Triboelectric nanogenerators, micromechanical sensors and sensing systems

A nanogenerator and sensor technology, applied in the field of sensors, can solve the problems of inability to accurately calculate the propagation speed of pulse waves, easy leakage of charges, inability to test surface fit, etc., to achieve wireless transmission and visual analysis, and improve sensitivity and noise. Compare and realize the effect of non-invasive monitoring technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

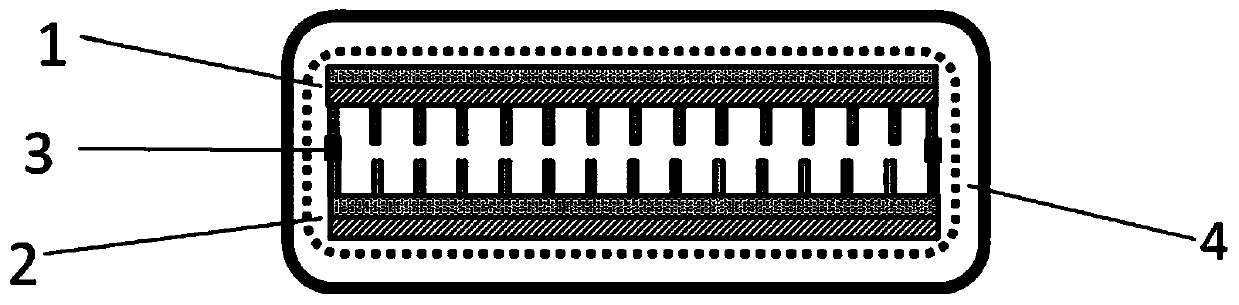

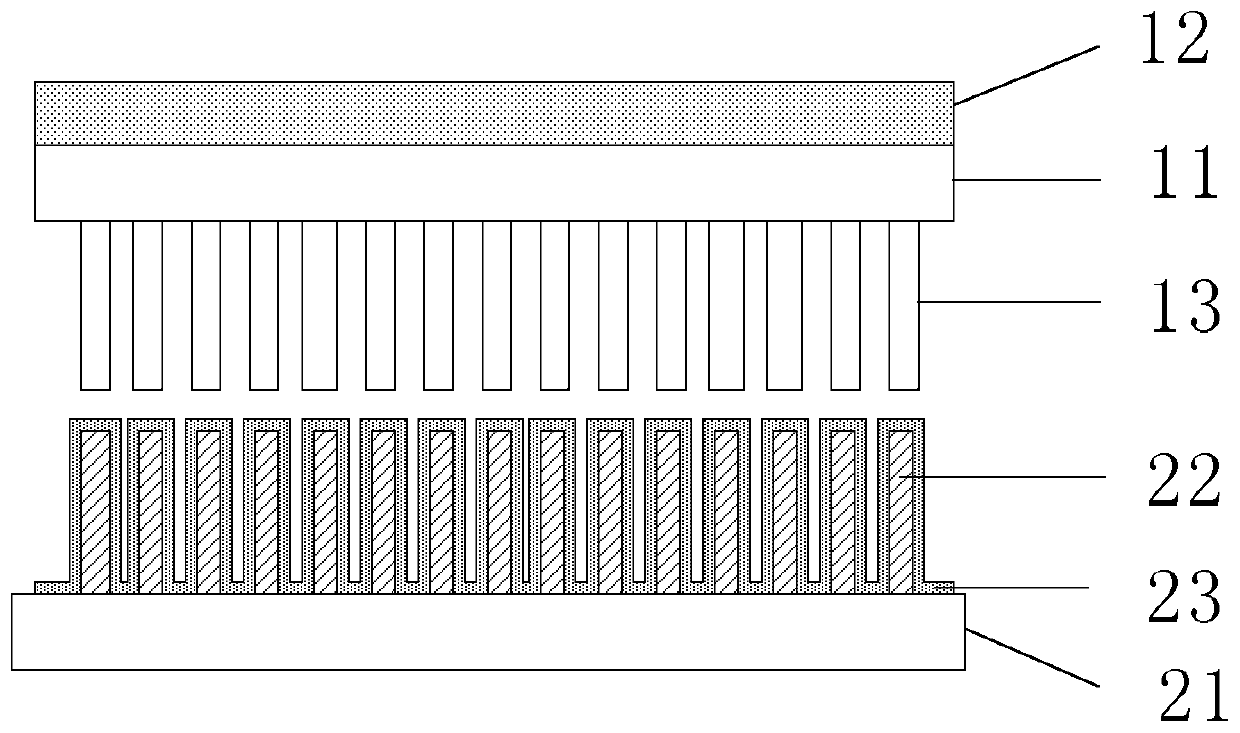

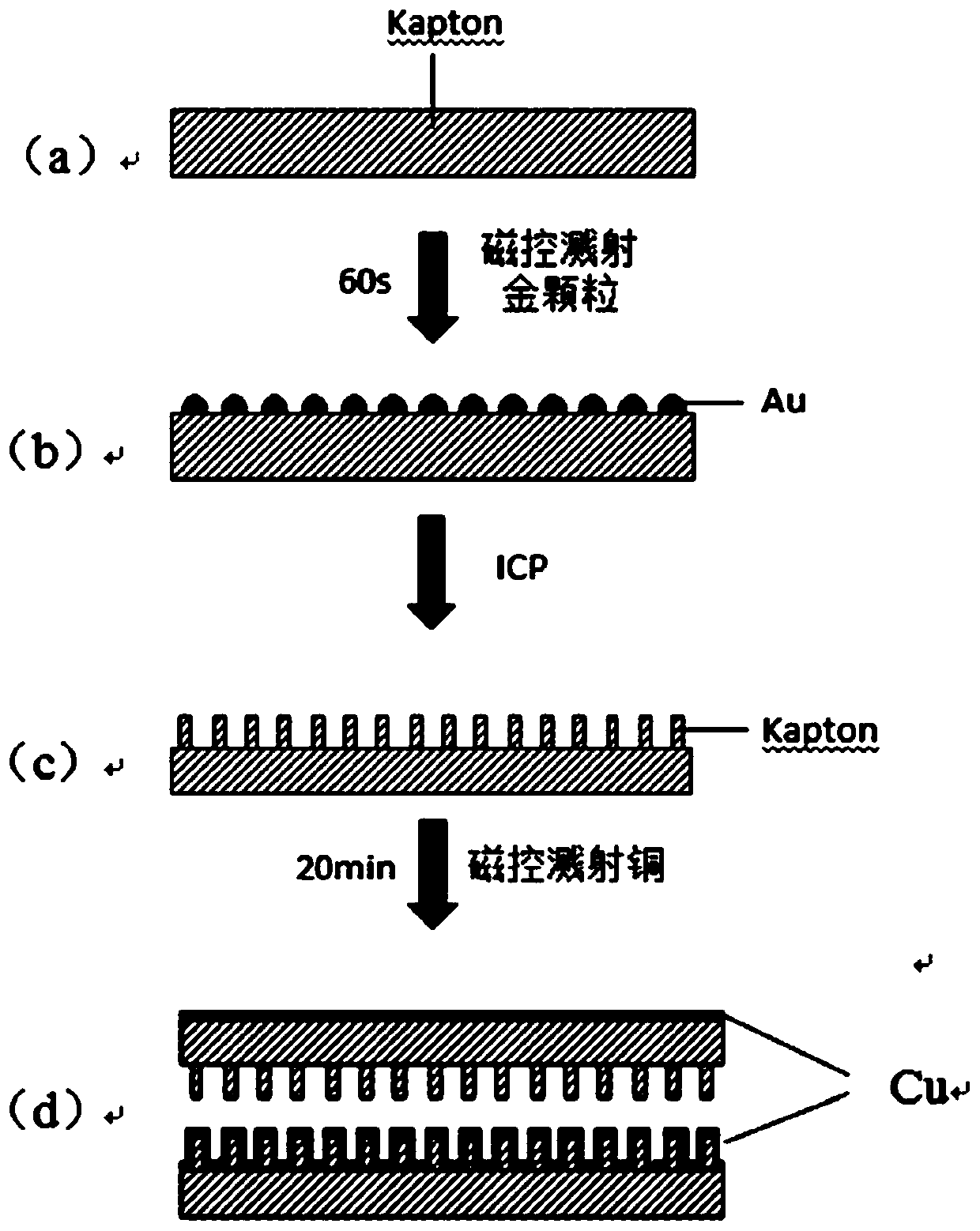

[0037] Before introducing the present invention, firstly, the design principle of the triboelectrostatic effect triboelectric nanogenerator will be described. The triboelectric nanogenerator is based on the different triboelectric properties of the surface materials of the two friction layers, and there is a difference in the ability to gain and lose electrons between the two. The friction layer material of the electrons gets electrons, so that the electrode layer attached to the two friction layer materials outputs electric signals to the outside. When the contact area between the two friction layers changes, an electrical signal will be output to the outside.

[0038] The triboelectric property of a material refers to the ability of the material to gain and lose electrons during friction or contact with other materials, that is, when two materials are in contact, one is positively charged and the other is negatively charged, indicating that the two materials gain and lose el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com