Copper suppression inhibitor, preparation method and copper-containing mineral flotation method

A copper inhibitor and mineral technology, applied in the field of preparation, copper inhibitor, and copper-containing mineral flotation, can solve problems such as environmental hazards and pollution, and achieve the effects of high safety, good inhibition effect and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

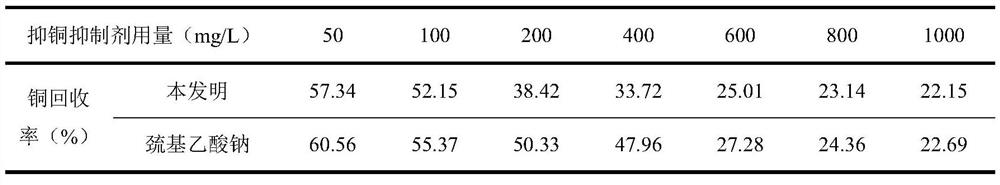

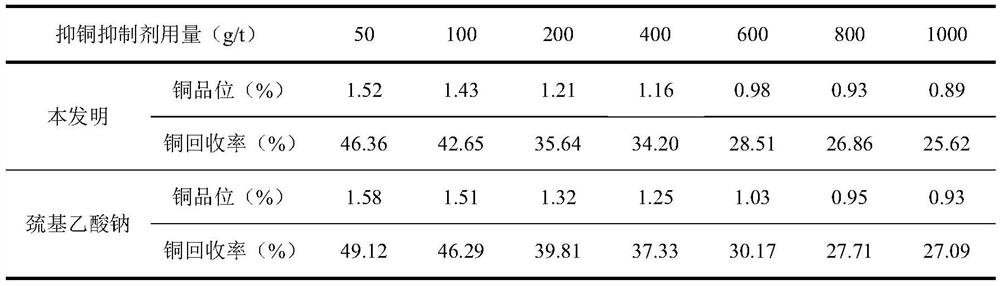

Examples

Embodiment 1

[0031] The present embodiment provides a copper inhibition inhibitor, which is made of the following raw materials in parts by weight: 40 parts of urea, 40 parts of sodium carbonate, 10 parts of sodium hydroxide, and 10 parts of potassium ferrocyanide .

[0032] This embodiment also provides a preparation method of copper inhibition inhibitor, the preparation method adopts the formula of copper inhibition inhibitor as described above, and the method comprises the following steps:

[0033] Step 1: Put all the weighed components into the grinding mixer for grinding and mixing, until the fineness of any component is less than 200 mesh, the grinding is completed;

[0034] Step 2: Put the ground and mixed raw materials into a corundum crucible or an ark, and perform manual compaction;

[0035] Step 3: Put the corundum crucible or ark filled with raw materials into the tube atmosphere furnace, close the equipment, turn on the vacuum pump, and pump out all the air in the tube. The ...

Embodiment 2

[0045] The present embodiment provides a copper inhibition inhibitor, which is made of the following raw materials in parts by weight: 35 parts of urea, 40 parts of sodium carbonate, 10 parts of sodium hydroxide, and 15 parts of potassium ferrocyanide .

[0046] The preparation method of the copper inhibition inhibitor of this embodiment is the same as that of Example 1.

[0047] The flotation method of the copper-containing mineral of this embodiment is the same as that of Embodiment 1.

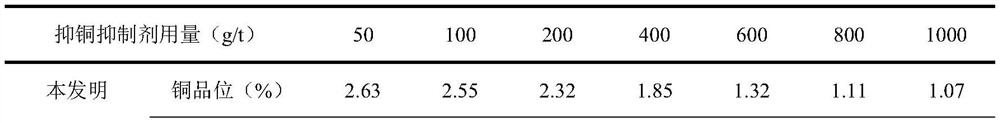

Embodiment 3

[0049] The present embodiment provides a copper inhibition inhibitor, which is made of the following raw materials in parts by weight: 40 parts of urea, 40 parts of sodium carbonate, 5 parts of sodium hydroxide, and 15 parts of potassium ferrocyanide .

[0050] The preparation method of the copper inhibition inhibitor of this embodiment is the same as that of Example 1.

[0051] The flotation method of the copper-containing mineral of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com