Method for removing silicon dioxide in water

A silicon dioxide and aluminum hydroxide technology, which is applied in the fields of chemical instruments and methods, water pollutants, water/sewage treatment, etc. Unsatisfactory silicon oxide removal effect and other problems, to achieve good industrial application prospects, improve recycling application value, and remove silicon dioxide thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

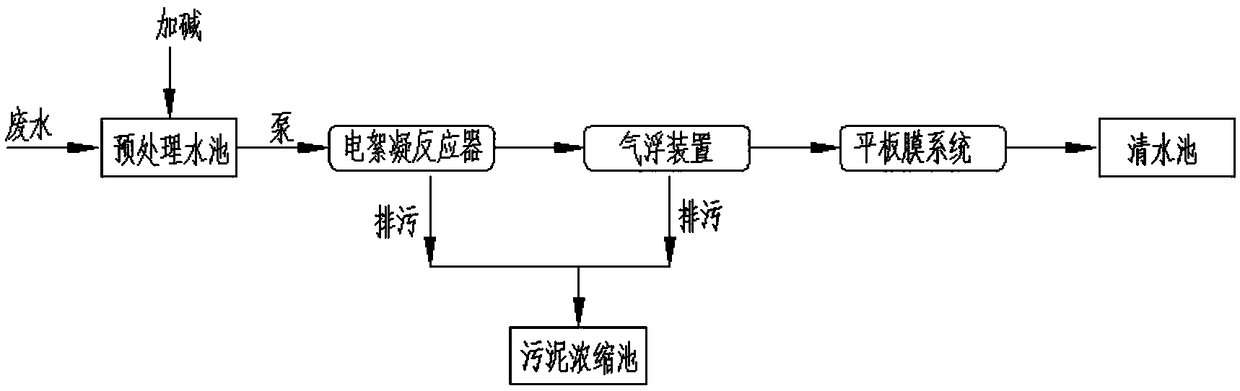

[0028] Such as figure 1 shown, the 0.5m 3 The reverse osmosis concentrated water is pretreated by adding alkali. The specific method is to add sodium hydroxide solution to the reverse osmosis concentrated water, and control the pH of the aqueous solution after adding alkali = 8-10, and then lift it into the electroflocculation reactor through the pump for electrolysis reaction , taking the area of a single piece as 100cm 2 The aluminum sheet is used as the pole plate, five sets of cathode and anode plates are inserted into the wastewater pool to be treated together, the anode and the cathode are kept facing each other, and the distance between each set of cathode and anode plates is controlled to be 10mm, and a current of 48V / 29A is passed through, and the electrolysis reaction lasts for 10 minutes. , and then enter the air flotation device to separate the suspended solids, and control the aeration flow rate of the air flotation device to be 30m 3 / h. Finally, the aqueous...

Embodiment 2

[0034] Take 1m of wastewater from a catalyst factory in a chemical company 3 Alkali pretreatment is carried out, the specific method is to add calcium hydroxide solution to the wastewater, and control the pH of the aqueous solution after adding alkali = 10-12, and then lift it into the electrocoagulation reactor through the pump to carry out electrolysis reaction. 100cm 2 The aluminum sheet is used as the pole plate, five sets of cathode and anode plates are inserted into the wastewater pool to be treated together, the anode and the cathode are kept facing each other, and the distance between each set of cathode and anode plates is controlled to be 10mm, and a current of 50V / 35A is passed through, and the electrolysis reaction lasts for 12 minutes. , and then enter the air flotation device to separate the suspended solids, and control the aeration flow rate of the air flotation device to 45m 3 / h. Finally, the aqueous solution treated by the air flotation device enters the m...

Embodiment 3

[0040] Take 1.5m of wastewater from a catalyst factory in a chemical company 3, carry out alkali pretreatment, specifically add calcium hydroxide to the wastewater, and control the pH of the aqueous solution after adding alkali to 12-14, and then lift it into the electrocoagulation reactor through a pump to carry out electrolysis reaction. The area of a single piece is 100cm 2 The aluminum sheet is used as the pole plate, five sets of cathode and anode plates are inserted into the wastewater pool to be treated together, the anode and the cathode are kept facing each other, and the distance between each set of cathode and anode plates is controlled to be 10mm, and a current of 60V / 40A is passed through, and the electrolysis reaction is 30min , and then enter the air flotation device to separate the suspended solids, and control the aeration flow rate of the air flotation device to be 30-40m 3 / h. Finally, the aqueous solution treated by the air flotation device enters the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com