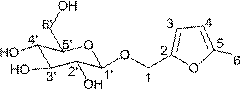

Preparation method and application of 5-methyl furfuryl alcohol-beta-D-glucoside

A technology of methyl furfuryl alcohol and glucoside, which is applied in the field of tobacco flavors, can solve the problems of easy volatilization of 5-methyl furfuryl alcohol and easy loss of flavor, and achieve the effects of simple post-processing, reducing miscellaneous gas, and improving volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

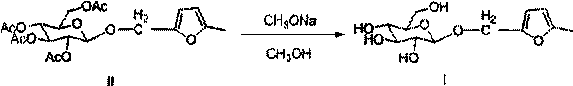

[0037] The preparation method of 5-methylfurfuryl alcohol-β-D-glucoside of this embodiment is:

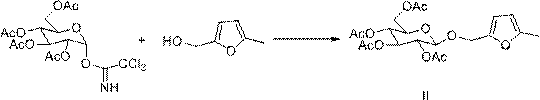

[0038] (1) Synthesis of 5-methylfurfuryl alcohol-β-D-tetraacetyl glucoside (Ⅱ):

[0039] Dissolve 0.56 g (5 mmol) of 5-methylfurfuryl alcohol and 2.98 g (6 mmol) of trichloroacetimide ester sugar in 15 mL of dry dichloromethane, add 1 g of freshly baked 4 Å molecular sieve, and stir at room temperature After 10 min, cool to -20 ℃, add 1.41g (10 mmol) BF 3 •Et 2 O continued to incubate the reaction for 2 h, and TLC detected the progress of the reaction. After the reaction, 30 mL of dichloromethane was added, shaken, and separated. The organic phase was washed 3 times with saturated sodium carbonate solution and 3 times with saturated brine. The organic phase was separated, dried with anhydrous sodium sulfate overnight, filtered, and depressurized. After concentration, it is separated and purified by silica gel column chromatography [ V (Petroleum ether): V (Ethyl acetate)=4:1] to obtain...

Embodiment 2

[0049] The preparation method of 5-methylfurfuryl alcohol-β-D-glucoside of this embodiment is:

[0050] (1) Synthesis of 5-methylfurfuryl alcohol-β-D-tetraacetyl glucoside (Ⅱ):

[0051] Dissolve 0.56 g (5 mmol) of 5-methylfurfuryl alcohol and 4.96 g (10 mmol) of trichloroacetimide ester sugar in 20 mL of dry dichloromethane, add 2 g of freshly baked anhydrous calcium sulfate, at room temperature Stir for 10 min and then cool to -20 ℃, add 2.12 g (15 mmol) BF 3 •Et 2 O continued to incubate the reaction for 1 h, and TLC checked the progress of the reaction. After the reaction, add 30 mL of dichloromethane, shake, and separate. The organic phase was washed 4 times with saturated sodium carbonate solution and 4 times with saturated brine. The organic phase was separated, dried with anhydrous sodium sulfate overnight, filtered, and depressurized. After concentration, it is separated and purified by silica gel column chromatography [ V (Petroleum ether): V (Ethyl acetate)=4:1], 1.70 g ...

Embodiment 3

[0057] The preparation method of 5-methylfurfuryl alcohol-β-D-glucoside of this embodiment is:

[0058] (1) Synthesis of 5-methylfurfuryl alcohol-β-D-tetraacetyl glucoside (Ⅱ):

[0059] Dissolve 0.56 g (5 mmol) of 5-methylfurfuryl alcohol and 3.72 g (10 mmol) of trichloroacetimide ester sugar in 20 mL of dry dichloromethane, add 2 g of freshly baked anhydrous calcium sulfate, at room temperature Stir for 10 min and then cool to -20 ℃, add 1.41 g (15 mmol) BF 3 •Et 2 O continued to incubate the reaction for 2 h, and TLC detected the progress of the reaction. After the reaction, add 30 mL of dichloromethane, shake, and separate. The organic phase was washed 5 times with saturated sodium carbonate solution and 5 times with saturated brine. The organic phase was separated, dried with anhydrous sodium sulfate overnight, filtered, and depressurized. After concentration, it is separated and purified by silica gel column chromatography [ V (Petroleum ether): V (Ethyl acetate)=3:1], 1.75g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com