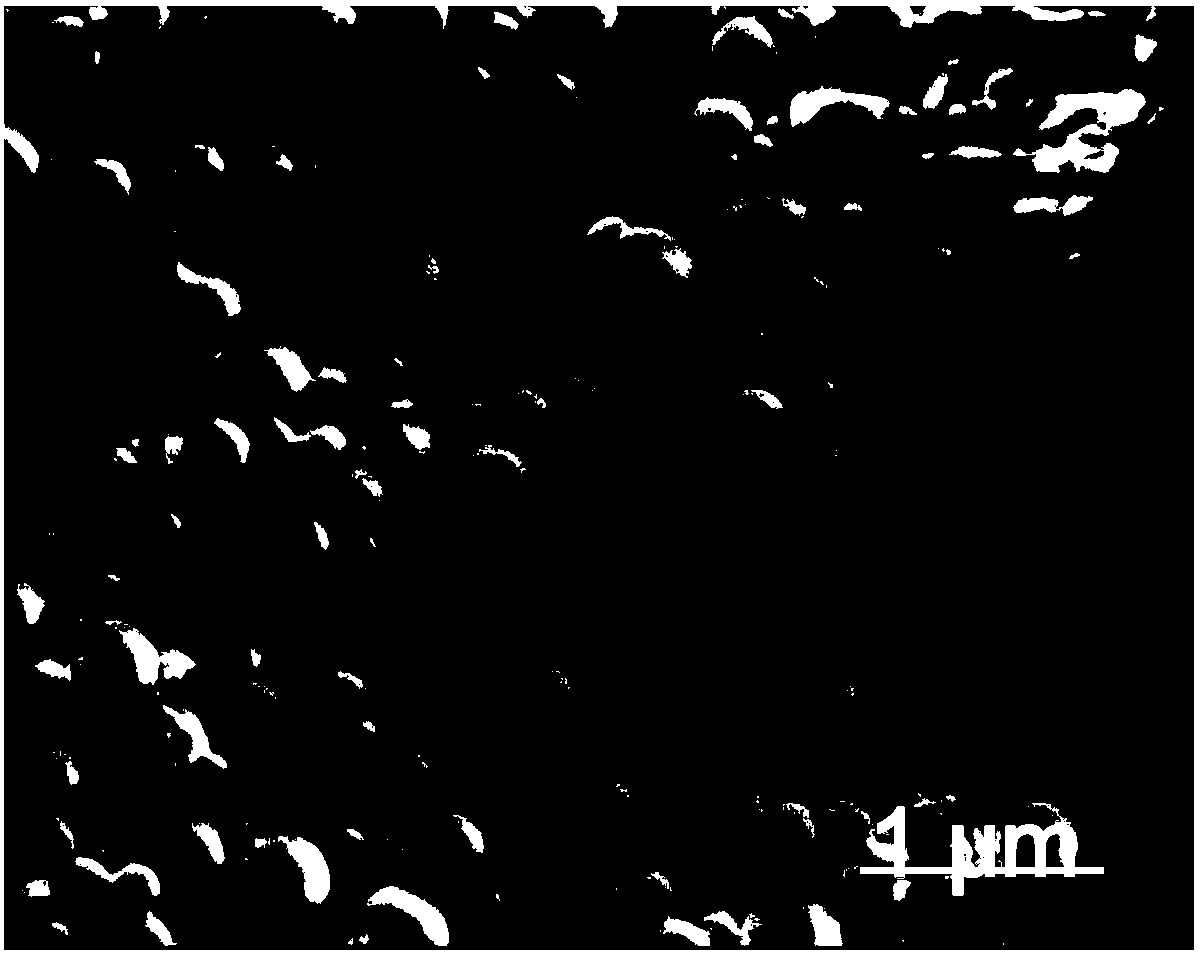

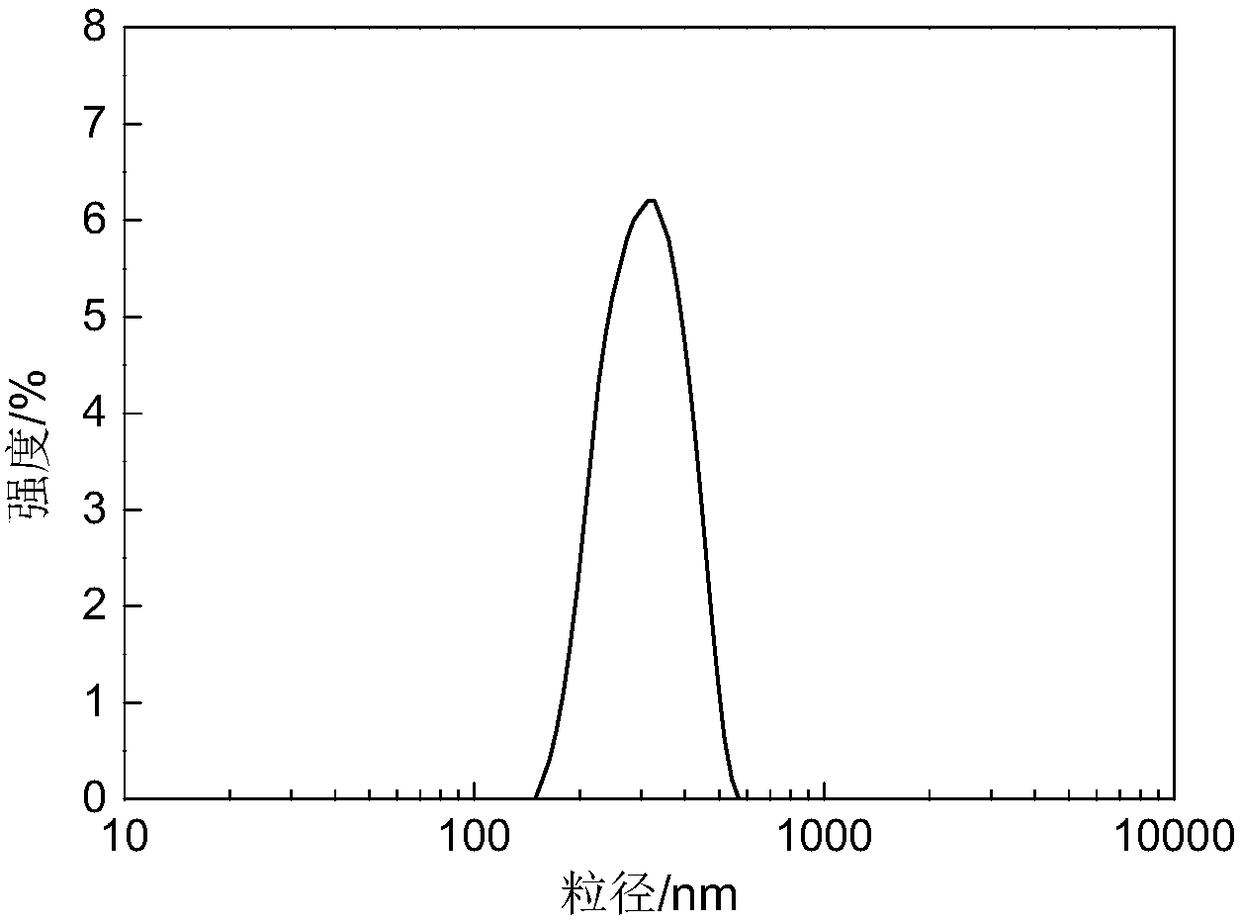

[0033] The invention provides a method for preparing nano temperature-controlled slow-release aromatic microcapsules, comprising the following steps:

[0034] (1) Preparation of raw materials: the nano temperature-controlled slow-release aromatic microcapsules include the following raw materials in weight fractions, 20-60 parts of phase change material carrier, 20-60 parts of essence, 30-90 parts of monomer, 0.3- 1.0 parts of initiator, 3-6 parts of emulsifier and 200-600 parts of water;

[0035] (2) Preparation of core material components: Mix the phase change material carrier and essence in the above ratio in a closed container at 30-35°C at 800-1200r / min to form a core material component;

[0036] (3) Preparation of oil phase components: Stir and mix the core material components prepared in (2) with the monomer and initiator in (1) in a closed container at 30-35° C. to form oil phase components;

[0037] (4) Preparation of water phase components: Stir and activate the emul...

Embodiment 1

[0046] A preparation method of nanometer temperature-controlled slow-release aromatic microcapsules, comprising the following steps:

[0047] (1) Raw material preparation: the nano-temperature-controlled slow-release fragrance microcapsules include the following raw materials in weight fractions, 40 parts of butyl stearate, 20 parts of lavender essence, 50 parts of methyl methacrylate, 10 parts of n-butyl acrylate, 0.9 parts of azobisisoheptanonitrile, 4.8 parts of sodium dodecylbenzenesulfonate and 480 parts of water;

[0048] (2) Preparation of the core material component: Stir and mix the above-mentioned butyl stearate and essence in a closed container at 32° C. at 1000 r / min to form the core material component;

[0049] (3) Preparation of oil phase components: combine the core material components prepared in (2) with methyl methacrylate, n-butyl acrylate and azobisisoheptanonitrile in (1) at 32°C in a closed container Stir and mix to form oil phase components;

[0050] (...

Embodiment 2

[0055] A preparation method of nanometer temperature-controlled slow-release aromatic microcapsules, comprising the following steps:

[0056] (1) Preparation of raw materials: the nano temperature-controlled slow-release aromatic microcapsules include the following raw materials in weight fractions, 40 parts of methyl stearate, 20 parts of rose essence, 50 parts of methyl methacrylate, 10 parts of n-butyl acrylate, 0.9 parts of azobisisoheptanonitrile, 4.8 parts of sodium dodecylbenzenesulfonate and 480 parts of water;

[0057] (2) Preparation of the core material component: Stir and mix the above-mentioned butyl stearate and essence in a closed container at 32° C. at 1000 r / min to form the core material component;

[0058] (3) Preparation of oil phase components: combine the core material components prepared in (2) with methyl methacrylate, n-butyl acrylate and azobisisoheptanonitrile in (1) at 32°C in a closed container Stir and mix to form oil phase components;

[0059] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com