Preparation method of Ce-doped Ni-Fe-Ce ternary sulfide oxygen evolution catalyst

A ni-fe-ce, catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of expensive metal catalysts, difficulty in large-scale application, single performance, etc., to achieve Good catalytic oxygen production effect, low cost, simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

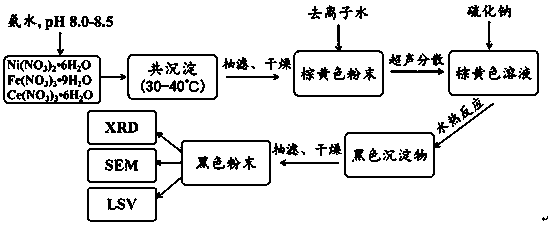

[0023] (the molar ratio of Ni, Fe and Ce is 1:1:1):

[0024] (1) Solution preparation and pH adjustment Weigh Ni(NO 3 ) 2 •6H 2 O, Fe(NO 3 ) 3 •9H 2 O, Ce(NO 3 ) 3 •6H 2 O (mass ratio is 1:1.39:1.49), add 100mL distilled water (solid (g)~liquid (mL) ratio is 1:10), stir until dissolved, then weigh a certain amount of sodium bicarbonate (the amount of the substance is 2 times of metal ions), continue stirring to dissolve to obtain a clear solution. Then, dilute aqueous ammonia was added dropwise to adjust the pH of the solution to 8.0.

[0025] (2) Co-precipitation reaction Then, the solution was placed at 35°C, and the stirring reaction was continued for 18 hours.

[0026](3) Separation and purification of the product Take out the reaction solution, filter it with suction, wash it with distilled water several times until the washing solution is neutral, and finally wash it twice with absolute ethanol, then dry it in an oven at 60°C for 12 hours, and finally grind it ...

Embodiment 2

[0033] (the molar ratio of Ni, Fe and Ce is 5:3:1):

[0034] (1) Solution preparation and pH adjustment Weigh Ni(NO 3 ) 2 •6H 2 O, Fe(NO 3 ) 3 •9H 2 O and Ce(NO 3 ) 3 •6H 2 O (mass ratio 1:0.83:0.30), add 100mL of distilled water, stir until dissolved, then weigh a certain amount of sodium bicarbonate (the amount of the substance is twice that of the metal ion), continue to stir and dissolve to obtain a clear solution. Then, dilute aqueous ammonia was added dropwise to adjust the pH of the solution to 8.5.

[0035] (2) Co-precipitation reaction Then, the solution was placed at 30°C, and the stirring reaction was continued for 24 hours.

[0036] (3) Product separation and purification Take out the reaction solution, perform suction filtration, wash with distilled water several times in sequence until the washing solution is neutral, and finally wash twice with absolute ethanol to obtain a brown-yellow precipitate, and then place the brown-yellow precipitate in Dry it ...

Embodiment 3

[0043] (The molar ratio of Ni, Fe and Ce is 5:1:3):

[0044] (1) Solution preparation and pH adjustment Weigh Ni(NO 3 ) 2 •6H 2 O, Fe(NO 3 ) 3 •9H 2 O, Ce(NO 3 ) 3 •6H 2 Add O (mass ratio 1:0.28:0.89) into 100mL of distilled water, stir until dissolved, then weigh a certain amount of sodium bicarbonate (the amount of the substance is twice that of the metal ion), continue to stir and dissolve to obtain a clear solution. Then, dilute aqueous ammonia was added dropwise to adjust the pH of the solution to 8.5.

[0045] (2) Co-precipitation reaction Then, the solution was placed at 40°C, and the stirring reaction was continued for 12 hours.

[0046] (3) Product separation and purification Take out the reaction solution, perform suction filtration, wash with distilled water several times in sequence until the washing solution is neutral, and finally wash twice with absolute ethanol to obtain a brown-yellow precipitate, and then place the brown-yellow precipitate in Dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overpotential | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com