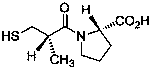

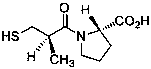

Method for determining impurity F in captopril tablets through high performance liquid chromatography

A technology of high-performance liquid chromatography and captopril tablets, which is applied in the field of high-performance liquid chromatography for the determination of impurity F in captopril tablets, can solve the problems of cumbersome operation, poor repeatability, and unstable measurement results, and achieve separation Good precision and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

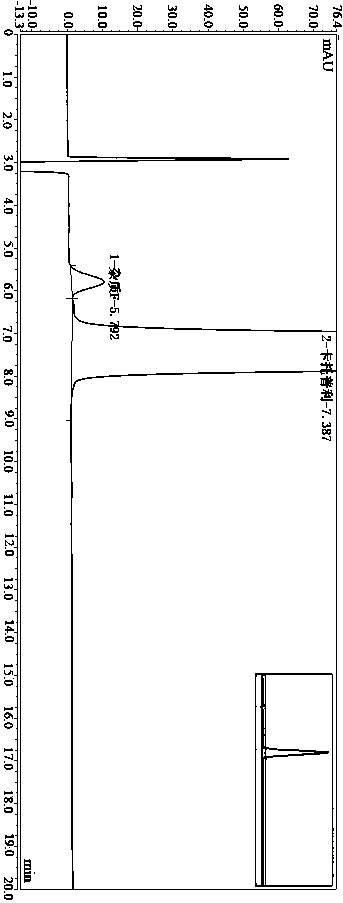

Image

Examples

Embodiment 1

[0044] A method for the determination of impurity F in captopril tablets by high performance liquid chromatography, comprising the steps:

[0045] (1) Preparation of captopril impurity F stock solution

[0046] Weigh 5mg of captopril impurity F, place it in a 50ml measuring bottle, add absolute ethanol to dissolve and dilute to the mark, shake well, and use it as captopril impurity F stock solution;

[0047] (2) Preparation of system suitability solution

[0048] Weigh 25mg of captopril reference substance, put it in a 10ml measuring bottle, add (1) 0.5ml, then add 4.5ml of absolute ethanol to dissolve, then dilute to the mark with n-hexane, shake well, and use it as a system suitability solution;

[0049] (3) Preparation of the test solution

[0050] Weigh an appropriate amount of fine powder of captopril tablets (approximately equivalent to 25mg of captopril), put it in a 10ml measuring bottle, add about 5ml of absolute ethanol, extract by ultrasonic vibration for 5min, le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com